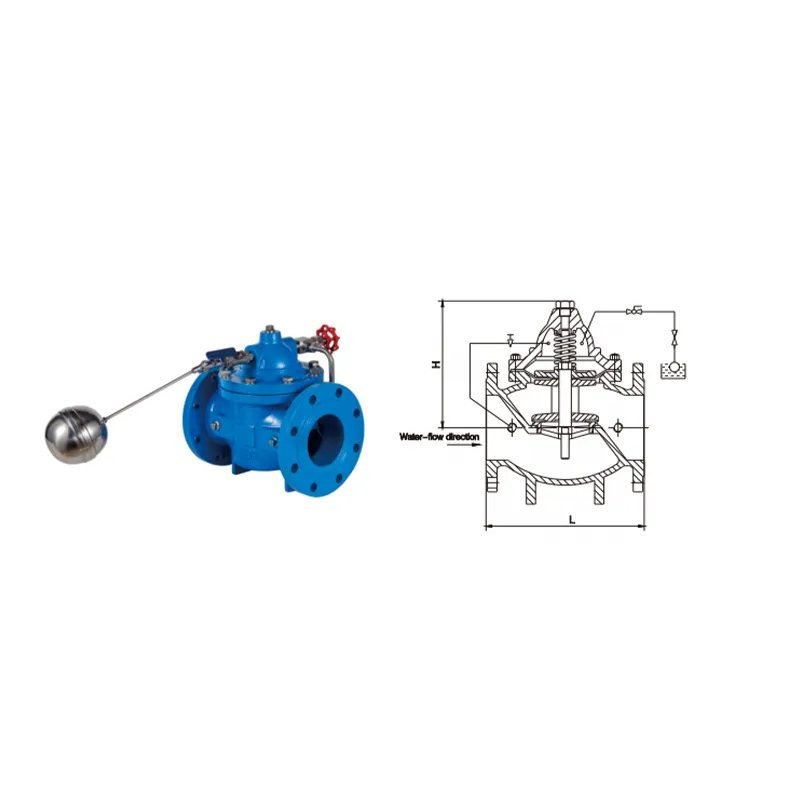

100X Remote Control Floating Valve

100X Remote Control Floating Valve Purpose

Able to control the liquid surface of a water tower or pool. Suitable for the automaic water supply system of various water pools and towers in industrial and mineral enterprises and civil buildings

100X Remote Control Floating Valve Principle

The upper cavitly of the master valve is connected to the controlling floating ball and the floating ball valve is fixed on the liquid surface of a water tower. The floating ball valve is opened along with the lowering of the liquid surface to make the master valve opened to supply water to the water tower; and, when the liquid surface rises to the floating ball valve position, the floating ball valve is closed, so is the master one to stop water supply to the water tower.

100X Remote Control Floating Valve Definition and Components

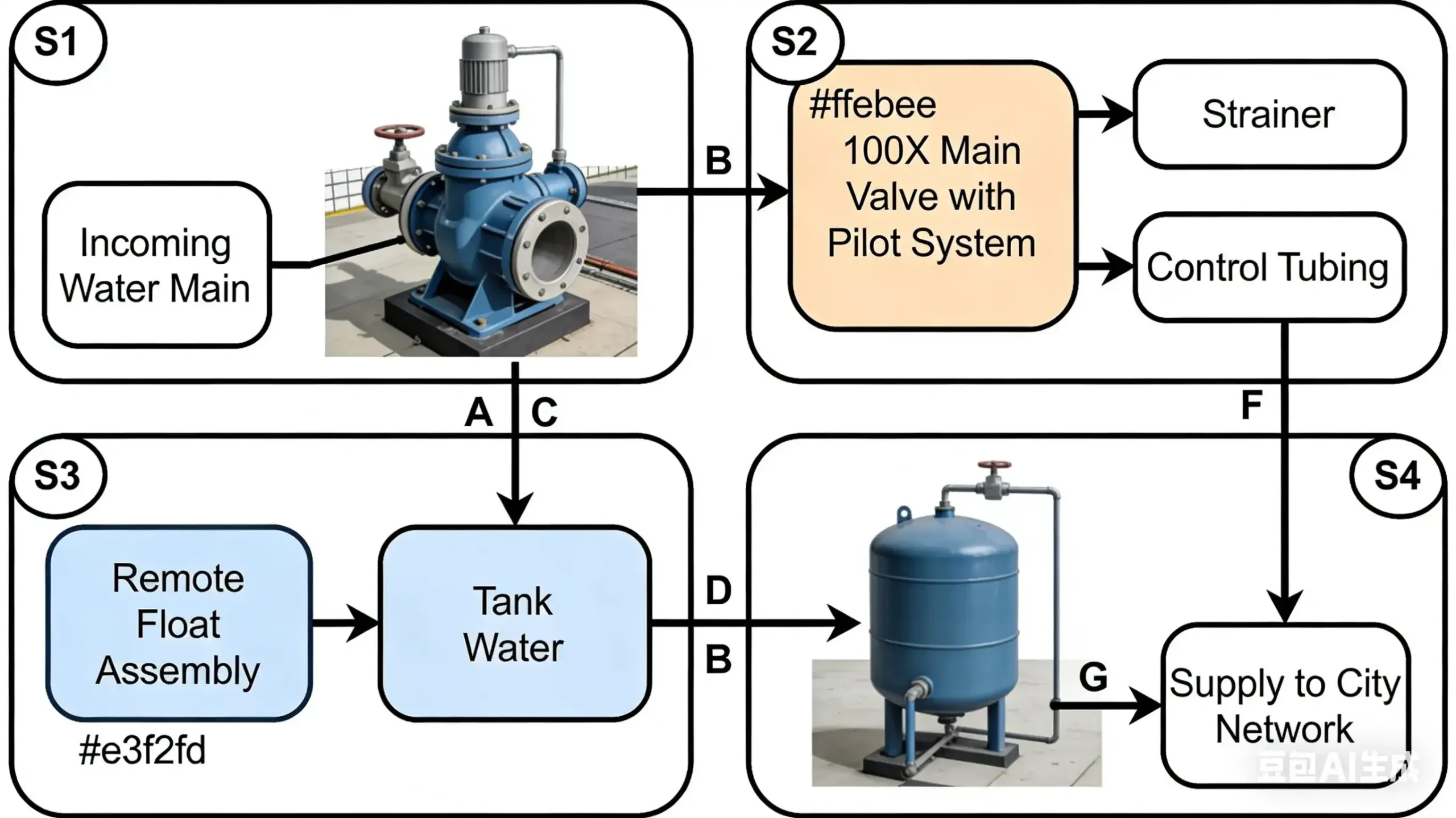

A 100X Remote Control Floating Valve is a hydraulically operated automatic control valve used to maintain a specific water level in storage tanks or reservoirs, such as those in municipal water towers or building water systems . It does not require external electricity, using pipeline water pressure instead .

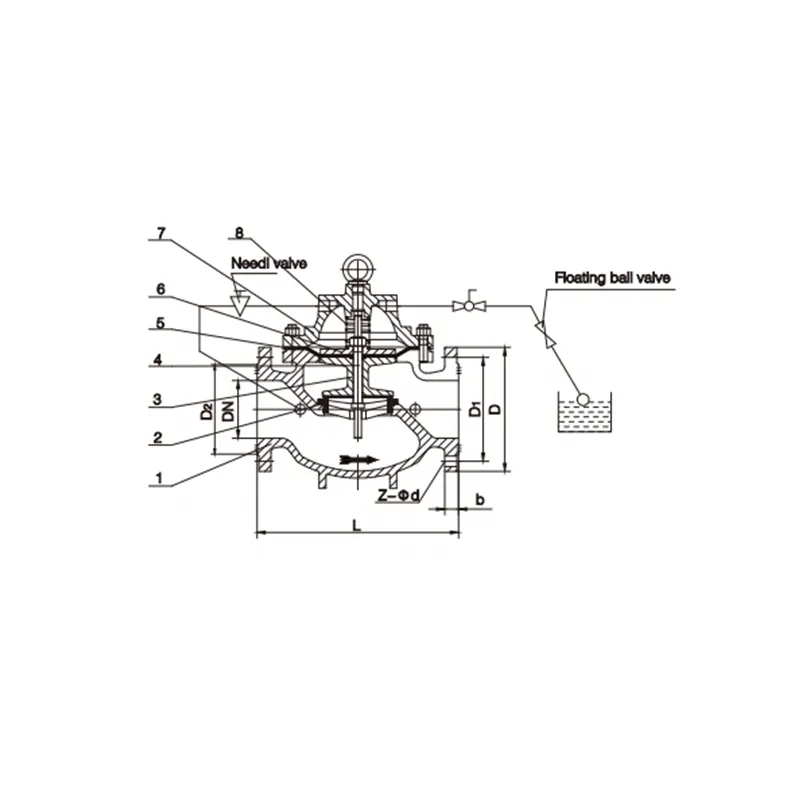

Remote Control Float Valve Main Parts & How It Works

The valve is a system consisting of a main valve body and a pilot control system.

- Main Valve Body: Houses the diaphragm or piston, which is the primary actuator that moves to open or close the main flow port.

- Pilot Control System: This is the "brain" and typically includes:

- Remote Float & Pilot Valve: Mounted inside the tank to sense water level.

- Control Tubing: Connects the float to the pilot system on the main valve.

- Needle Valves: For fine-tuning the opening and closing speeds.

- Ball Valve: To isolate the pilot system for maintenance.

- Micro-Filter: Protects the sensitive pilot system from pipe debris.

- How it works: When the tank water level is low, the float drops, opening the pilot valve. This releases pressure from above the main diaphragm/piston, causing the main valve to open and refill the tank. When the water reaches the set level, the float rises, closing the pilot valve. Water pressure then builds up in the upper chamber, forcing the main valve to close and stop the inflow .

Here is a diagram showing how the system is typically installed to control a municipal water tower:

Role, Characteristics, and Application Scenarios of 100X Remote Control Floating Valve in Pipelines

Its core function is automatic level control. Key operational features are:

- Hydraulic Operation: Uses the pressure of the water itself, requiring no electricity .

- Accurate Control: Maintains water level precisely regardless of incoming water pressure variations .

- Flexible Installation: The main valve and float can be installed separately to suit different layouts .

- Two Actuator Types: A diaphragm actuator is recommended for pipelines DN450 (18 inches) and smaller for quick response, while a piston actuator is suggested for DN500 (20 inches) and larger for greater durability .

- Reliable & Low-Maintenance: Simple, durable design. Maintenance typically involves checking the diaphragm and springs, which are considered consumable parts .

100X Remote Control Floating Valve Standards: Materials, Design, and Connections

When specifying this valve, you must define its construction and the standards it adheres to.

| Category | Key Standards & Common Options | Details & Notes |

| Material Standards | Body/Valve Cover: ASTM A216 WCB (Carbon Steel), Ductile Iron, or Stainless Steel (304/316) . Trim/Seats: Copper Alloy . Seals/Diaphragm: NBR (Nitrile Rubber), EPDM . |

Materials must match the fluid and environment. For potable water, ensure materials have NSF/61 or similar certification. |

| Design & Pressure Ratings | Common Ratings: PN10, PN16, PN25 (1.0, 1.6, 2.5 MPa) . Standard Testing: Shell Test at 1.5x PN, Seal Test at 1.1x PN . |

The valve's pressure rating must be higher than the system's maximum working pressure. |

| Connection Standards | Flange Connection is most common . | The flange dimensions (bolt hole spacing) must match your pipeline's standards (e.g., GB, ANSI, DIN) . |

How to Select 100X Remote Control Floating Valve

Use this list to ensure you cover all bases when ordering:

Control Valve for Water Define Core Specifications:

- Valve Size (DN) and Pressure Rating (PN).

- Actuator Type: Diaphragm (≤DN450) or Piston (≥DN500).

- Body & Seal Materials (confirm fluid compatibility).

- Connection Type & Standard (e.g., Flange to ANSI B16.5).

- Request Documentation: Require detailed technical drawings, material certifications, and factory test reports.

- Supplier Qualification: Verify the manufacturer's experience, quality certifications (like ISO 9001), and request reference projects.

- Clarify Commercial Terms: Price (FOB/CFR), lead time, payment terms, warranty (typically 12-24 months), and spare parts availability.

- Pre-Shipment Inspection for Export 100X Remote Control Floating Valve and Key Considerations

A thorough inspection is critical before shipment. You should refer to professional standards like SN/T 1455-2012for general export valve inspection rules . Follow these key stages:

| Inspection Stage | Key Activities | Acceptance Criteria |

| Stage 1: Doc Review | - Check Material Test Certs (MTCs) for body, seals, etc. - Review approved technical drawings. - Verify factory pressure test reports. |

All documents must be complete, stamped, and match the purchase order. |

| Stage 2: Visual & Dimensional | - Inspect castings for defects. - Measure face-to-face length and flange dimensions (diameter, bolt holes). - Check markings (size, pressure, material, flow arrow). |

Dimensions within tolerances. No cracks or severe porosity. Clear and correct markings. |

| Stage 3: Pressure Testing | Witness if possible: 1. Shell Strength Test: Apply 1.5x PN pressure to the closed valve . 2. Seal Tightness Test: Apply 1.1x PN pressure, check for leaks at the seat . |

No visible leakage, weeping, or permanent deformation. |

| Stage 4: Function Simulation | - Connect the pilot tube to a temporary float or manual switch. - Simulate low level (open pilot) to see main valve open. - Simulate high level (close pilot) to see main valve close. |

The valve must open and close smoothly, fully, and in a controlled manner. |

| Stage 5: Packaging & Preservation | - Ensure internal parts are dry and clean. - Confirm all ports are sealed with protective caps. - Check that crating is sturdy for export. |

Valve must be protected from moisture, corrosion, and physical damage. |

Water Valves Critical Precautions:

- Sampling: For batch orders, define an Acceptable Quality Level (AQL) sampling plan (e.g., inspect 10% randomly).

- Rejection Criteria: Clearly state grounds for rejection (e.g., failed pressure test, wrong material).

- Third-Party Inspection: For critical projects, consider hiring an independent inspection company.

100X Remote Control Floating Valve Main dimensions(mm)

| DN | Length | Main dimensions | |||||||||

| 1.0MPa | 1.6MPa | 2.5MPa | |||||||||

| mm | L | D | D1 | n -d | D | D1 | n -d | L | D | D1 | n -d |

| 50 | 218 | 160 | 125 | 4-18 | 160 | 125 | 4-18 | 235 | 160 | 125 | 4-19 |

| 65 | 235 | 180 | 145 | 4-18 | 180 | 145 | 4-18 | 240 | 180 | 145 | 8-19 |

| 80 | 250 | 195 | 160 | 8-18 | 195 | 160 | 8-18 | 290 | 195 | 160 | 8-19 |

| 100 | 290 | 220 | 180 | 8-18 | 220 | 180 | 8-18 | 325 | 230 | 190 | 8-23 |

| 125 | 325 | 245 | 210 | 8-18 | 245 | 210 | 8-18 | 340 | 270 | 220 | 8-28 |

| 150 | 360 | 282 | 240 | 8-22 | 282 | 240 | 8-22 | 400 | 300 | 250 | 8-28 |

| 200 | 425 | 335 | 295 | 8-22 | 335 | 295 | 12-22 | 465 | 360 | 310 | 12-28 |

| 250 | 508 | 400 | 350 | 12-22 | 400 | 355 | 12-26 | 555 | 430 | 370 | 12-31 |

| 300 | 590 | 445 | 400 | 12-22 | 460 | 410 | 12-26 | 625 | 485 | 430 | 16-31 |

| 350 | 647 | 505 | 460 | 16-22 | 520 | 470 | 16-26 | ||||

| 400 | 720 | 565 | 515 | 16-26 | 580 | 525 | 16-30 | ||||

| 450 | 743 | 615 | 565 | 20-26 | 640 | 585 | 20-30 | ||||

| 500 | 782 | 670 | 620 | 20-26 | 715 | 650 | 20-34 | ||||

| 600 | 917 | 780 | 725 | 20-30 | 840 | 770 | 20-36 | ||||

Note:1. Other specifications and flange standards are available upon request.

- Design and specifications are subject to change without prior notice.

.png)

.png)