2025 Water Supply and Fire Protection Valve Selection Guide: Avoid These 3 Common Mistakes to Ensure System Safety and Efficiency

December 18, 2025

In water supply and fire protection systems, valves are often small components with a critical role.

They control flow, pressure, and isolation, making them the true “heart” of the system. A single wrong valve choice can lead to leakage, water damage, pressure instability, or even complete failure of a fire protection system when it matters most.

As system standards rise in 2025, fire valve selection is no longer a simple purchasing decision. It requires a clear understanding of materials, parameters, and certifications. This guide highlights three common mistakes in valve selection and provides practical solutions to help you choose the right product with confidence.

Mistake One: Focusing Only on Price and Ignoring Material Durability

Price is often the first factor buyers consider.

However, in water and fire protection projects, material quality directly affects service life and system safety.

Different Environments Demand Different Valve Materials

- Ductile Iron Valves

Widely used in municipal water systems and fire networks. They offer good strength and cost efficiency, especially when combined with proper internal coating for corrosion protection. - Bronze Valves

Suitable for smaller diameters and clean water applications. They provide good corrosion resistance but may not perform well under high pressure or large flow conditions. - Stainless Steel Valves

Recommended for corrosive water, chemical exposure, or high hygiene requirements. They offer excellent resistance but come with higher initial cost.

In high-pressure fire systems, material strength becomes even more critical. Inferior materials may deform or fail under pressure spikes, creating serious safety risks.

Low purchase cost often means higher long-term maintenance and replacement expenses. Choosing the right material from the beginning reduces downtime and protects the entire system.

Mistake Two: Incorrect Valve Parameters Reduce System Efficiency

A valve that “fits” physically may still be wrong for the system.

Parameter mismatch is a hidden issue that affects performance over time.

Key Parameters That Must Match the System

- Nominal Diameter (DN)

A mismatch between valve and pipeline diameter increases flow resistance and pressure loss. - Pressure Rating (PN)

The valve’s rated pressure must meet or exceed actual operating pressure. Underrated valves shorten service life and increase failure risk. - Flow Characteristics

Gate valves, globe valves, and butterfly valves behave differently. Choosing the wrong type can limit flow or reduce control accuracy.

In water supply valve selection, improper sizing can reduce efficiency.

In fire protection systems, poor parameter matching can delay water delivery during emergencies.

A valve should always be selected as part of a complete system, not as an isolated component.

Mistake Three: Missing Certifications Create Hidden Project Risks

Certification is not optional, especially for fire protection systems.

Fire Protection Valve Certification Is Mandatory

Fire valves must meet strict international and local requirements, including:

- FM Approval

- UL Listing

- VdS Certification

- CCC Certification (for applicable markets)

Without proper certification:

- Project acceptance may fail

- Insurance approval can be rejected

- System reliability becomes questionable

Water Supply Valves Also Require Compliance

Water valves must meet:

- Drinking water safety standards

- Non-toxic material requirements

- Coating and sealing regulations

Using uncertified valves may save cost upfront but can lead to legal, safety, and operational problems later.

High-Pressure Valve Materials: What You Should Know

High-pressure environments place extra demands on valve bodies, stems, and sealing components.

Key considerations include:

- Material tensile strength

- Internal coating quality

- Stem design and sealing performance

For high-pressure water or fire systems, ductile iron with reinforced structure or stainless steel designs are often preferred. Material selection must align with pressure, temperature, and medium to ensure long-term stability.

Why Choose Fuid Tech Group as Your Valve Supplier

As an experienced valve and pipe fitting supplier, Fuid Tech Group focuses not only on product supply but also on correct application.

All valves we provide:

- Comply with international and domestic standards

- Offer complete certification and technical documentation

- Support water supply and fire protection applications

- Meet requirements for high-pressure systems

Our technical team helps customers match valve materials, parameters, and certifications to real project conditions. This approach reduces risk and improves system reliability.

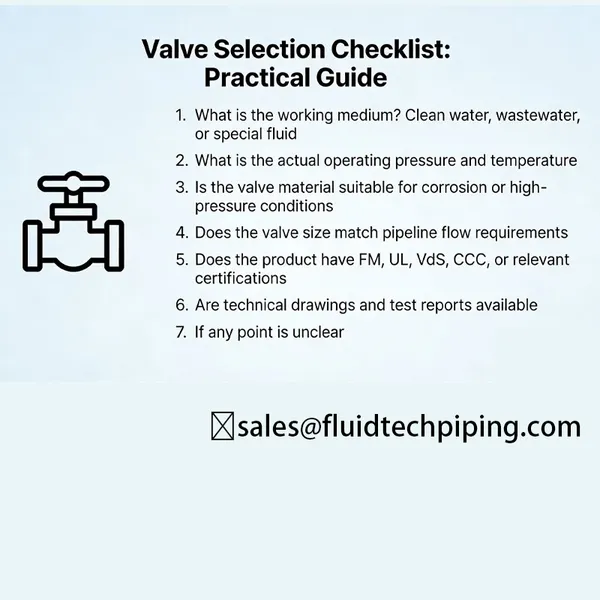

To explore our valve solutions or speak with a technical engineer, visit our product pages or contact our team directly.

.png)

.png)