3-Piece Threaded Ball Valve

3-Piece Threaded Ball Valve Definition and Components

What is a 3-Piece Threaded Ball Valve and its main parts?

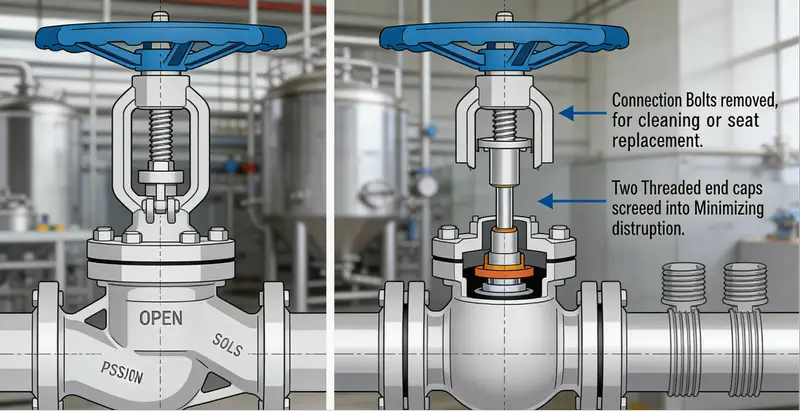

A 3 Piece Threaded Ball Valve is a versatile and robust quarter-turn valve designed for on/off and flow diversion service. Its key feature is a body constructed from three separate pieces: a central body section containing the ball and seats, and two end caps (or pipe ends). These three sections are secured together by bolts or long through-rods. This design allows for easy disassembly and maintenance without removing the valve from the pipeline, as the central section can be lifted out while the end caps remain threaded into the pipe.

Main Parts:

- Three-Piece Body Assembly: Comprises two end caps with threaded connections (NPT/BSP) and a center body section.

- Ball: A rotating sphere with a bore, typically chrome-plated or made of stainless steel for durability.

- Stem: A shaft connected to the ball, sealed to prevent leakage.

- Seats: Sealing rings (PTFE, PEEK, metal) that create a seal between the ball and the body.

- Body Seals/Gaskets: Seals placed between the mating flanges of the center body and end caps.

- Connection Bolts/Through-Rods: Long bolts or studs that clamp the three body sections together.

- Handle/Lever: For manual operation.

Role, Characteristics, and Application Scenarios of 3-Piece Threaded Ball Valve in Pipelines

Functions, Operational Features, Usage Scenarios, and Scenario Diagram

Functions: Provides positive shut-off and is ideal for frequent maintenance, cleaning, or seat replacement applications. Its design facilitates easy inline service.

Operational Features:

- Easy In-Line Maintenance: The valve can be serviced (seats replaced, ball cleaned) by simply unbolting the center section, without disturbing the pipe connections.

- Robust Construction: The bolted body design often provides a stronger, more reliable connection than a two-piece threaded body.

- Flexible End Configurations: End caps can be specified with different end connections (e.g., one end threaded, one end welded), offering flexibility.

- Bi-Directional Flow: Typically suitable for flow in either direction.

- Usage Scenarios: Preferred in applications where system uptime is critical and valves require periodic inspection or cleaning.

- Process & Chemical Lines: Where frequent cleaning or inspection for contamination is needed.

- Food & Beverage, Pharmaceutical: For hygienic processes requiring regular disassembly and cleaning (CIP/SIP).

- Frequent Maintenance Points: In systems where valve internals may wear or need replacement.

Instrumentation Manifolds.

3-Piece Threaded Ball Valve Standards: Materials, Design, and Connections

Material, Design, and Connection Standards

Material Standards:

- Body & End Caps: ASTM A105 (Forged Carbon Steel), A182 F316/304 (Stainless Steel), or Brass.

- Ball: 316 SS with chrome plating or solid 316 SS.

- Seats: PTFE, RPTFE, PEEK, UHMWPE, or Metal.

- Stem: 316 SS or 17-4PH.

- Bolts: ASTM A193 B7 or B8M.

- Design Standards: General industrial design based on API 6D principles and ASME B16.34 pressure-temperature ratings. Fire-safe designs per API 607/6FA are available.

Industrial valves Connection Standards:

- Thread Standards: Primarily ASME B1.20.1 (NPT). ISO 7-1 (BSPT) is also common.

- Pressure Ratings: Common ratings are Class 150, 300, and 600.

- Face-to-Face: Dimensions generally follow ASME B16.10.

How to Select 3-Piece Threaded Ball Valve

How to Purchase

Specify Requirements:

- Size, Pressure Class, and Material.

- Specify Seat Material (e.g., PTFE for general use, PEEK for high temp, Metal for fire-safe).

- Confirm thread standard (NPT or BSP).

- Consider if fire-safe certification or special cleaning/passivation (for stainless) is needed.

- Source from Specialized Suppliers: Choose manufacturers or distributors with a strong reputation for industrial process valves. They should provide detailed material traceability.

- Request Detailed Documentation: Ask for a datasheet with full material breakdown, pressure-temperature charts, and torque specifications for the body bolts.

- Evaluate and Order: Compare based on construction quality, material specs, and serviceability features. Ensure the purchase order specifies all critical materials and standards.

Pre-Shipment Inspection for Export 3-Piece Threaded Ball Valve and Key Considerations

Pre-Export Inspection and Precautions

Inspection Protocol:

- Visual & Dimensional Check: Inspect machining quality. Verify thread integrity on end caps.

- Material Verification: Request material certificates for body parts, ball, stem, and bolts, especially for stainless steel valves.

- Pressure Testing: Mandatory. Witness shell test and seat leakage test per API 598 or equivalent. Ensure testing is done in the fully assembled state.

- Disassembly & Reassembly Check (Key Feature): For a sample valve, perform a functional disassembly and reassembly. Verify that the center section separates and re-joins smoothly without misalignment, and that the body seals are in good condition.

- Function Test: Operate the valve to ensure smooth rotation and proper shut-off.

Precautions:

- Ship Fully Assembled & Closed: The valve should be shipped fully bolted together, with the ball in the closed position to protect the seats. Include a complete set of spare body seals/gaskets taped to the valve or placed in the accessory kit.

- Protect Threads & Sealing Faces: Use heavy-duty thread protectors on the end caps. The sealing faces between body sections must be free of damage.

- Secure Bolting: Ensure all body bolts are properly torqued before shipping. Include a note of the required torque value in the manual.

- Packaging: Use sturdy individual boxing. Clearly mark the box with handling instructions. For the center-section, immobilize the ball to prevent movement during transit.

- Documentation: Include test reports, material certificates, torque specifications, assembly diagrams, and the spare parts list in a waterproof pouch.

3-Piece Threaded Ball Valve Specification

| Nominal Pressure | PN | 1.6,2.5,4.0,6.4 |

MPa |

| Strengh testing pressure | PT | 2.4,3.8,6.0,9.6 | |

| Set testing pressure | 0.6 | ||

| Seat testing pressure | 2.0,3.0,4.8,7.6 | ||

| Applicable medium | Q11F-(16-64)C | Q11F-(16-64)P | Q11F-(16-64)R |

| Water, Oil, Steam | Nitric acid | Acetic acid | |

| Applicable Temperature | -40-180°C | ||

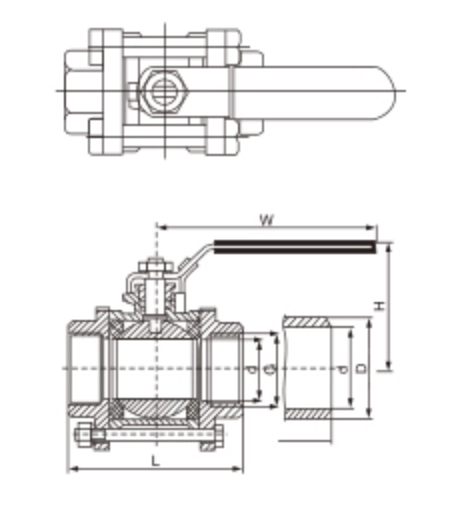

Main outer size Unit mm

| Spectification | 1/4” | 3/8” | 1/2” | 3/4” | 1” | 1 1/4” | 1 1/2” | 2” |

| Size | 6 | 10 | 15 | 20 | 25 | 32 | 40 | 50 |

| L | 65 | 44 | 55 | 60 | 72 | 77 | 88 | 100 |

| D | 11.6 | 7 | 9.2 | 12.5 | 16 | 20 | 24.5 | 32 |

| H | 44 | 36 | 41 | 44 | 48 | 54 | 65 | 72 |

| W | 100 | 73 | 86 | 86 | 103 | 103 | 140 | 140 |

We also supply fire valve and water valves.

.png)

.png)