Grooved Resilient Seated NRS Gate Valve No. Z85X

Grooved Resilient Seated NRS Gate Valve Definition and Components

Fire gate valve Definition & Main Parts

A Grooved Resilient Seated NRS Gate Valve Model No. Z85X is a valve designed for use with grooved piping systems. It uses a mechanical grooved coupling connection instead of flanges or threads, allowing for quick installation and disassembly. The "Z85X" designation indicates: Z=Gate valve, 85=Grooved ends, X=Resilient seated.

Gate Valve NRS Main Parts:

- Valve body with integral grooved ends

- Resilient-seated gate

- Non-rising stem assembly

- Handwheel or gear operator

- Groove for coupling housing

- Rubber sealing gasket (for grooved connection)

Role, Characteristics, and Application Scenarios of Grooved Resilient Seated NRS Gate Valve in Pipelines

Functions:

- Quick isolation in grooved piping systems

- Fire protection system control

- Industrial process line shutdown

- HVAC and plumbing system valves

Operational Features:

- Quick installation - uses grooved couplings

- No welding/threading required

- Compact design - shorter face-to-face than flanged

- Easy maintenance - can be removed without pipe cutting

- Bubble-tight seal - resilient seated design

Typical Applications:

- Fire sprinkler systems

- Industrial process water lines

- HVAC chilled/heating water

- Temporary piping systems

- Mining and marine applications

Scenario Diagram:

Grooved Resilient Seated NRS Gate Valve Standards: Materials, Design, and Connections

Material Standards:

- Body: Ductile Iron ASTM A536 or Cast Iron ASTM A126

- Stem: Stainless Steel ASTM A276

- Gate: Ductile Iron with EPDM encapsulation

- Seats: EPDM (standard), Viton (chemical service)

Design Standards:

- UL/FM Standards for fire protection (UL 262, FM 1120)

- AWWA C509 for waterworks (some models)

- MSS SP-68 for high pressure grooved connections

- Pressure ratings: 175 psi, 200 psi, 300 psi common

Connection Standards:

- Groove Standard: ANSI/AWWA C606 (groove dimensions)

- Coupling Compatibility: Designed for standard grooved couplings

- Gasket Type: EPDM/CIIR for fire protection, various for other services

- End Types: Grooved x Grooved (both ends)

How to Select Grooved Resilient Seated NRS Gate Valve

Key Steps:

- Specify Requirements: Size, pressure class, service (fire, water, chemical)

- Verify Standards: UL/FM listing for fire protection, other certs as needed

- Select Supplier: Manufacturers specializing in grooved products

- Order Components: Include required couplings and gaskets

- Review Documentation: Request product listings and installation guides

Critical Specifications:

- Service type (fire protection, HVAC, industrial)

- Pressure rating required

- Temperature range

- Connection size (groove dimensions)

- Required certifications (UL, FM, NSF)

Important Considerations:

- Purchase matching couplings and gaskets

- Verify groove tooling compatibility

- Check installation torque requirements

- Consider future maintenance access

Pre-Shipment Inspection for Export Grooved Resilient Seated NRS Gate Valve and Key Considerations

Documentation Check:

- UL/FM Listing Certificates (for fire service)

- Material Certificates

- Pressure Test Certificates

- Installation Instructions

Physical Inspection:

Groove Dimension Check

Verify groove width and depth

Check groove smoothness and edges

Measure outside diameter at grooves

Pressure Testing

Hydrostatic shell test: 1.5× rated pressure

Seat leakage test: 1.1× rated pressure

Fire test certification if applicable

Operational Test

Smooth handwheel operation

Proper stem packing adjustment

Clear open/close indication

Surface & Coating

Red epoxy coating for fire protection

Proper identification markings

No damage to groove surfaces

Export Packaging:

- Groove protection - plastic or cardboard sleeves

- Thread protection - caps on stem threads

- Separate packaging for coupling kits

- Moisture protection for long sea voyages

- Clear labeling of valve orientation

Key Precautions:

- Groove protection: Critical - damage affects sealing

- Certification documents: Must accompany fire protection valves

- Gasket compatibility: Include correct gaskets for service

- Installation tools: Consider including groove measurement tools

- Climate control: For rubber components in extreme climates

Fire valve Final Documents:

- Commercial Invoice

- Packing List

- Bill of Lading

- Certification Folder (UL/FM/NSF)

- Material Test Reports

- Installation/Maintenance Manual

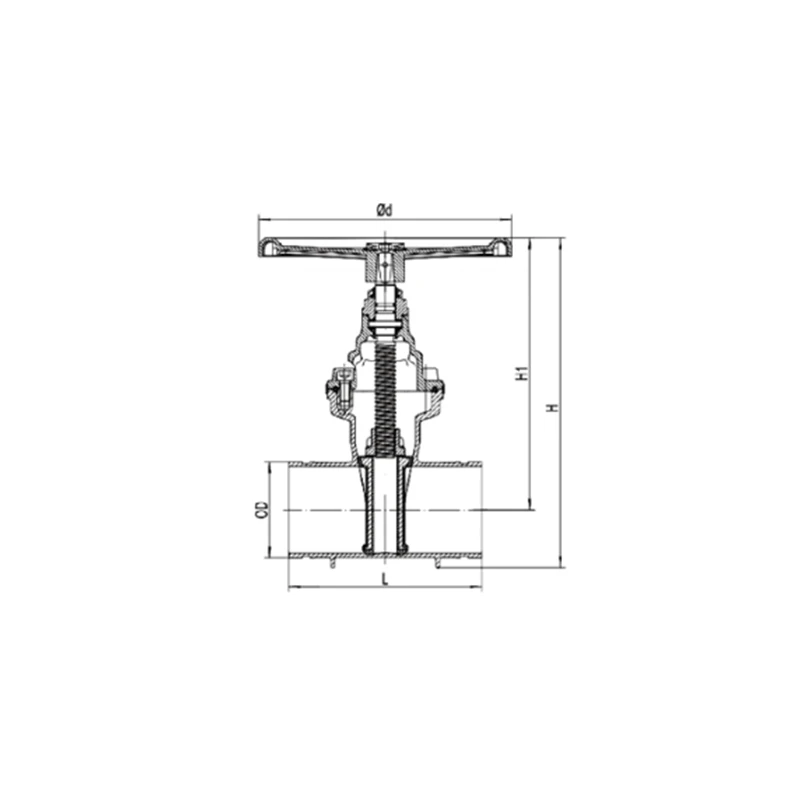

Grooved Resilient Seated NRS Gate Valve Size Chart

| Dimensions | Pressure rating | Size(mm) | |||||

| DN | inch | Psi | Ф D | L | H1 | H | Ф d |

| 50 | 2 | 362 | 60.3 | 178 | 256 | 301 | 203 |

| 65 | 2.5 | 362 | 73 | 190 | 256 | 307.5 | 203 |

| 76.1 | 309 | ||||||

| 80 | 3 | 362 | 88.9 | 203 | 273.5 | 333 | 203 |

| 100 | 4 | 362 | 114.3 | 229

|

323.5 | 396 | 300 |

| 125 | 5 | 362 | 139.7 | 254 | 376 | 461 | 300 |

| 141.3 | 462 | ||||||

| 150 | 6 | 362 | 165.1 | 267

|

423.5 | 521 | 300 |

| 168.3 | 523 | ||||||

| 200 | 8 | 362 | 219.1 | 292 | 530.5 | 660 | 406 |

.png)

.png)