DIN F4 Flanged Resilient Seated OS&Y Gate Valve

DIN F4 Flanged Resilient Seated OS&Y Gate Valve Definition and Components

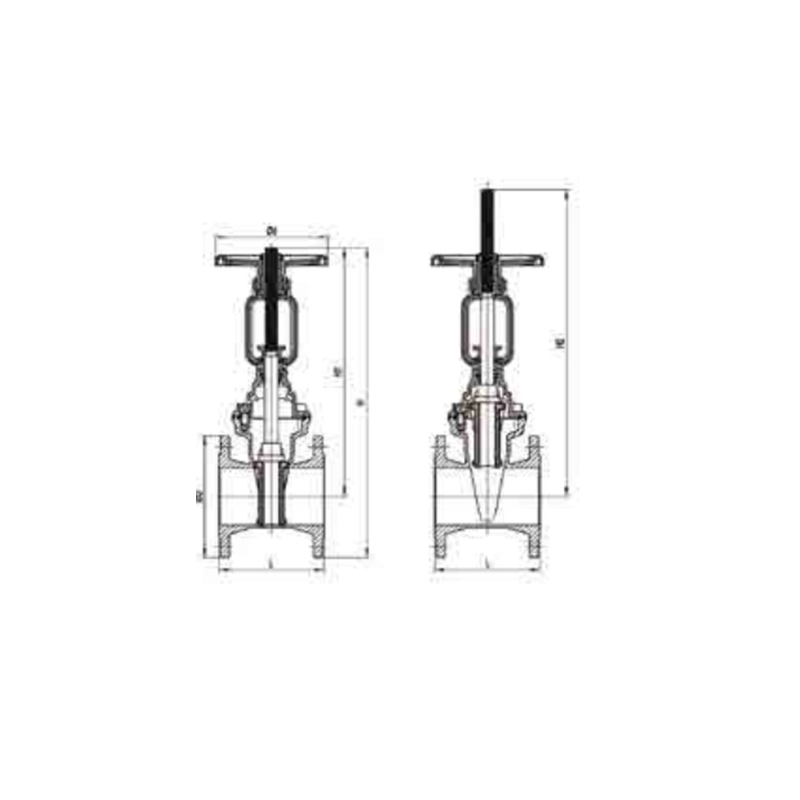

Definition & Main Parts

A DIN F4 Flanged Resilient Seated OS&Y Gate Valve Model No. Z41X-01 is a valve designed to European standards featuring an Outside Screw and Yoke (OS&Y) stem design and DIN F4 flanged connections. The model number decodes as: Z=Gate valve, 41=Flanged OS&Y, X=Resilient seat, 01=Design variant/Pressure class.

Flanged OS&Y Gate Valve Main Parts:

- Valve body with DIN F4 flanges (grooved face with concentric serrations)

- Resilient-seated gate

- OS&Y (Outside Screw & Yoke) assembly: Yoke, rising stem, exposed threads

- Handwheel mounted on yoke

- Gland packing system (visible and adjustable)

- Body-bonnet gasket and flange gaskets

Role, Characteristics, and Application Scenarios of DIN F4 Flanged Resilient Seated OS&Y Gate Valve in Pipelines

Functions:

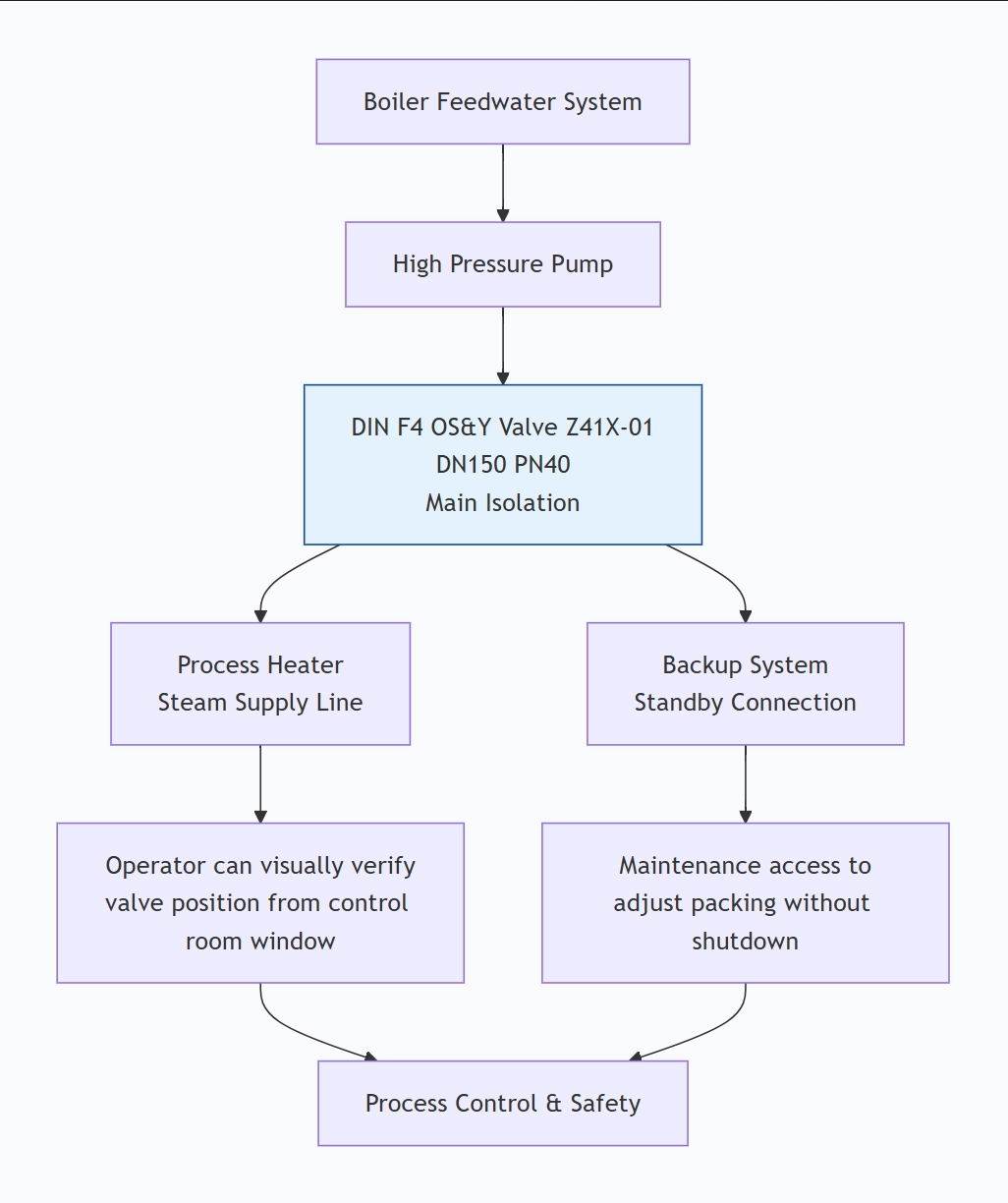

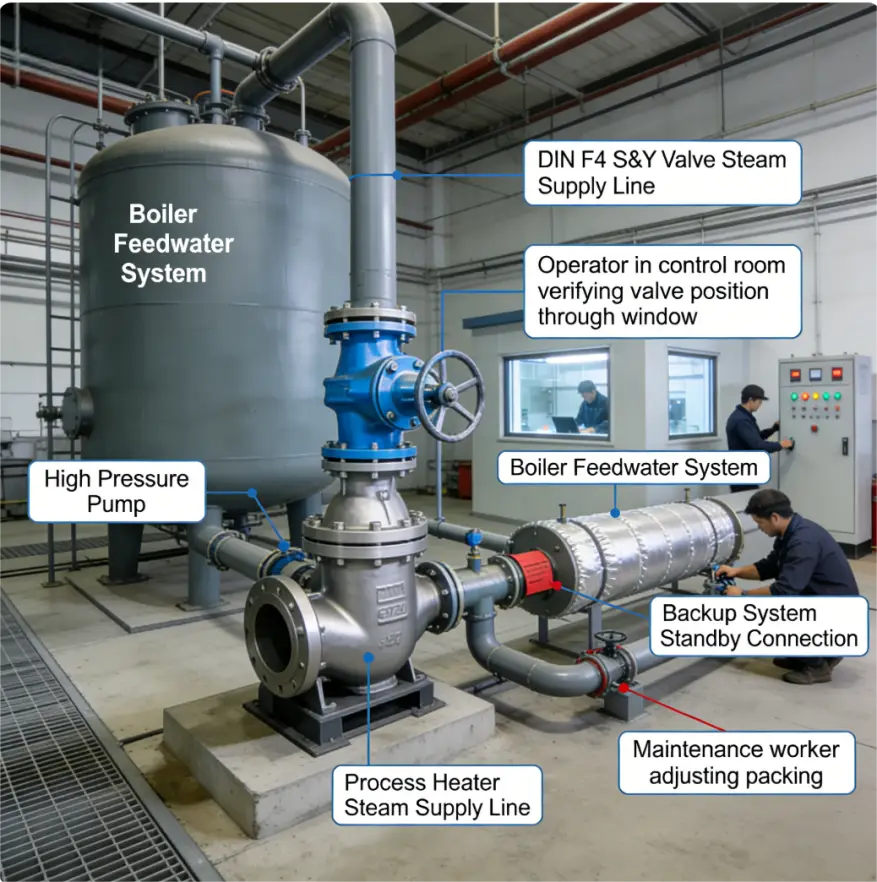

- Mainline isolation in industrial and water systems

- Visual stem position indication (open/closed)

- High-pressure/high-temperature applications

- Critical service where valve status must be visible

Operational Features:

- OS&Y Design: Stem rises visibly when opening, providing clear position indication

- Easy Maintenance: Packing can be adjusted or replaced while valve is under pressure

- DIN F4 Flanges: Grooved face ensures excellent gasket grip

- Resilient Seat: Provides bubble-tight seal

- High Durability: Suitable for frequent operation

Typical Applications:

- Industrial process plants

- Power generation facilities

- Chemical processing lines

- High-pressure water systems

- Steam applications (with appropriate trim)

Scenario Diagram:

DIN F4 Flanged Resilient Seated OS&Y Gate Valve Standards: Materials, Design, and Connections

Fire valve Material Standards:

- Body/Bonnet: Ductile Iron EN-GJS-500-7 or Carbon Steel

- Stem: Stainless Steel 1.4057 (AISI 416 equivalent)

- Gate: Ductile Iron with EPDM encapsulation

- Yoke/Bolting: Carbon steel with protective coating

Design Standards:

- DIN EN 1171: Industrial valves - Cast iron gate valves (primary)

- DIN EN 12266-1: Pressure testing of valves

- ISO 5208: Industrial valve pressure testing

- Pressure ratings: PN10, PN16, PN25, PN40 available

Connection Standards:

- Flanges: DIN EN 1092-2 Type F4 (grooved face with concentric serrations)

- Face-to-Face: DIN 3202 series dimensions

- Pressure Classes: PN10 through PN40 as per DIN 2501

- Gaskets: Full-face type matching F4 groove pattern

How to Select DIN F4 Flanged Resilient Seated OS&Y Gate Valve

Fire gate valve Key Steps:

- Specify Requirements: Size, pressure class, material specifications

- Verify Standards Compliance: Must meet DIN EN 1171 and DIN EN 1092-2 F4

- Select Supplier: European manufacturers or certified international producers

- Review Documentation: Request EN 10204 3.1 material certificates

- Consider Options: Special trims for high temperature or corrosive service

Critical Specifications:

- Pressure rating (PN16, PN25, PN40 most common)

- Temperature range for seat material

- Stem packing material (graphite, PTFE, etc.)

- Yoke design (single piece, bolted)

- Actuator mounting provisions (ISO 5211)

Important Considerations:

- Verify F4 flange machining quality

- Check compatibility with existing gaskets

- Consider stem protection for corrosive environments

- Review maintenance requirements for OS&Y design

Pre-Shipment Inspection for Export DIN F4 Flanged Resilient Seated OS&Y Gate Valve and Key Considerations

Documentation Check:

- EN 10204 3.1 Material Certificates

- DIN EN 1171 compliance statement

- Pressure test certificates (DIN EN 12266-1)

- CE marking documentation (if applicable)

- Potable water approval certificates (if required)

Physical Inspection:

OS&Y Mechanism Inspection

Smooth stem operation through full travel

Visible rising stem function

Yoke integrity and alignment

Thread protection on exposed stem

DIN F4 Flange Verification

F4 groove pattern (concentric serrations)

Flange thickness and drilling dimensions

Surface finish quality

No damage to serrated face

Pressure Testing

Shell test: 1.5 × PN pressure

Seat test: 1.1 × PN pressure (both directions)

Backseat test (if applicable)

Packing leakage check

Visual & Dimensional

Clear position indication markings

Proper painting/coating

Complete assembly (all bolts, nuts)

Face-to-face dimensions per DIN 3202

Export Packaging:

- F4 flange protectors: Bolt-on rigid covers mandatory

- Stem protection: Thread protectors on exposed stem threads

- Yoke protection: Prevent damage during handling

- VCI protection: Internal cavity protection for sea transport

- Wooden crating: Heavy-duty for larger valves

- Orientation markings: "This side up" for OS&Y valves

Key Precautions:

- F4 face protection: Critical - serrations easily damaged

- Stem alignment: Ensure stem is not bent during packaging

- Corrosion protection: Extra VCI for marine environments

- Documentation completeness: All DIN/EN certificates must be included

- Lifting points: Clearly mark proper lifting locations (never lift by handwheel)

Final Shipping Documents:

- Commercial Invoice with detailed description

- Packing List with valve serial numbers

- Bill of Lading

- Certificate of Origin

- Technical file (material certs, test reports, compliance statements)

- Installation and Maintenance Manual

DIN F4 Flanged Resilient Seated OS&Y Gate Valve Size Chart

.png)

.png)