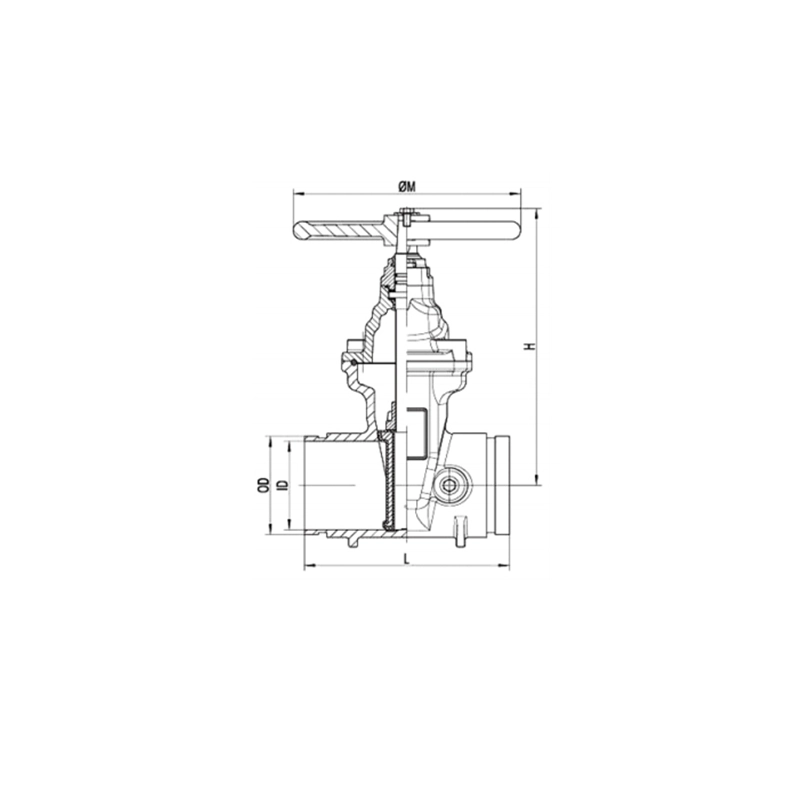

Grooved Resilient Seated NRS Gate Valve Model No. 1111

Grooved Resilient Seated NRS Gate Valve Model No. 1111 Definition and Components

Definition & Main Parts

A Grooved Resilient Seated NRS Gate Valves Model No. 1111 is a valve specifically designed for fire protection systems using grooved piping connections. The "1111" model number typically indicates it's a fire protection specific valve (often UL/FM approved) with grooved ends.

Main Parts:

- Valve body with precision grooved ends

- Resilient-seated gate (fire-rated design)

- Non-rising stem assembly

- Handwheel with chainwheel option

- UL-listed components throughout

- Factory-applied red epoxy coating

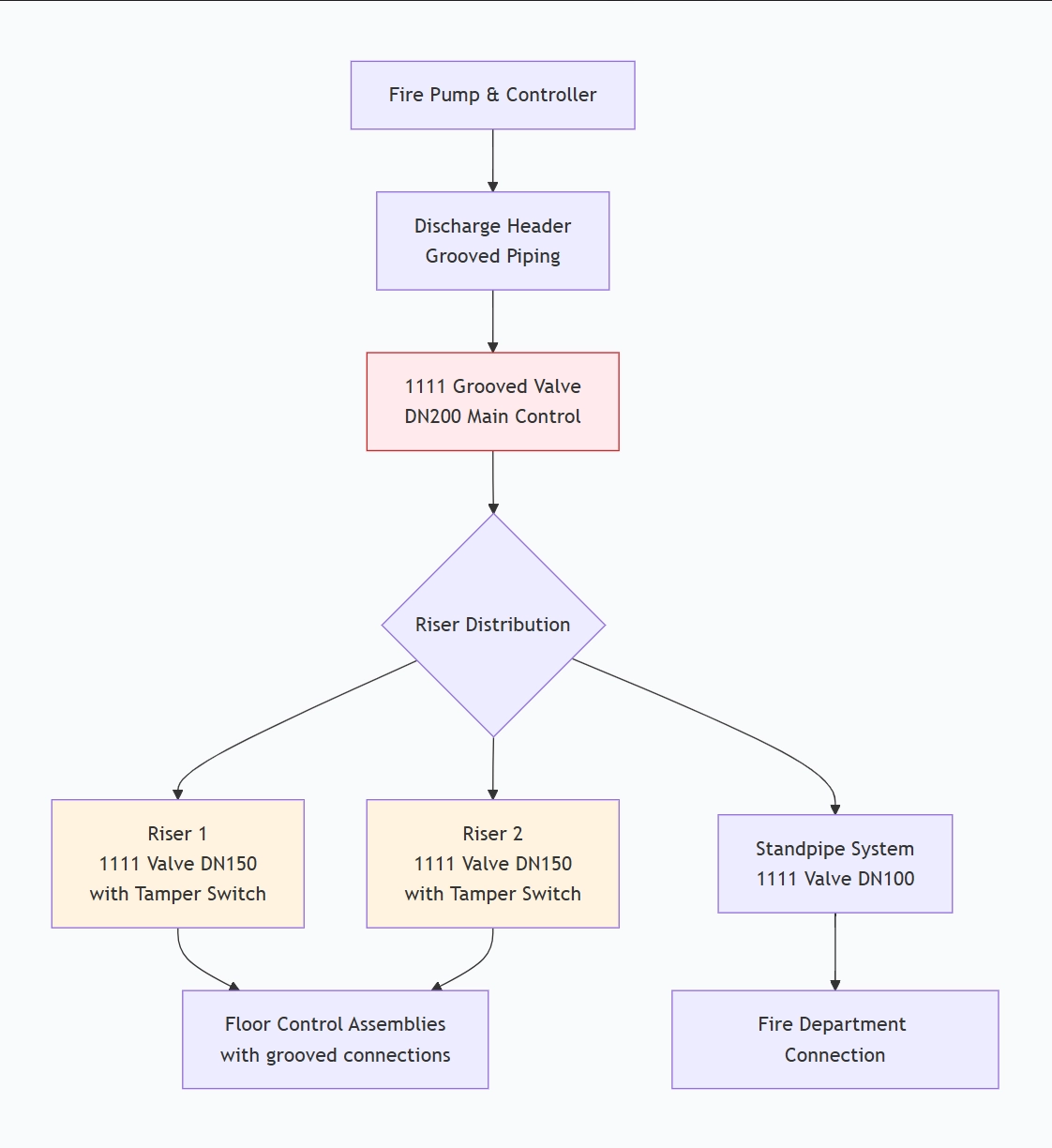

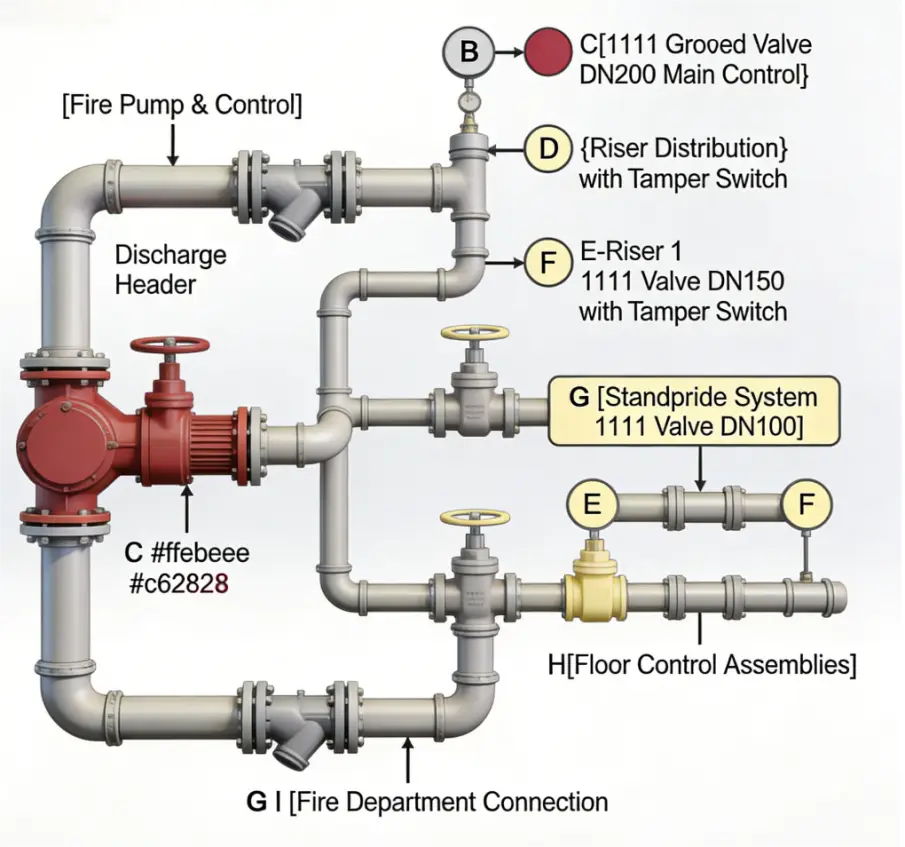

Role, Characteristics, and Application Scenarios of Grooved Resilient Seated NRS Gate Valve Model No. 1111 in Pipelines

Functions:

- Main control valve in fire sprinkler systems

- Sectional isolation in fire protection piping

- Pump discharge/suction valve

- Riser control valve

Operational Features:

- Quick installation with grooved couplings

- UL/FM listed for fire protection service

- Tamper indication provision (for supervisory switches)

- Easy maintenance without pipe cutting

- Supervisory switch mounting capability

Typical Applications:

- Wet pipe sprinkler systems

- Dry pipe valve supply lines

- Fire pump discharge piping

- High-rise building risers

- Industrial fire protection

Scenario Diagram:

Grooved Resilient Seated NRS Gate Valve Model No. 1111 Standards: Materials, Design, and Connections

Material Standards:

- Body: Ductile Iron ASTM A536 Grade 65-45-12

- Stem: Stainless Steel ASTM A276 Type 416

- Gate: Bronze or ductile iron with EPDM

- Coating: Red epoxy (5-8 mils thickness)

Design Standards:

- UL 262 - Standard for Gate Valves for Fire-Protection Service

- FM 1120 - Approval Standard for Valves

- NFPA 13/14/20 - Installation standards compliance

- Pressure rating: 175 psi (standard), 300 psi (high pressure)

Connection Standards:

- Groove Standard: Per manufacturer (Victaulic, Gruvlok, etc.) or ANSI/AWWA C606

- End Types: Grooved x Grooved

- Gaskets: EPDM for standard, CIIR for chemical resistance

- Couplings: Must match groove profile (1-groove, 2-groove styles)

How to Select Grooved Resilient Seated NRS Gate Valve Model No. 1111

Key Steps:

- Verify Requirements: UL listing mandatory, FM approval often required

- Specify Details: Size, pressure class, supervisory switch provisions

- Choose Supplier: UL-listed manufacturers with proven track record

- Order Complete Assembly: Include couplings, gaskets, switches as needed

- Review Certifications: UL/FM labels must be physically on valve

Critical Specifications:

- UL listing number

- FM approval number (if required)

- Groove style compatibility

- Pressure rating (175 psi minimum for sprinklers)

- Tamper switch mounting provisions

Important Notes:

- Purchase from authorized fire protection distributors

- Ensure valve has permanent UL/FM marking

- Consider factory-assembled switch packages

- Verify compatibility with existing grooved systems

Pre-Shipment Inspection for Export Grooved Resilient Seated NRS Gate Valve Model No. 1111 and Key Considerations

Documentation Check:

- UL Listing Certificate copy

- FM Approval Certificate (if applicable)

- Material Certificates (ASTM compliance)

- Factory test reports

- Installation instructions

Physical Inspection:

UL/FM Markings Verification

Permanent marking on valve body

Correct model number

Pressure rating clearly shown

Groove Inspection

Precision groove dimensions

Smooth, undamaged groove surfaces

Proper outside diameter

Pressure Testing

Shell test: 2 × rated pressure (350 psi for 175 psi valve)

Seat test: 1.1 × rated pressure (193 psi for 175 psi valve)

Zero leakage requirement

Fire Protection Specific Checks

Red epoxy coating (complete coverage)

Tamper switch mounting pads/lugs

Handwheel or chainwheel operation

Clear open/close indication

Export Packaging:

- Individual boxing for each valve

- Groove protectors (rigid plastic)

- Desiccant packs in valve cavity

- Separate package for switches/accessories

- Climate-controlled if rubber components included

- UL labels protected from damage

Fire gate valve Key Precautions:

- Certification integrity: UL/FM labels must remain visible

- Rubber components: Protect from ozone/UV exposure

- Documentation: Include compliance certificates in shipment

- Installation parts: Package gaskets separately with part numbers

- Climate considerations: Special packaging for tropical/humid destinations

Fire valve Final Shipping Package:

- Commercial documents (invoice, packing list, B/L)

- Technical folder (certificates, test reports, manuals)

- Valve in protective packaging

- Accessories in labeled separate boxes

- Installation templates/tools if specified

Grooved Resilient Seated NRS Gate Valve Model No. 1111 Size Chart

.png)

.png)