Grooved Resilient Seated OS&Y Gate Valve Model No. 1211

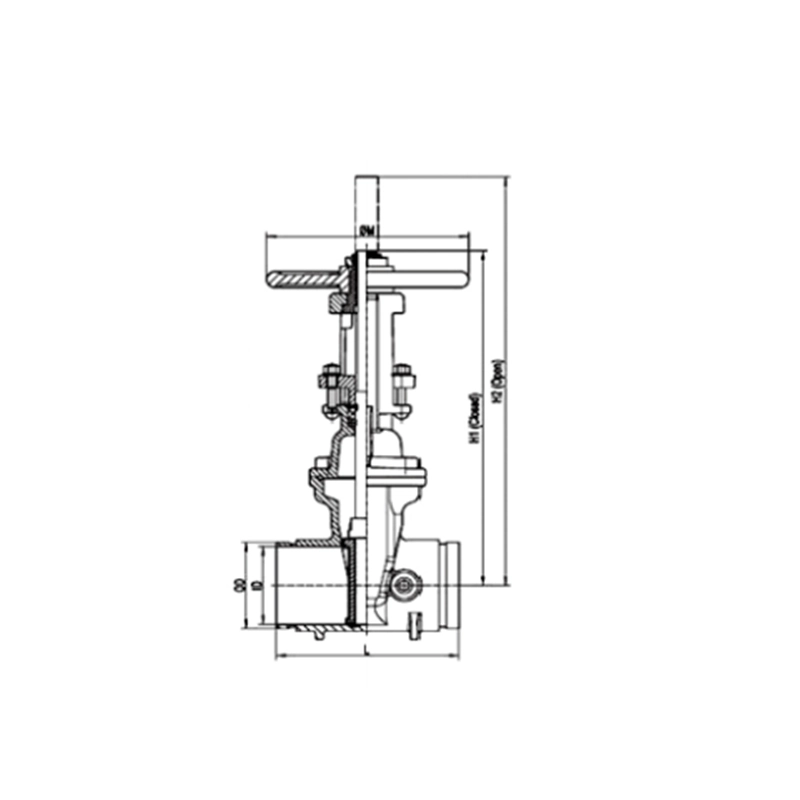

Grooved Resilient Seated OS&Y Gate Valve Model No. 1211 Definition and Components

Grooved OS&Y Gate Valves Definition & Main Parts

A Grooved Resilient Seated OS&Y Gate Valve Model No. 1211 is a fire protection or industrial valve combining grooved pipe connections with OS&Y (Outside Screw and Yoke) visible stem design. This allows for both quick installation and visual position verification.

Main Parts:

- Valve body with grooved ends

- Resilient-seated gate

- OS&Y assembly with visible rising stem

- Yoke and handwheel

- Adjustable gland packing

- Groove profiles for coupling connection

- Standard red coating for fire protection

Role, Characteristics, and Application Scenarios of Grooved Resilient Seated OS&Y Gate Valve Model No. 1211 in Pipelines

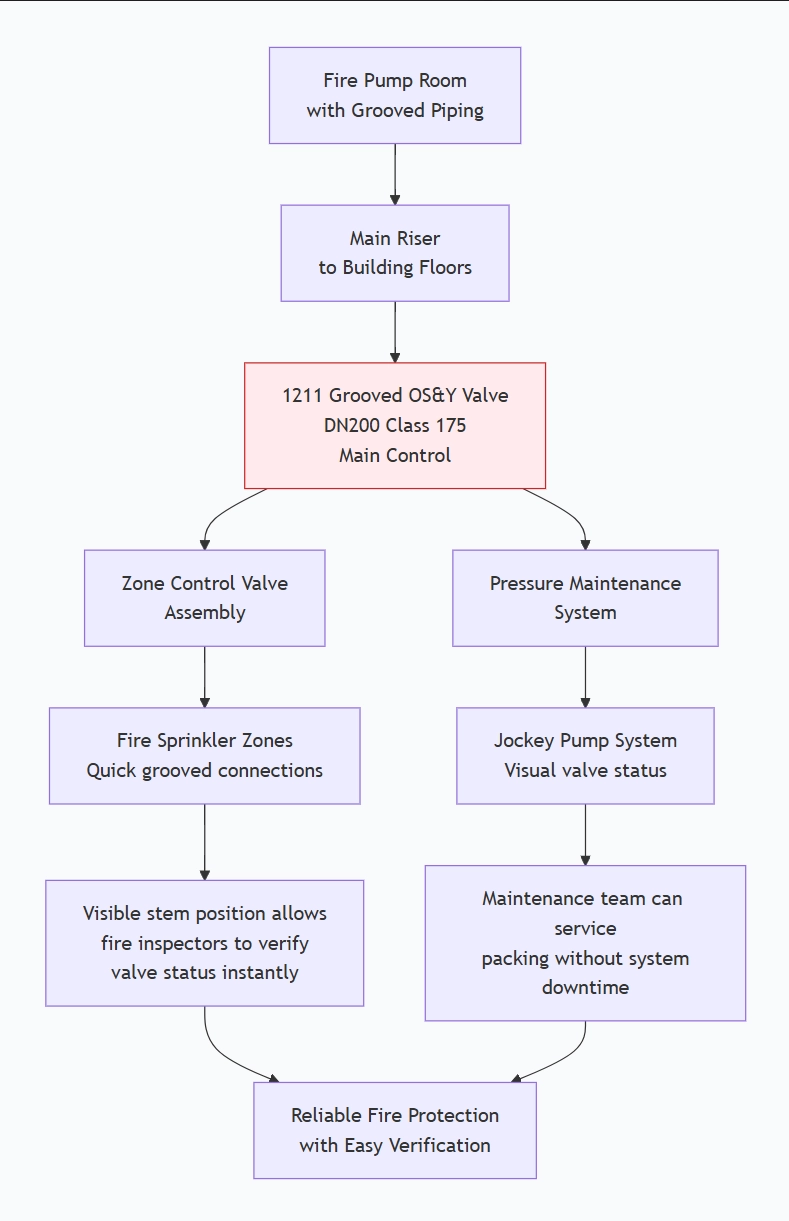

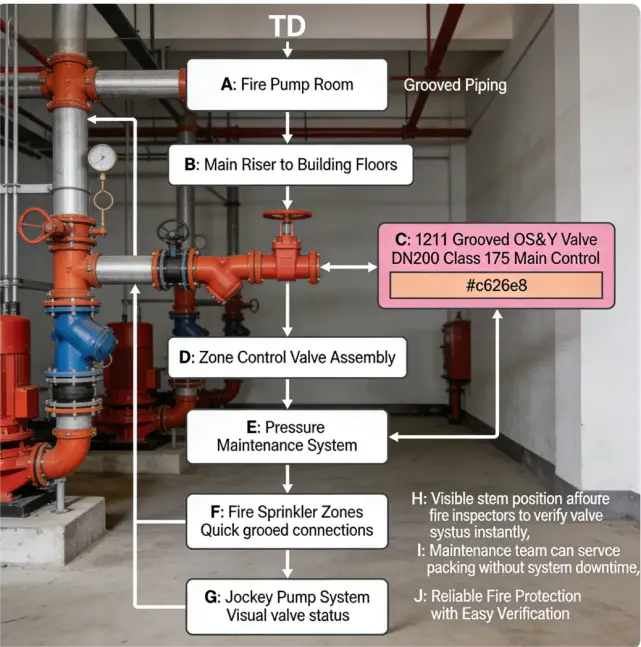

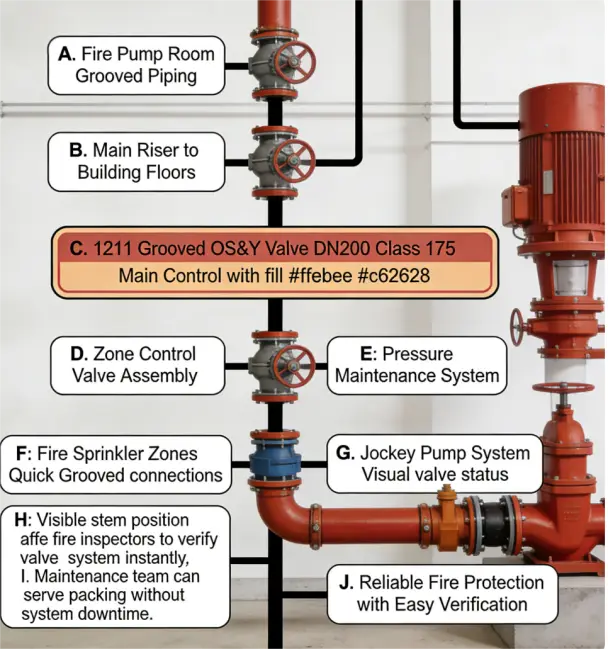

Fire valve Functions:

- Main isolation in grooved fire protection systems

- Critical shutdown points with position visibility

- Pump control in industrial systems

- High-reliability valves in quick-install systems

Operational Features:

- Quick installation via grooved couplings

- Visual position indication from rising stem

- Easy maintenance-packing adjustable in place

- UL/FM listed for fire protection service

- Space efficient compared to flanged OS&Y valves

Typical Applications:

- Fire sprinkler system risers

- Industrial fire protection lines

- Process water systems with grooved piping

- Pump discharge/suction in quick-install systems

- High-rise building fire protection

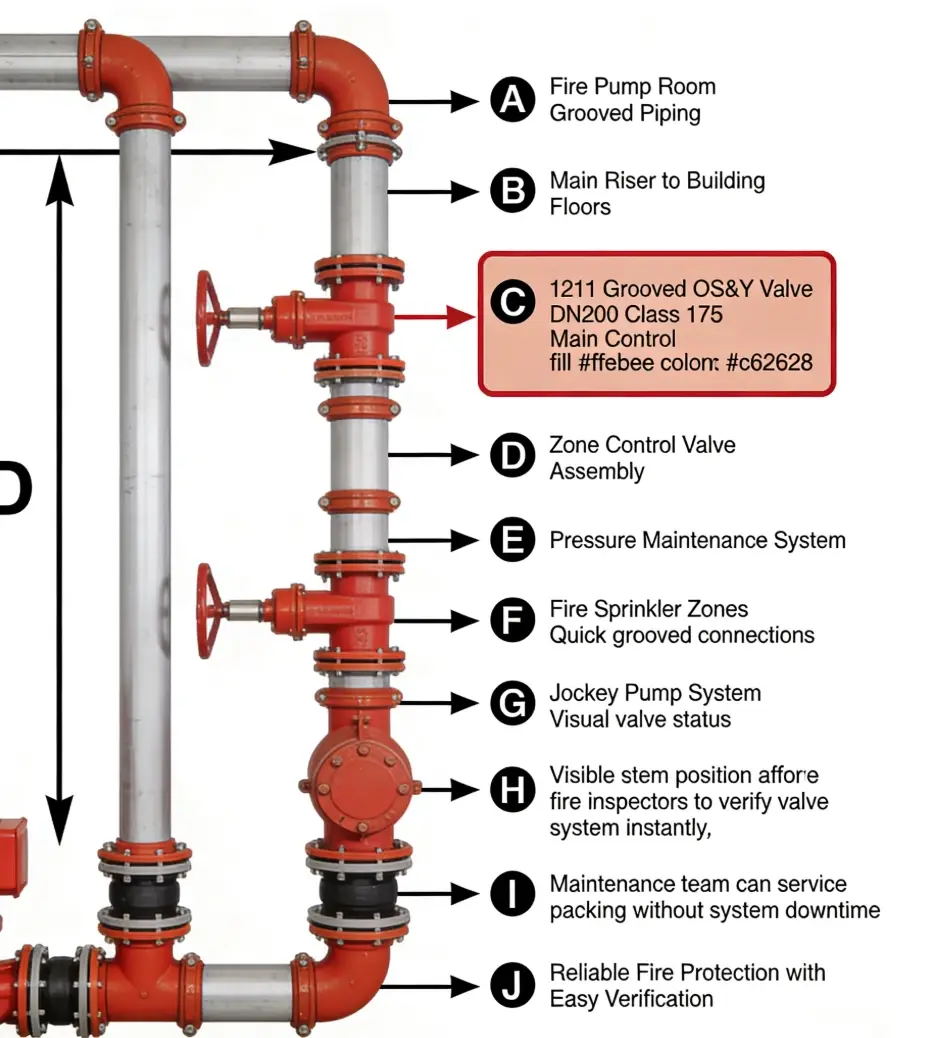

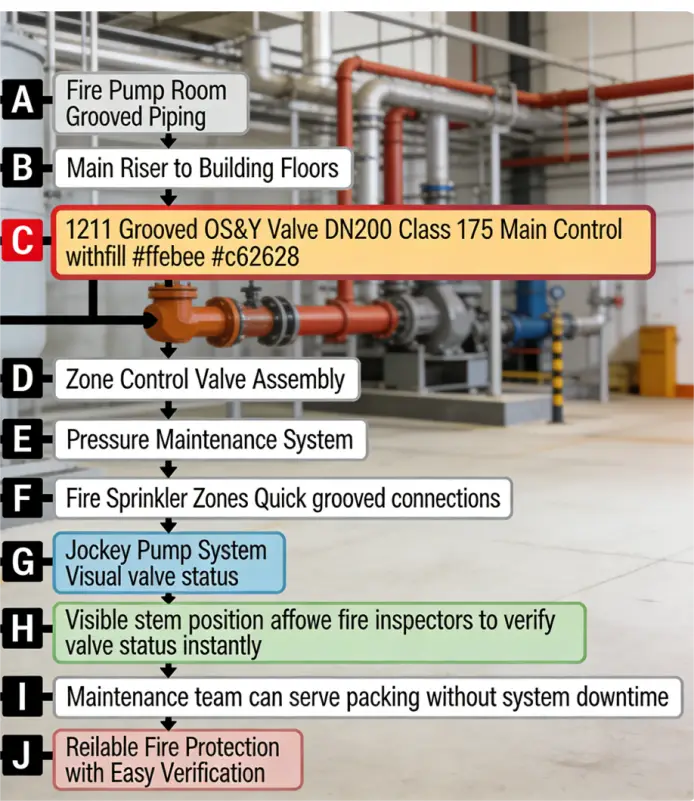

Scenario Diagram:

Grooved Resilient Seated OS&Y Gate Valve Model No. 1211 Standards: Materials, Design, and Connections

Fire gate valve Material Standards:

- Body/Bonnet:Ductile Iron ASTM A536

- Stem:Stainless Steel AISI 416

- Gate:Ductile iron with EPDM encapsulation

- Yoke:Cast iron or ductile iron

- Coating:Red epoxy for fire protection

Design Standards:

- UL 262-Gate Valves for Fire Protection Service

- FM 1120-Approval Standard for Valves

- NFPA 13/14-Installation compliance

- Pressure ratings:175 psi,200 psi,300 psi

Connection Standards:

- Groove Standard:Per manufacturer(Victaulic,Gruvlok,etc.)

- Groove Dimensions:ANSI/AWWA C606 compliant

- Gaskets:EPDM for standard,CIIR for chemical resistance

- Couplings:Must match specific groove style

How to Select Grooved Resilient Seated OS&Y Gate Valve Model No. 1211

Key Steps:

- Confirm Application: Fire protection or industrial service

- Verify Listings: UL/FM mandatory for fire protection

- Specify Groove Type: Must match existing system couplings

- Select Supplier: Manufacturer with grooved valve expertise

- Order Components: Include matching couplings and gaskets

Critical Specifications:

- UL listing number for fire service

- Groove style compatibility (specific brand/model)

- Pressure rating (175 psi minimum for sprinklers)

- Position indicator requirements

- Tamper switch provisions

Important Considerations:

- Verify groove compatibility with existing system

- Purchase couplings and gaskets from same supplier

- Consider installation tools availability

- Check maintenance space around OS&Y mechanism

Pre-Shipment Inspection for Export Grooved Resilient Seated OS&Y Gate Valve Model No. 1211 and Key Considerations

Documentation Check:

- UL Listing Certificate

- FM Approval Certificate(if applicable)

- Material Test Reports

- Pressure Test Certificates

- Groove Dimension Certification

Physical Inspection:

OS&Y Mechanism Verification

Smooth rising stem operation

Full visible travel from closed to open

Yoke and stem alignment

Thread condition on exposed stem

Groove Quality Inspection

Precise groove dimensions

Smooth groove surfaces

Proper outside diameter

No damage to groove edges

Fire Protection Specific Checks

Red epoxy coating(complete coverage)

UL/FM permanent markings

Tamper switch mounting provisions

Proper handwheel operation

Pressure Testing

Shell test:2×rated pressure

Seat test:1.1×rated pressure

Zero leakage requirement

Packing leakage check

Export Packaging:

- Groove protectors:Rigid plastic sleeves mandatory

- Stem protection:Thread protectors for exposed stem

- Separate packaging:For couplings and accessories

- VCI protection:For internal cavity during sea transport

- Color coding:Clearly mark as fire protection valve

- Document pouch:Waterproof for certificates

Key Precautions:

- Groove protection:Critical-damage prevents coupling fit

- UL/FM labels:Must remain visible and intact

- Long stems:Protect from bending during handling

- Rubber components:Protect from ozone and UV exposure

- Climate control:For destinations with extreme conditions

Final Shipping Documents:

- Commercial Invoice

- Packing List with valve and accessory details

- Bill of Lading

- Certificate of Origin

- Technical File(UL/FM certificates,test reports)

- Groove Compatibility Documentation

- Installation&Maintenance Manual

Grooved Resilient Seated OS&Y Gate Valve Model No. 1211 Size Chart

.png)

.png)