Grooved Resilient Seated OS&Y Gate Valve Model No. Z81X

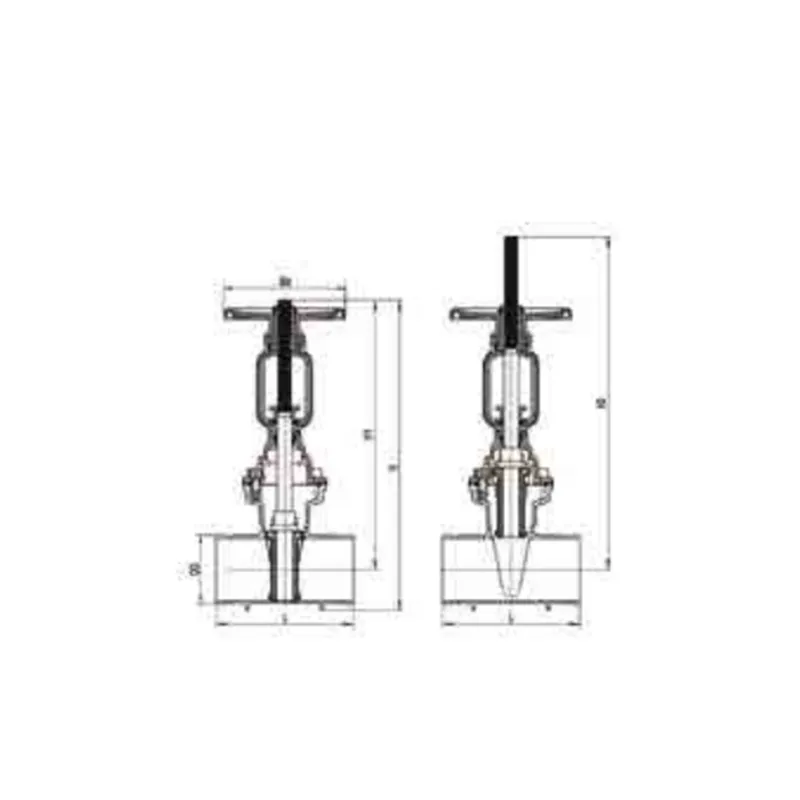

Grooved Resilient Seated OS&Y Gate Valve Model No. Z81X Definition and Components

OS&Y Gate Valve Grooved Definition&Main Parts

A Grooved Resilient Seated OS&Y Gate Valve Model No.Z81X is an industrial valve designed for grooved piping systems with a visible rising stem(Outside Screw and Yoke design).The"Z81X"designation indicates:Z=Gate valve,8=Grooved ends,1=OS&Y design,X=Resilient seat.

Fire gate valve Main Parts:

- Valve body with precision grooved ends

- Resilient-seated gate

- OS&Y assembly with yoke and visible rising stem

- Handwheel mounted on yoke

- Adjustable gland packing system

- Groove profiles for mechanical couplings

- Industrial coating(gray or specified color)

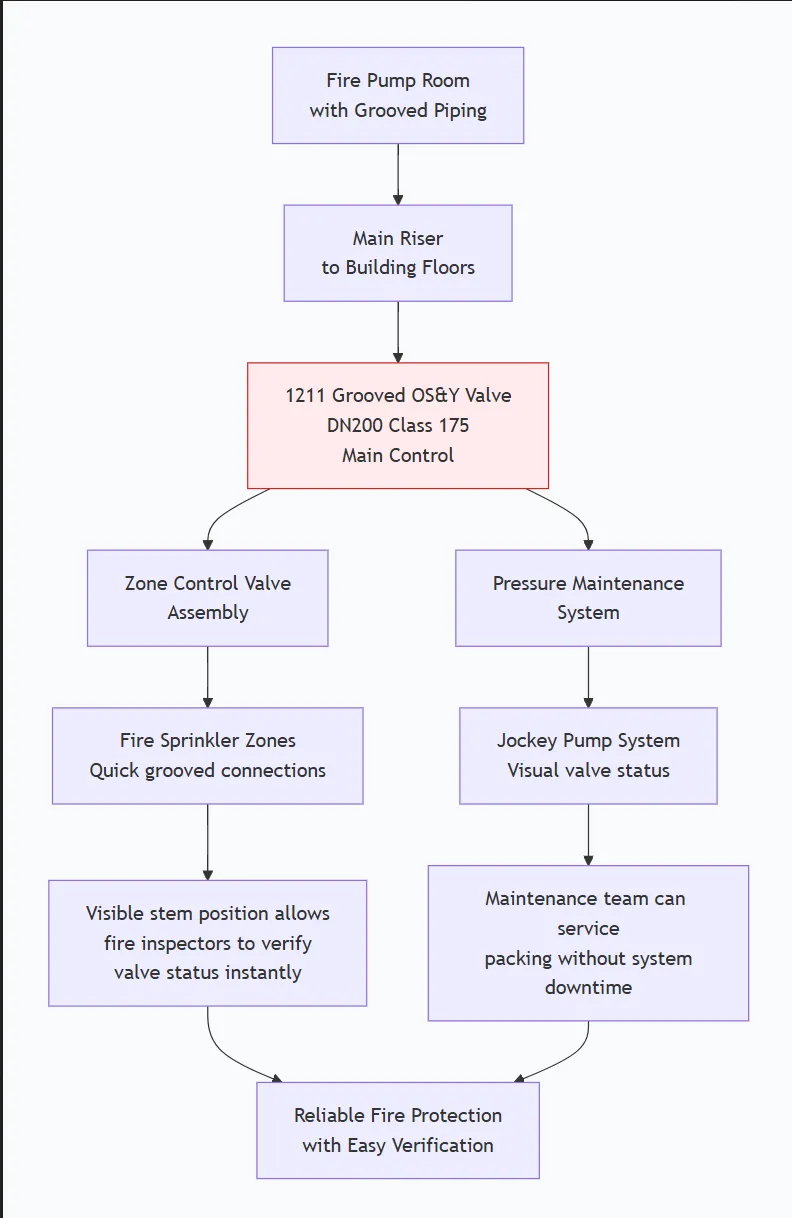

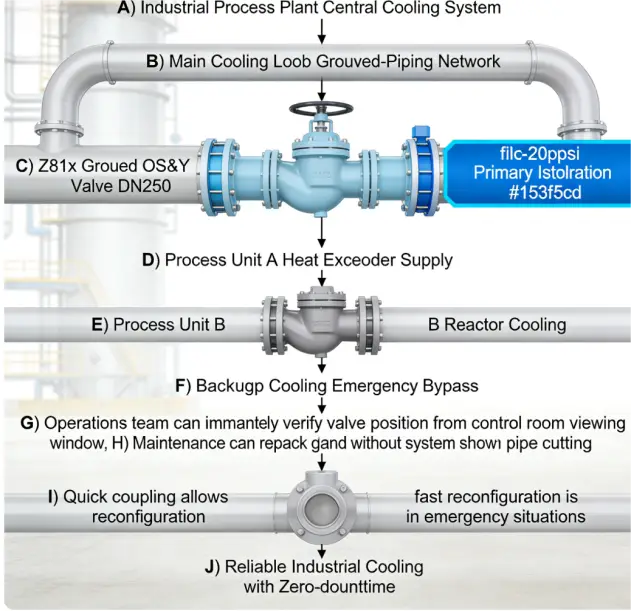

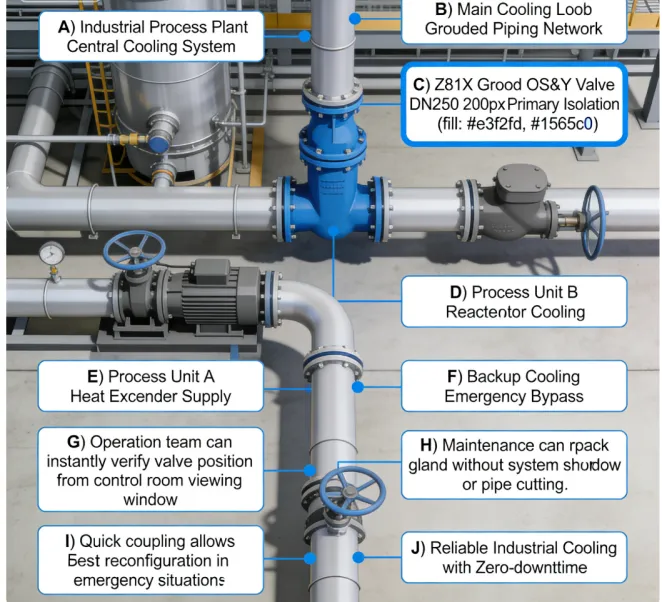

Role, Characteristics, and Application Scenarios of Grooved Resilient Seated OS&Y Gate Valve Model No. Z81Xin Pipelines

Fire valve Functions:

- Main isolation in industrial grooved piping systems

- Critical process shutdown with visual verification

- Pump control in quick-install systems

- High-reliability valves where position must be visible

Operational Features:

- Quick installation/removal via grooved couplings

- Visual position indication from rising stem

- Maintainable packing while valve is in service

- Industrial grade construction for tough service

- Full port design for minimal pressure drop

Typical Applications:

- Industrial process water systems

- Chemical processing plants (with compatible materials)

- Cooling water distribution

- Mining and mineral processing

- Marine and offshore installations

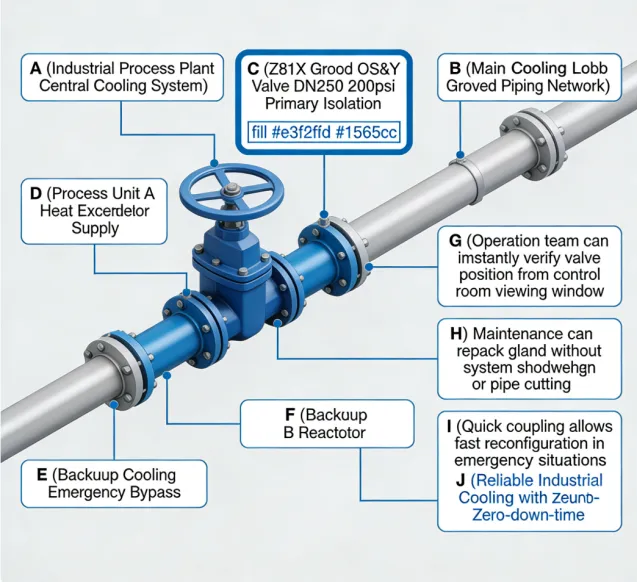

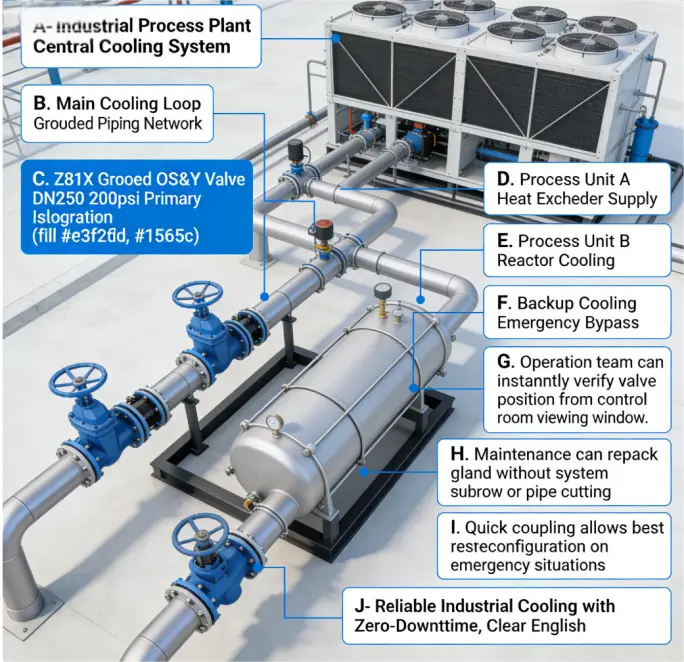

Scenario Diagram:

Grooved Resilient Seated OS&Y Gate Valve Model No. Z81X Standards: Materials, Design, and Connections

Material Standards:

- Body/Bonnet: Ductile Iron ASTM A536 or Carbon Steel A216 WCB

- Stem: Stainless Steel AISI 410/416 or AISI 304/316

- Gate: Ductile iron or steel with EPDM encapsulation

- Yoke: Cast steel or ductile iron

- Packing: Graphite or braided for industrial service

Design Standards:

- MSS SP-68: High Pressure Grooved Connections

- API 600 (if carbon steel construction)

- ISO 10434: Bolted bonnet steel gate valves

- ANSI/AWWA C606: Grooved and shouldered joints

- Pressure classes: Class 150, 300, 600 available

Connection Standards:

- Groove Standard: ANSI/AWWA C606 dimensions

- Groove Types: Single groove or double groove styles

- Gaskets: EPDM, NBR, Viton options

- Coupling Compatibility: Victaulic, Gruvlok, or other standards

- Ends: Grooved x Grooved standard

How to Select Grooved Resilient Seated OS&Y Gate Valve Model No. Z81X

Key Steps:

- Identify Service Conditions:Temperature,pressure,media,corrosion factors

- Specify Groove System:Must match existing piping or specify complete system

- Determine Material Requirements:Based on service conditions

- Select Pressure Class:150,300,or 600 psi rating

- Choose Supplier:Industrial valve specialist with grooved system expertise

Critical Specifications:

- Pressure-temperature rating

- Groove style and dimensions

- Material specifications for body and trim

- Packing material(standard or high-temp)

- Actuator mounting provisions if needed

Important Considerations:

- Confirm groove compatibility with existing couplings

- Consider future maintenance and removal requirements

- Specify special materials for corrosive service

- Verify pressure rating matches system design pressure

Pre-Shipment Inspection for Export Grooved Resilient Seated OS&Y Gate Valve Model No. Z81X and Key Considerations

Documentation Check:

- Material Test Reports (ASTM compliance)

- Pressure Test Certificates

- Groove Dimension Certification

- NDT reports if specified (RT, UT, MT)

- Heat treatment certificates if applicable

Physical Inspection:

OS&Y Mechanism Verification

Smooth rising stem through full travel

Proper yoke-stem alignment

Thread condition on exposed stem

Backseat function verification

Groove Precision Inspection

Exact groove width and depth measurements

Smooth groove surface finish

Proper outside diameter at grooves

No damage to groove edges or surfaces

Industrial Service Checks

Bolted bonnet integrity (if applicable)

Stud/nut quality and tightening

Gland packing adjustment capability

Pressure boundary verification

Pressure Testing

Shell test: 1.5 × rated pressure

Seat test: 1.1 × rated pressure (both directions)

High-pressure hold test if specified

Packing leakage test

Export Packaging:

- Groove protectors: Heavy-duty rigid sleeves mandatory

- Stem protection: Thread protectors on exposed rising stem

- Component separation: Yoke/handwheel protection if disassembled

- Moisture barrier: Complete weather protection for sea transport

- Heavy crating: Professional wooden crates for industrial valves

- Lifting points: Clearly marked for safe handling

Key Precautions:

- Groove protection: Absolute priority - damage renders valve unusable

- Stem alignment: Prevent bending during handling and shipping

- Industrial environments: Extra protection for harsh destination climates

- Documentation: Complete material and test certification package

- Heavy items: Professional rigging and secure transport

Final Shipping Documents:

- Commercial Invoice with detailed specifications

- Packing List with weights, dimensions, and component lists

- Bill of Lading

- Certificate of Origin

- Complete Technical Dossier (material certs, test reports, drawings)

- Groove Compatibility Specifications

- Installation, Operation & Maintenance Manual

Grooved Resilient Seated OS&Y Gate Valve Model No. Z81X Size Chart

| Dimensions | Pressure rating | Size(mm) | ||||||

| DN | inch | Psi | OD | L | H1 | H2 | H | Ф d |

| 50 | 2 | 362 | 60.3 | 178 | 358.5 | 420.5 | 403.5 | 203 |

| 65 | 2.5 | 362 | 73 | 190 | 359.5 | 429.5 | 411 | 203 |

| 76.1 | ||||||||

| 80 | 3 | 362 | 88.9 | 203 | 378 | 462 | 437.5 | 203 |

| 100 | 4 | 362 | 114.3 | 229

|

449.5 | 553 | 518.5 | 300 |

| 125 | 5 | 362 | 139.7 | 254 | 549.5 | 677 | 631 | 300 |

| 141.3 | ||||||||

| 150 | 6 | 362 | 165.1 | 267

|

591.5 | 747 | 686 | 300 |

| 168.3 | ||||||||

| 200 | 8 | 362 | 219.1 | 292 | 735.5 | 938 | 865 | 330 |

.png)

.png)