Flanged Swing Check Valve Model No. H44X-1.6

Flanged Swing Check Valve Definition and Components

A Flanged Swing Check Valve Model No. H44X-1.6 is an automatic, one-direction flow control valve designed for general industrial and commercial pipeline systems. The suffix "-1.6" specifically denotes its pressure rating of PN16 (16 bar, approximately 232 psi), making it suitable for medium-pressure applications. This model is part of the "H44X" series, where "H" indicates a check valve, "4" represents flanged ends, the second "4" signifies a swing disc design, and "X" denotes a resilient (rubber) seat for tight sealing.

Key Terminology:

- Flanged Ends:The valve has integral flanges for bolted connection to pipelines, ensuring robust and leak-proof installation.

- Swing Disc:The closure mechanism is a hinged disc that swings open with forward flow and closes automatically to prevent backflow.

- Resilient Seat:Features an elastomer sealing surface, providing bubble-tight closure and reducing water hammer effects compared to metal-to-metal seats.

- PN16 Rating:The valve is designed for a maximum working pressure of 16 bar at a specified temperature (usually 120°C for cast iron), following European (EN) and ISO pressure class standards.

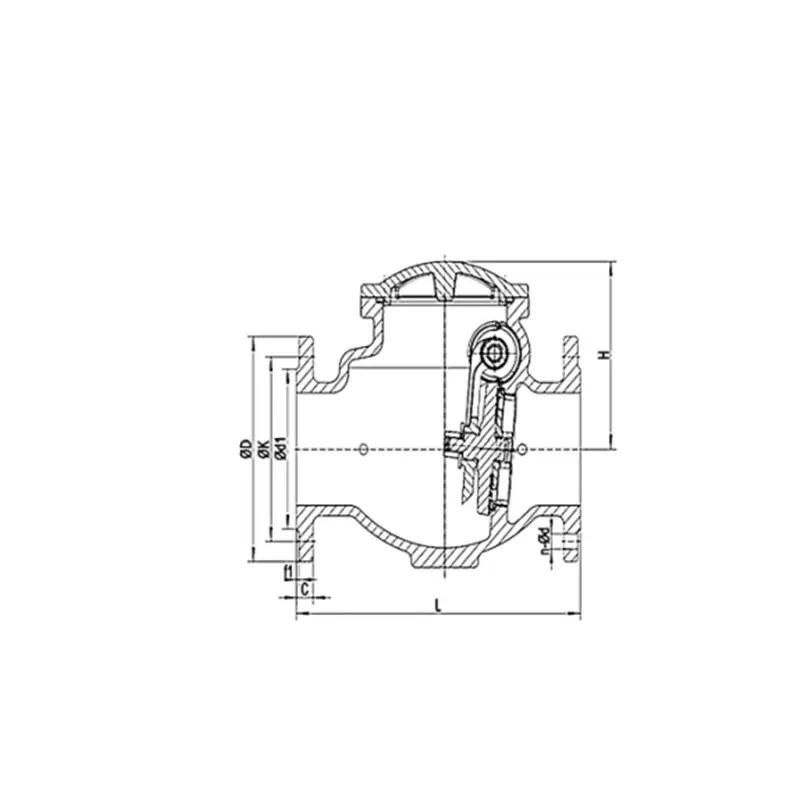

Fire Protection Check Valve Main Parts:

- Valve Body: The main pressure-containing component with integrally cast flanges.

- Cover/Bonnet: Provides access to internal parts and is bolted to the body.

- Disc: The swinging closure member that moves on a hinge.

- Hinge Pin/Arm Assembly: Allows the disc to pivot freely.

- Resilient Seat Ring: Made of elastomer (e.g., NBR, EPDM), mounted in the body to ensure tight sealing with the disc.

- Gasket: Seals the joint between the body and cover.

- Fasteners: Bolts, nuts, and washers for assembling the valve and connecting it to pipelines.

Role, Characteristics, and Application Scenarios of Flanged Swing Check Valve in Pipelines

Fire Check Valve Functions:

- Backflow Prevention:Automatically prevents reverse flow in pipelines, ensuring unidirectional flow.

- Equipment Protection:Safeguards pumps, compressors, and other equipment from damage caused by backflow.

- System Integrity:Maintains pressure and prevents contamination by isolating different sections of a system.

Operational Features:

- Automatic Operation:Functions based on flow dynamics—opens with forward flow and closes under backflow or gravity.

- Low Flow Resistance:The disc swings fully open, offering minimal obstruction to flow, which reduces pressure drop.

- Bubble-Tight Sealing:The resilient seat ensures near-zero leakage when closed.

- Horizontal Installation Required:Must be installed horizontally with the hinge pin axis horizontal to ensure proper disc swing and gravity-assisted closure. Vertical installation is not recommended unless specifically designed.

- Slam Potential:Like most swing check valves, it may experience disc slam under rapid flow reversal, leading to water hammer. For systems prone to this, a non-slam or spring-assisted check valve is preferred.

Primary Usage Scenarios:

This valve is commonly used in water supply, HVAC, industrial process lines, and irrigation systems where PN16 pressure rating is sufficient and backflow prevention is necessary.

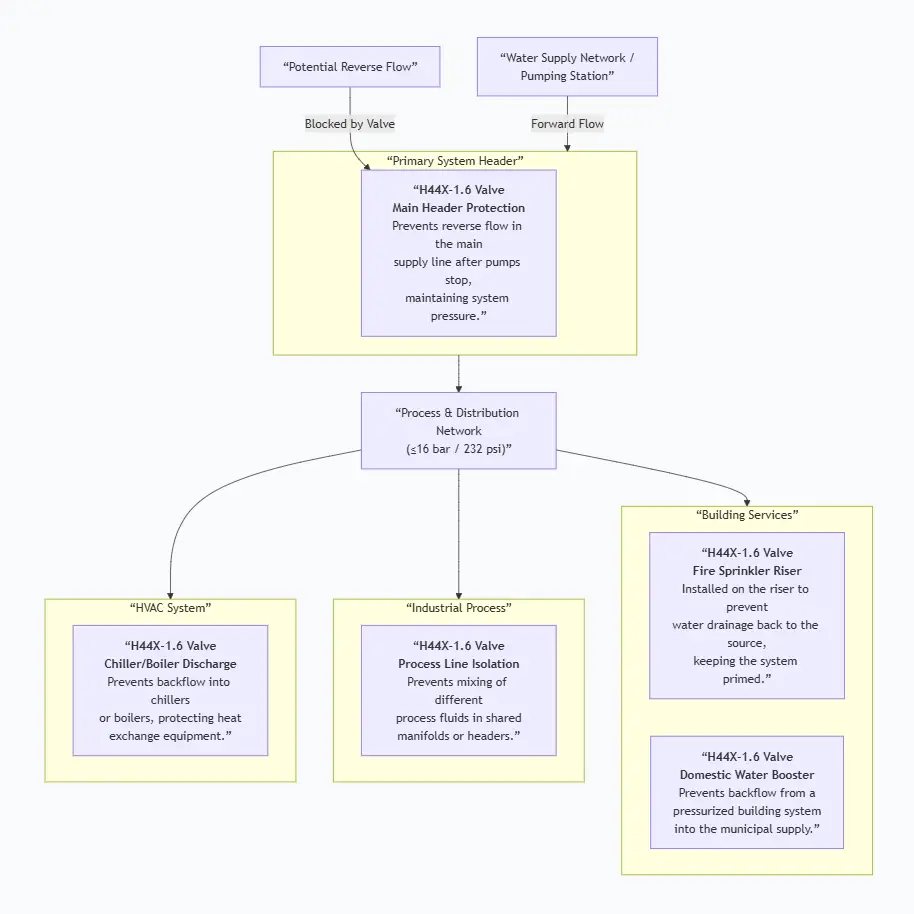

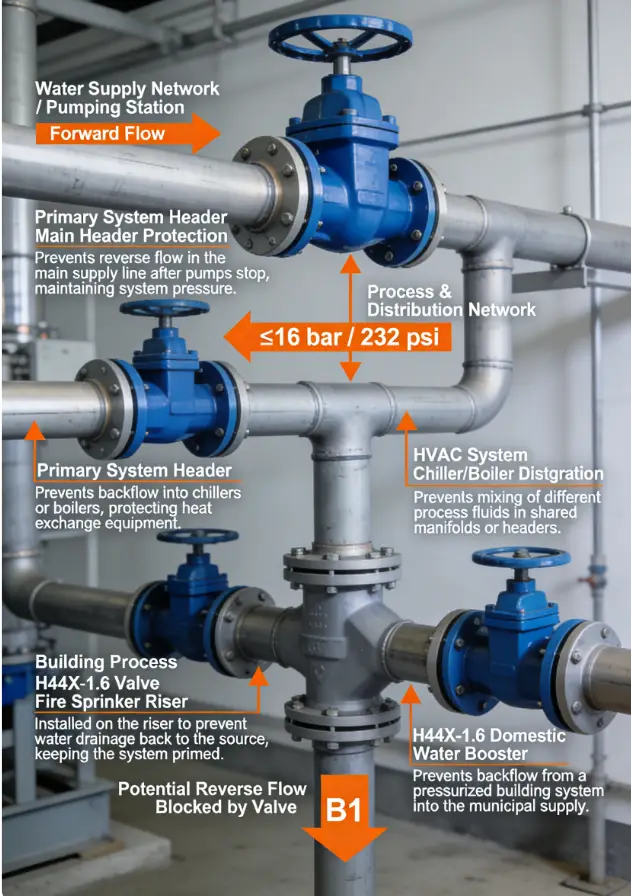

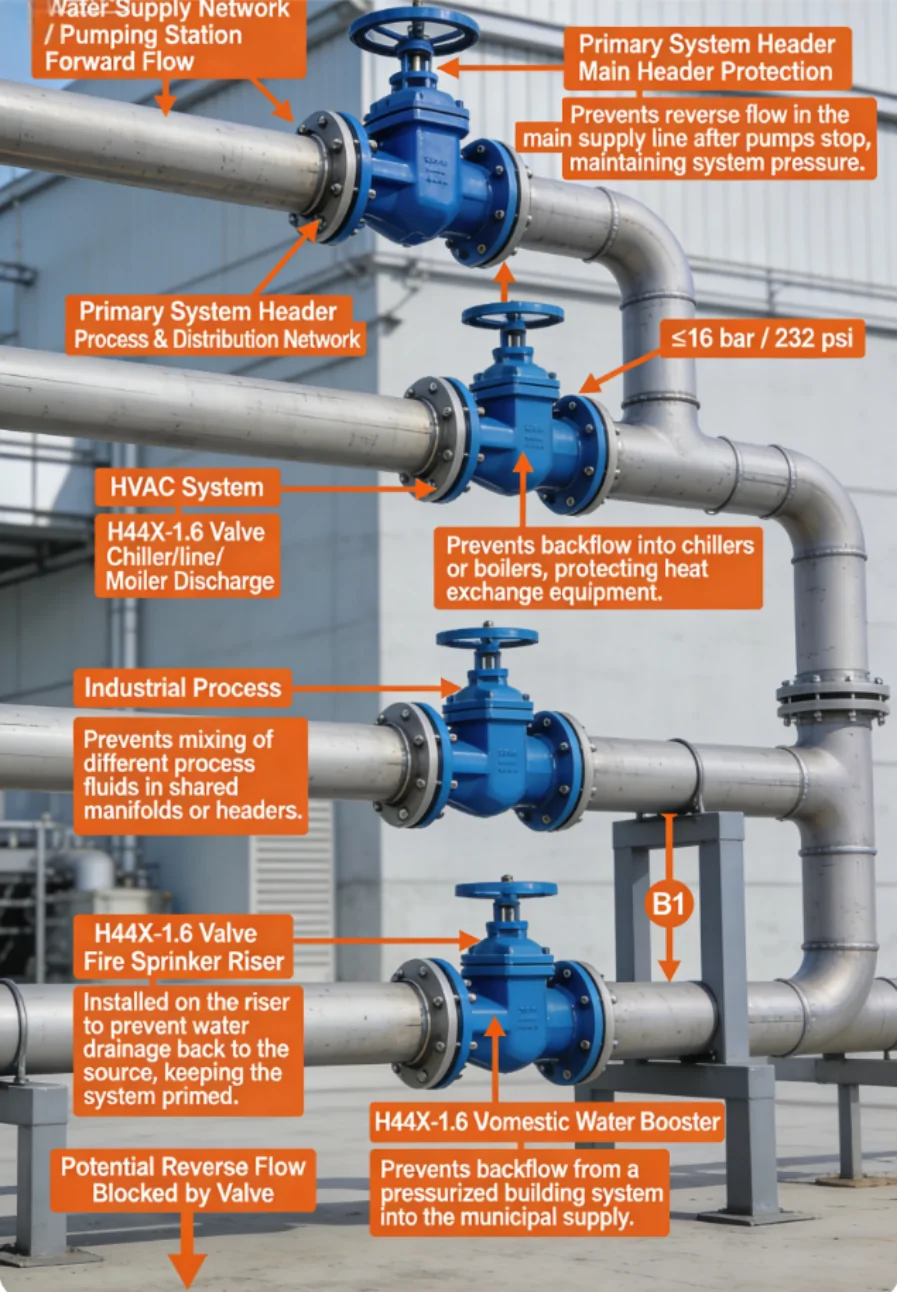

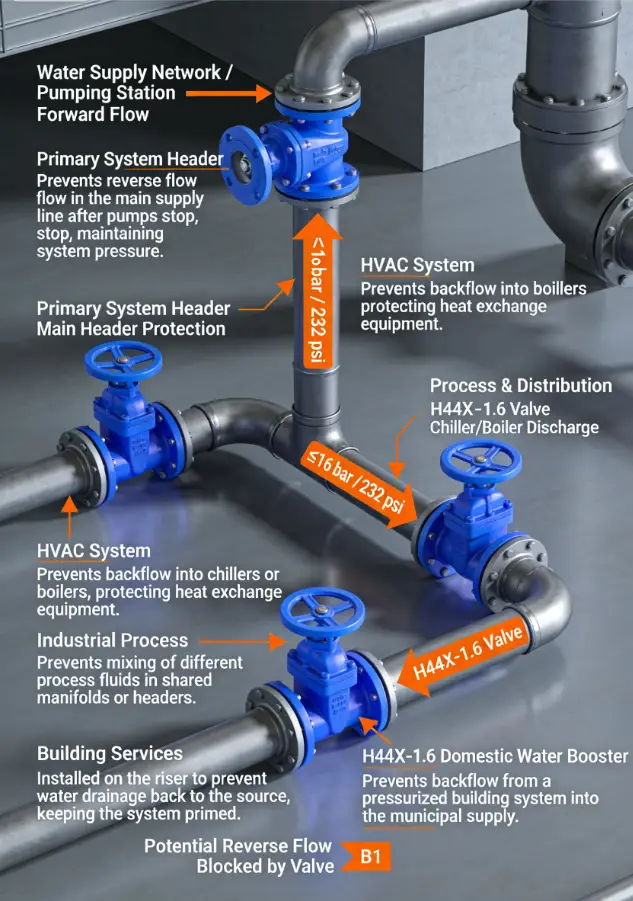

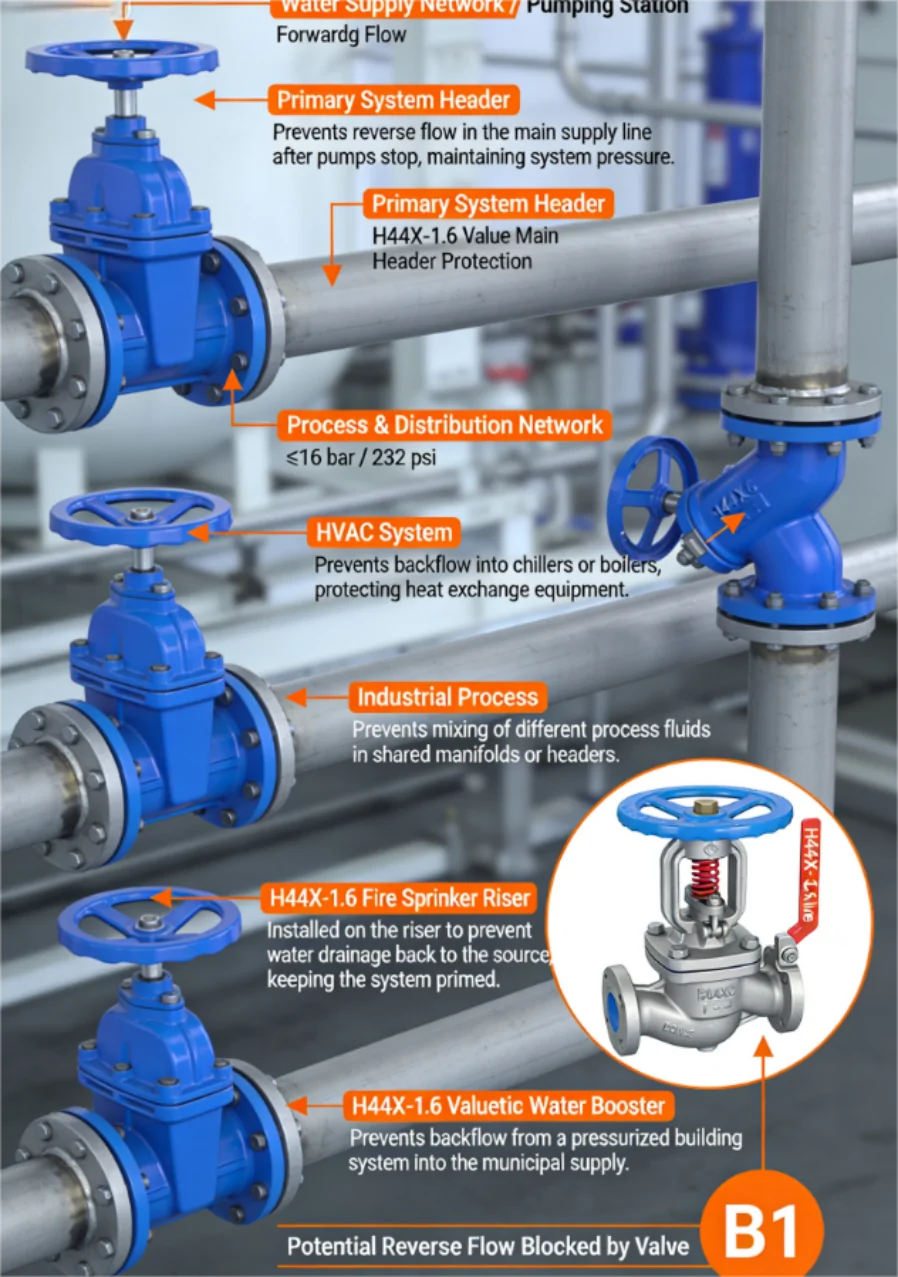

Scenario Diagram:

Flanged Swing Check Valve Standards: Materials, Design, and Connections

| Standard Type | Primary Standard(s) | Purpose & Key Specifications |

| Design & Dimensions | EN 12334 / ISO 17292 | European and International standards for check valves, covering design, dimensions, and testing. |

| Pressure-Temperature Rating | EN 1092-2 (PN rating) | Defines pressure-temperature ratings for flanged components, including PN16. |

| Flange Connection | EN 1092-2 (Type B - Flanges) | Specifies dimensions, sealing face types (e.g., Form B1 - raised face, Form D - tongue and groove), and drilling for PN-rated flanges. |

| Face-to-Face Length | EN 558-1 | Standardizes face-to-face dimensions for industrial valves. |

| Material Standards | EN 1561 (EN-GJL-250) / EN 1563 (EN-GJS-400-15) | For gray cast iron or ductile iron body/bonnet. |

| EN 10213-4 (GP240GH) for carbon steel castings. | ||

| EN 10269 (1.4408) for stainless steel trim. | ||

| Elastomers per EN 681-1 (e.g., EPDM, NBR). | ||

| Testing | EN 12266-1 | Specifies pressure test requirements and allowable leakage rates for valves. |

How to Select Flanged Swing Check Valve

Step 1: Define Technical Specifications

Ensure the valve meets the system requirements for PN16 pressure rating.

- Service Conditions:Specify fluid type, maximum temperature (e.g., 120°C for cast iron with EPDM seat), and design pressure (e.g., 16 bar).

- Size & Flange Details:Nominal Diameter (e.g., DN200) and Flange Standard (e.g., EN 1092-2 PN16, Form B1, Raised Face).

- Materials:Body material (e.g., Ductile Iron EN-GJS-400-15), seat material (e.g., EPDM per EN 681-1), disc and hinge pin material (e.g., Stainless Steel).

- Design Standard:Reference EN 12334 for design compliance.

- Special Requirements:If slam prevention is needed, consider a different model (e.g., spring-assisted check valve).

Step 2: Source and Evaluate Suppliers

- Source from manufacturers specializing in EN/ISO standard valves, particularly those with a CE marking if required for the European market.

- Request product data sheets, material certifications (e.g., 3.1 material certificates per EN 10204), and dimensional drawings.

- Verify that the valve is rated for PN16 and suitable for the intended service.

Step 3: Order Execution

- Confirm lead times and availability for required sizes and materials.

- Required documents: Commercial Invoice, Packing List, Certificate of Conformity (CoC), and Material Test Certificatesper EN 10204.

Pre-Shipment Inspection for Export Valves and Key Considerations

Fire Fighting Valve Inspection Checklist:

| Category | Check Point | Acceptance Criteria |

| Documentation | 1. Material Certificates | EN 10204 Type 3.1 certificates for pressure-retaining parts (body, cover). |

| 2. Test Certificate | Hydrostatic shell test and seat leakage test per EN 12266-1. | |

| 3. CE Marking Documentation | If applicable, ensure the valve has a CE mark and a Declaration of Conformity (DoC) for pressure equipment (PED). | |

| Physical/Functional | 4. Pressure Rating Marking | Verify the valve body is clearly marked with "PN16". |

| 5. Disc Movement & Hinge | Disc must swing freely without binding. Hinge pin must be secure with minimal play. | |

| 6. Seat Condition | Resilient seat must be intact, with no visible damage or deformation. | |

| 7. Flange Inspection | Check flange faces for scratches or damage. Verify flange dimensions (e.g., outer diameter, bolt circle) per EN 1092-2 for PN16. | |

| 8. Flow Direction Arrow | Must be clearly marked on the body. | |

| Packaging | 9. Disc Securement | The disc must be blocked or restrained in the closed position to prevent flailing during transit. |

| 10. Flange Protection | Use sturdy plastic or wooden protectors bolted to the flange faces. |

Key Precautions for Export:

- Immobilize the Disc:Secure the disc using a plastic clamp, wooden block, or strong nylon strap to prevent damage to the hinge pin and seat. This is critical for swing check valves.

- Protect Flange Surfaces:Use proper flange protectors that are bolted on, not just taped, to prevent damage to the sealing faces.

- Corrosion Prevention:Apply a suitable anti-corrosion coating or VCI (Vapor Corrosion Inhibitor) to all machined surfaces, especially the flange faces and bolt holes.

- Robust Crating:Due to the weight and shape, use strong wooden crates with internal bracing. Clearly mark the lifting points and "TOP" side on the crate.

- Documentation Pack:Include copies of the test certificates, material certificates, and installation manual in a waterproof bag inside the crate. Ensure the commercial documents state the correct pressure rating (PN16).

Flanged Swing Check Valve Size Chart

| Dimensions | Pressure rating | Size(mm) | ||||||||

| DN | inch | PN | D | K | d1 | C | f1 | n-d | H | L |

| 50 | 2 | 16 | 165 | 125 | 99 | 19 | 3 | 4-19 | 125 | 203 |

| 65 | 2.5 | 16 | 185 | 145 | 118 | 19 | 3 | 4-19 | 139 | 254 |

| 80 | 3 | 16 | 200 | 160 | 132 | 19 | 3 | 8-19 | 153 | 279 |

| 100 | 4 | 16 | 220 | 180 | 156 | 19 | 3 | 8-19 | 184 | 330 |

| 125 | 5 | 16 | 250 | 210 | 184 | 19 | 3 | 8-19 | 275 | 356 |

| 150 | 6 | 16 | 285 | 240 | 211 | 19 | 3 | 8-23 | 289 | 406 |

| 200 | 8 | 16 | 340 | 295 | 266 | 20 | 3 | 12-23 | 352 | 495 |

| 250 | 10 | 16 | 400 | 355 | 319 | 22 | 3 | 12-28 | 411 | 559 |

| 300 | 12 | 16 | 455 | 410 | 370 | 24.5 | 4 | 12-28 | 480 | 660 |

.png)

.png)