Air Releasing Valve BSPT Threaded Type

Air Releasing Valve BSPT Threaded Type Definition and Components

What is an Air Releasing Valve BSPT Threaded Type?

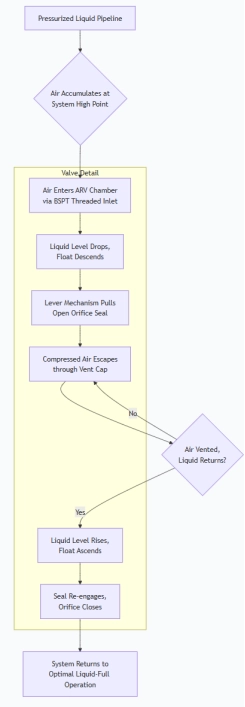

An Air Releasing Valve (ARV) with BSPT (British Standard Pipe Tapered) threads is an automatic valve designed to continuously vent small pockets of accumulated air from pressurized liquid pipeline systems. It features the globally common BSPT thread standard, making it particularly suitable for markets following British/European/Asian standards.

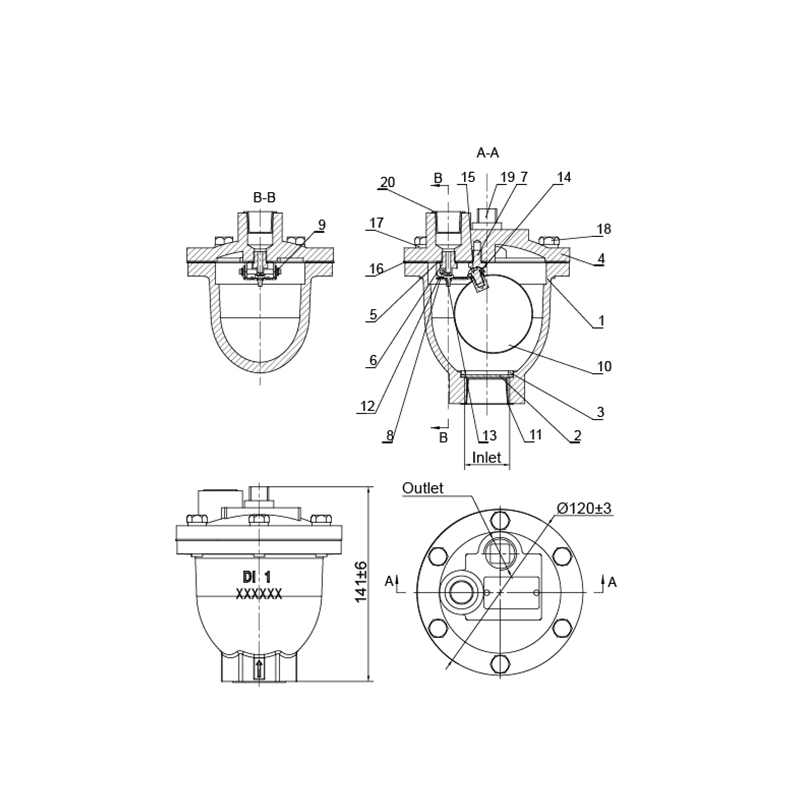

Main Components:

- Valve Body: The primary housing containing all internal mechanisms, manufactured with female BSPT threaded ports.

- Float Assembly: The sensing and actuating core.

- Float: A sealed hollow sphere or cylinder (stainless steel or engineered plastic) that moves vertically with the liquid level in the chamber.

- Lever Arm: Connects the float to the sealing mechanism.

- Lever & Pin Mechanism: Translates the vertical motion of the float into the opening/closing action of the seal.

- Orifice & Seal Assembly: A precision small-diameter orifice and its elastomeric or metal seal that controls air release.

- Protective Cap/Dome: A threaded cover with vent holes that protects internal components from debris while allowing vented air to escape.

- Seals & Gaskets: Ensure pressure integrity at all joints (typically EPDM, NBR, or FKM).

Role, Characteristics, and Application Scenarios of Air Releasing Valve BSPT Threaded Type in Pipelines

Primary Functions in Pipelines:

- Continuous Micro-Venting: Automatically expels small air pockets that accumulate at system high points during normal operation.

- Maintain Hydraulic Efficiency: Prevents flow restriction, pump cavitation, and energy loss caused by air accumulation.

- System Protection: Reduces corrosion (oxygen in air) and prevents water hammer caused by compressed air pockets.

- Pressure Maintenance: Helps maintain consistent system pressure by eliminating compressible air volumes.

Key Operational Features:

- Automatic Operation: Self-actuating based on liquid level - opens when air enters (float drops), closes when liquid returns (float rises).

- Small Capacity Design: Optimized for continuous release of small air volumes, not for rapid filling/draining.

- BSPT Connection: Features tapered threads per ISO 7-1 standard, ensuring pressure-tight sealing without sealants in some applications.

Typical Application Scenarios:

- Installed at local high points in closed-loop liquid systems.

- Hot Water Heating Systems & Chilled Water Circuits

- Potable Water Distribution Networks (common in UK, EU, Middle East, Asia)

- Industrial Process Lines (chemical, pharmaceutical, food processing)

- Solar Thermal Systems

- Compressed Air System Drainage (used as automatic drain valves)

Operational Scenario Diagram:

Air Releasing Valve BSPT Threaded Type Standards: Materials, Design, and Connections

Material Standards:

- Body/Bonnet: Brass (CW617N/ CZ121/ CuZn39Pb3) most common, Ductile Iron (EN-GJS-500-7/ EN 1563) for higher pressures, Stainless Steel (AISI 304/316, EN 1.4301/1.4401) for corrosive applications.

- Float: Stainless Steel AISI 304/316 or Polypropylene/PTFE for chemical compatibility.

- Seals: EPDM (water, steam), NBR (oils, fuels), Viton/FKM (high temp, chemicals), PTFE (aggressive chemicals).

- Spring: Stainless Steel AISI 302/316.

Design & Performance Standards:

- EN 1074-4: "Valves for water supply - Fitness for purpose requirements and appropriate verification tests - Air valves" (European standard).

- ISO 12149: "Automatic air vents for heating systems" (International standard).

- BS EN 12266-1: "Industrial valves - Testing of metallic valves."

- WRAS Approval: (Water Regulations Advisory Scheme) for UK potable water applications.

- ACS/CE Marking: Often required for European market.

Connection Standard:

- BSPT (British Standard Pipe Tapered): ISO 7-1 (formerly BS 21). Tapered thread form (1:16 taper) that creates a pressure-tight seal through thread engagement.

- Common Sizes: ½" BSPT (R½), ¾" BSPT (R¾), 1" BSPT (R1), 1¼" BSPT (R1¼).

- Important Note: BSPT is often confused with BSPP (parallel). BSPT valves require careful thread identification and typically use thread sealant (PTFE tape or compound) for leak-proof installation.

How to Select Air Releasing Valve BSPT Threaded Type

Purchasing Process:

①Specification Development:

◦ Fluid Type & Temperature: Water, oil, chemical, glycol mixtures? Operating temperature range?

◦ Pressure Rating: Maximum working pressure (e.g., PN16, PN25, Class 150).

◦ Connection Details: Exact BSPT size and gender (typically female).

◦ Material Specification: Brass for general use, stainless for corrosive/ marine environments.

◦ Seal Material Selection: Based on fluid compatibility and temperature.

◦ Certification Requirements: WRAS, ACS, CE, ISO 9001, customer-specific approvals.

②Supplier Identification:

◦ European Valve Specialists: (e.g., IMI Pneumatex, Caleffi, Spirax Sarco, Oventrop).

◦ International Manufacturers with BSPT Lines: (e.g., Armstrong, Watts, BERMAD).

◦ Asian Manufacturers: Many Chinese/Taiwanese suppliers produce BSPT valves for export markets.

③ Quotation & Evaluation:

◦ Request detailed datasheets with pressure/temperature curves.

◦ Verify material certifications (3.1B Material Certificates per EN 10204).

◦ Request samples for testing, especially for large-volume orders.

◦ Clarify: MOQ, lead time, packaging, Incoterms (FOB, CIF, DAP).

Pre-Shipment Inspection for Export Air Releasing Valve BSPT Threaded Type and Key Considerations

Comprehensive Inspection Checklist:

| Inspection Area | Check Points | Acceptance Criteria |

| Visual & Dimensional | Body casting quality | No cracks, porosity, or defects |

| Thread inspection (BSPT) | Clean, undamaged threads; verify with gauge | |

| Float mechanism freedom | Smooth vertical movement without sticking | |

| Markings completeness | Size, pressure rating, material, flow direction, brand | |

| Material Verification | Body material | Confirm via MTR against purchase order |

| Seal material | Documentation confirming elastomer type | |

| Float material | Stainless steel or certified polymer | |

| Functional Testing | Seat Leak Test | Immerse in water, apply air pressure (1.1x rated), no bubbles |

| Float Response Test | Manual operation - air passage when float down, sealed when up | |

| Pressure Hold Test | Hold rated pressure for 5 minutes, no visible leakage | |

| Documentation Review | Certificates of Conformity | Complies with PO requirements |

| Material Test Reports | EN 10204 3.1B for metallic parts | |

| Test Certificates | Factory test records available | |

| Packing List Accuracy | Correct quantities, models, parts | |

| Packaging Assessment | Individual protection | Anti-corrosion wrap, desiccant in bag |

| Thread protection | Plastic caps on all threaded ports | |

| Carton strength | Suitable for export transit, "Fragile" markings | |

| Shipping marks | Clear, permanent, correct destination info |

Air Releasing Valve BSPT Threaded Type Material List

| S/N | Description of Parts | Materials |

| 1 | Valve Body | Ductile Iron |

| 2 | Filter Screen | SS316 |

| 3 | Gasket Ring | Carbon Steel |

| 4 | Bonnet | Ductile Iron |

| 5 | Yoke | SS316 |

| 6 | Valve Seat | SS316 |

| 7 | Bolt | SS316 |

| 8 | Valve Shaft | SS316 |

| 9 | E Type Retainer Ring | SS304 |

| 10 | Ball | SS316 |

| 11 | Large Protective Cover | Plastic |

| 12 | Lever | SS316 |

| 13 | Poppet | EPDM |

| 14 | Spring Washer | SS316 |

| 15 | Hex Socket Head Bolt | SS304 |

| 16 | Asbestos-free Gasket | CN-705 |

| 17 | Spring Washer | Carbon Steel |

| 18 | Bolt | Carbon Steel |

| 19 | Plug | Ductile Iron |

| 20 | Small Protective Cover | Plastic |

.png)

.png)