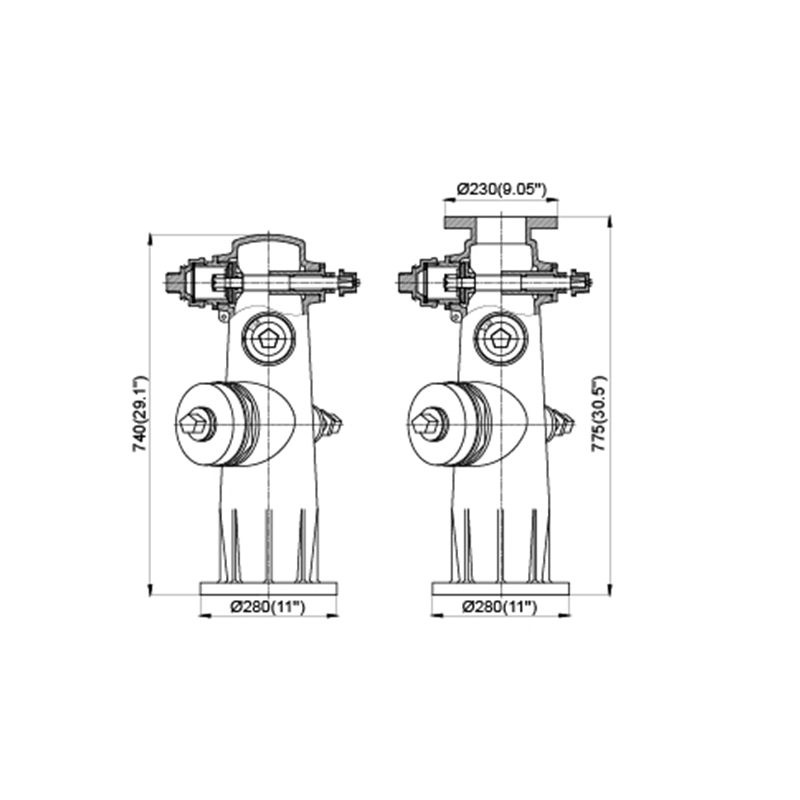

Wet Hydrant Model No. MH-1511 1511A 1512 1512A

Wet Hydrant Definition and Components

What is a Wet Barrel Fire Hydrant?

The MH-1511 Series Wet Barrel Hydrant is a pressurized, above-ground fire protection water supply point designed for non-freezing climates. Unlike dry barrel hydrants, the entire hydrant body, including the main valve and operating mechanism, remains constantly filled with pressurized water from the municipal supply main.

Model Number Breakdown:

| Model | Configuration | Typical Specifications |

| MH-1511 | Standard 2-hose outlet | 4.5" pumper + 2 x 2.5" hose |

| MH-1511A | 1511 with AWWA threads | NST threads for North America |

| MH-1512 | 3-hose outlet | 4.5" pumper + 3 x 2.5" hose |

| MH-1512A | 1512 with alternative threads | BSP threads for international |

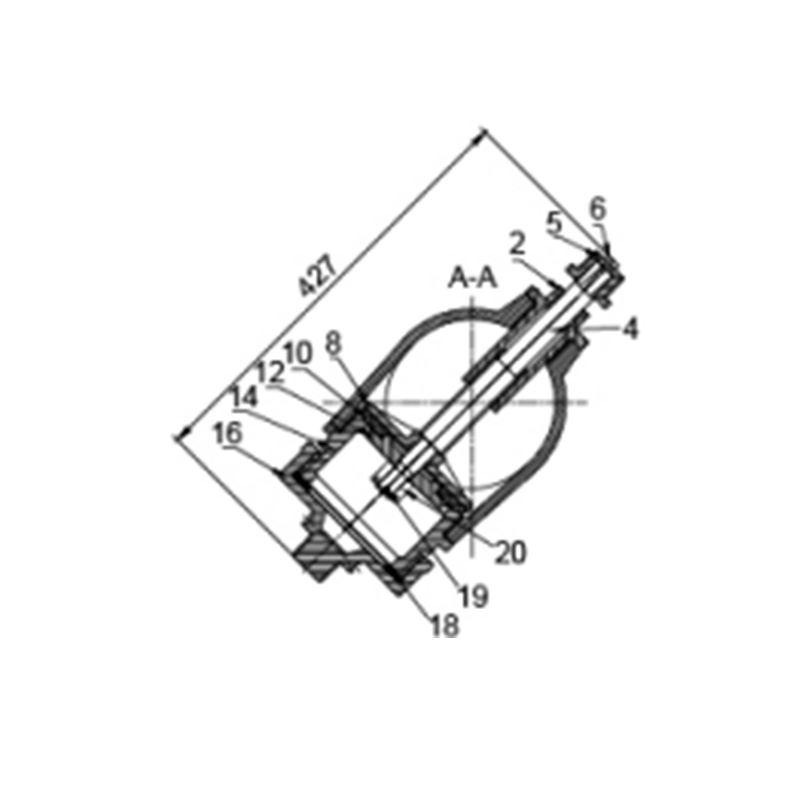

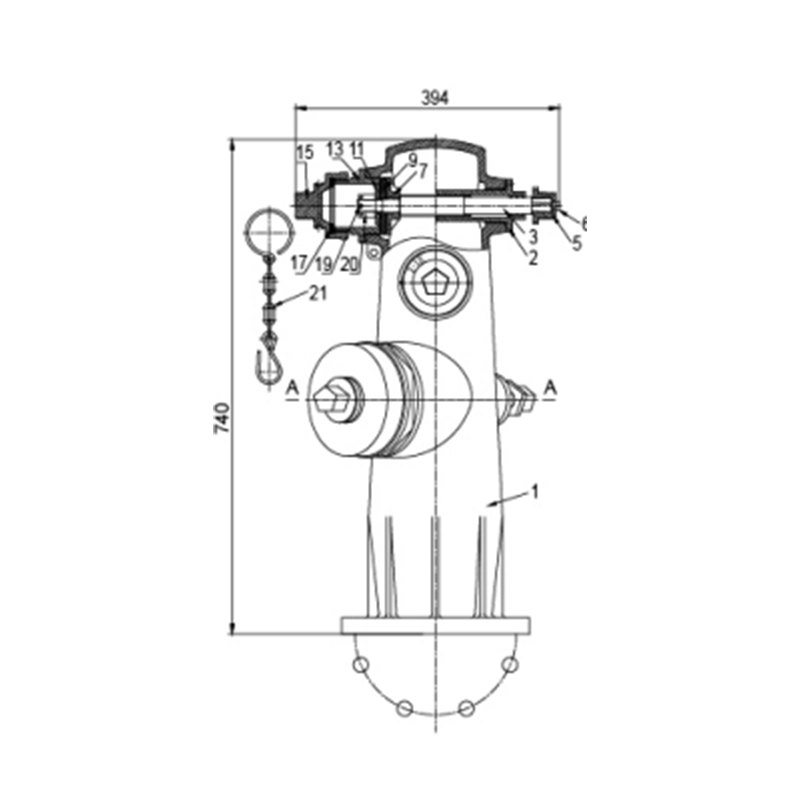

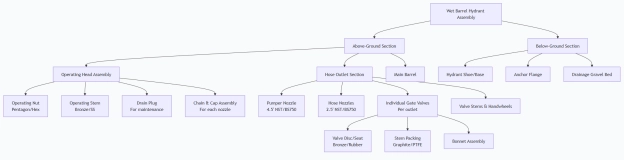

Main Components & Assembly:

Key Component Details:

- Hydrant Body/Barrel: ASTM A536 Ductile Iron, constantly pressurized

- Individual Outlet Valves: Independent gate valves for each outlet

- Operating Mechanism: Direct-acting stem to valve (no drain mechanism)

- Nozzle Caps: Threaded caps with chains, O-ring sealed

- Breakaway Sections: Frangible bolts or couplings for vehicle impact protection

Role, Characteristics, and Application Scenarios of Wet Hydrant in Pipelines

Wet Hydrant Primary Functions:

- Immediate Water Access: Provides instant pressurized water without draining/preparation

- Multiple Outlet Operation: Allows simultaneous connections from different outlets

- Municipal Interface: Connects fire apparatus directly to water supply grid

- Pressure Regulation: Some models include pressure - reducing features

Operational Features:

| Feature | Wet Barrel Advantage | Consideration |

| Readiness | Instant operation | Requires frost-free environment |

| Maintenance | Easier access to parts | More exposed to corrosion |

| Flow Capacity | Typically higher | Depends on main pressure |

| Reliability | Fewer moving parts below ground | Valve maintenance above ground |

| Installation | Simpler, shallower burial | Requires precise alignment |

Operation Sequence Diagram:

Wet Hydrant Standards: Materials, Design, and Connections

Material Standards Matrix:

| Component | Standard Material | Specification | Alternative |

| Hydrant Body | Ductile Iron | ASTM A536 Grade 65-45-12 | Cast Iron ASTM A126 |

| Valve Trim | Bronze | ASTM B584 C83600/84400 | Stainless Steel AISI 316 |

| Operating Nut | Ductile Iron/Bronze | AWWA C502 | Coated Steel |

| Stems | Bronze/Stainless | ASTM B584/A276 | |

| Seats | Bronze + Rubber | EPDM/NBR seats | |

| Gaskets | EPDM/Nitrile | Temperature rated | Viton for chemical |

| Caps/Chains | Ductile Iron + Galv | ASTM A153 coating |

Design & Performance Standards:

Fire Hydrant Primary Standards:

- AWWA C502: Standard for Dry - Barrel Fire Hydrants

- NFPA 291: Recommended Practice for Fire Flow Testing

- UL/FM Approval: For insurance requirements

- ISO 9001: Quality management system

Regional Additions:

- BS 750: UK specification for fire hydrants

- AS 2419: Australian fire hydrant systems

- DIN 3221: German hydrant specifications

Connection Standards:

| Connection Type | Standard | Thread Type | Region |

| Pumper Outlet | AWWA C502 | 4.5" NST (National Standard) | North America |

| Hose Outlets | AWWA C502 | 2.5" NST | North America |

| Alternative | BS 750 | 2.5"/3"/4" BSP | International |

| Inlet Connection | AWWA C153 | 6" MJ (Mechanical Joint) | Standard |

| Flange Option | ANSI B16.1 | Class 125/250 | Custom |

Performance Specifications:

| Parameter | MH-1511 | MH-1512 | Test Standard |

| Working Pressure | 150 psi (10.3 bar) | 150 psi (10.3 bar) | AWWA C502 |

| Test Pressure | 300 psi (20.7 bar) | 300 psi (20.7 bar) | Hydrostatic |

| Flow Rate @ 20 psi | 1000 GPM | 1200 GPM | NFPA 291 |

| Main Valve Size | 5.25" | 5.25" | - |

| Inlet Size | 6" | 6" | - |

| Outlets | 2 hose + 1 pumper | 3 hose + 1 pumper | - |

How to Select Wet Hydrant?

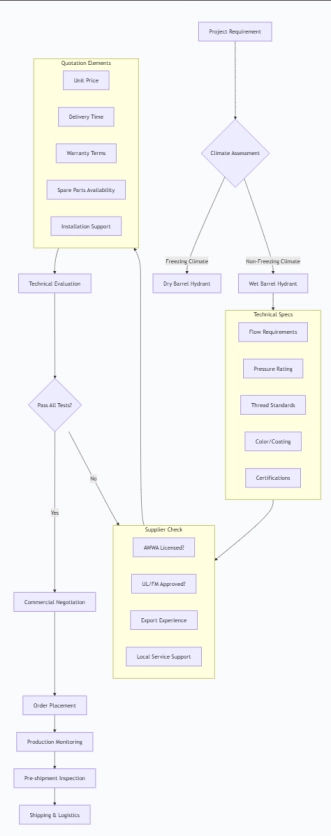

Procurement Flowchart:

Key Purchase Considerations:

Technical Requirements Checklist:

- Climate suitability confirmed (non - freezing)

- Flow rate requirements documented

- Thread standards match local fire department equipment

- Color coding per local regulations (red, yellow, etc.)

- Installation accessories included (wrenches, gaskets)

- Impact protection requirements defined

- Marking/labeling in local language

- Supplier Qualification Criteria:

- Manufacturing Capability:

- Annual production capacity > 5,000 units

- In - house foundry and machining

- ISO 9001 certified for 3+ years

- Certification Portfolio:

- AWWA C502 compliance

- UL/FM listings

- CE marking for European markets

- Local country approvals (e.g., SIRIM for Malaysia)

- Commercial Terms:

- Payment: 30% advance, 70% against shipping docs

- Warranty: Minimum 5 years

- Lead time: 60 - 90 days for production

- MOQ: Typically 10 - 50 units

Pre-Shipment Inspection for Export Wet Hydrant and Key Considerations

Inspection Stages & Criteria:

Detailed Inspection Checklist:

| Test Category | Test Method | Acceptance Criteria | Tools Required |

| Visual | Surface examination | No cracks, porosity, casting defects | Magnifying glass |

| Dimensional | Thread verification | NST/BSP threads to gauge | Thread gauges set |

| Material | PMI verification | Matches ASTM/AWWA specs | XRF analyzer |

| Pressure | Hydrostatic test | 2x working pressure, 2 min, no leaks | Pressure pump, gauge |

| Functional | Valve operation | Smooth 360° rotation, full open/close | Torque wrench |

| Flow | Flow rate test | ≥ Rated GPM at 20 psi residual | Flow meter, pitot gauge |

| Coating | Thickness measurement | 250-300 microns minimum | Coating thickness gauge |

| Markings | Permanent ID check | Model, pressure, date, manufacturer | - |

Specific Test Procedures:

Hydrostatic Pressure Test:

Valve Operation Test:

- Torque measurement: ≤ 50 ft - lbs for full operation

- Cycles: Open/close 10 times minimum

- Smoothness: No binding or excessive play

Flow Performance Test:

- Connect to calibrated flow test rig

- Measure at 20, 40, 60 psi residual pressure

- Verify against manufacturer's flow curve

- Minimum acceptable: 1000 GPM @ 20 psi for MH - 1511

- Critical Export Precautions:

Climate Protection:

- Internal drying after hydro testing (compressed air blow - through)

- Desiccant calculation: 10g per cubic foot of air space

- VCI paper with 12 - month protection guarantee

Physical Protection:

- Frangible bolt torque verification (shear at specified torque)

- Nozzle protection caps with security chains

- Impact - absorbing foam at stress points

Regulatory Compliance:

- Country - specific certifications included in shipment

- RoHS compliance declaration for coatings

- REACH compliance for European destinations

Logistics Planning:

- FOB/CIF terms clearly defined

- Container loading plan (max 20 units per 40' container)

- Port handling instructions included

- Notify Party clearly identified

- Post - Shipment Support Protocol:

Fire Valves Delivery Verification:

- GPS tracking provided

- Photo evidence of delivery condition

- Signed delivery receipt requirement

- Installation Support:

- Video tutorials accessible via QR code

- Technical hotline in local business hours

- Spare parts availability guarantee

- Warranty Activation:

- Online registration within 30 days

- 5 - year warranty from installation date

- Extended warranty options available

Wet Hydrant Material List

.png)

.png)