Water Flow Switch

Water Flow Switch Technical Information

l.Overview

The vane type water flow switch use in wet pipe systems only

Water flow in the pipe deflects a vane, which produces a switched

output usually after a specified delay

ll.Main Components

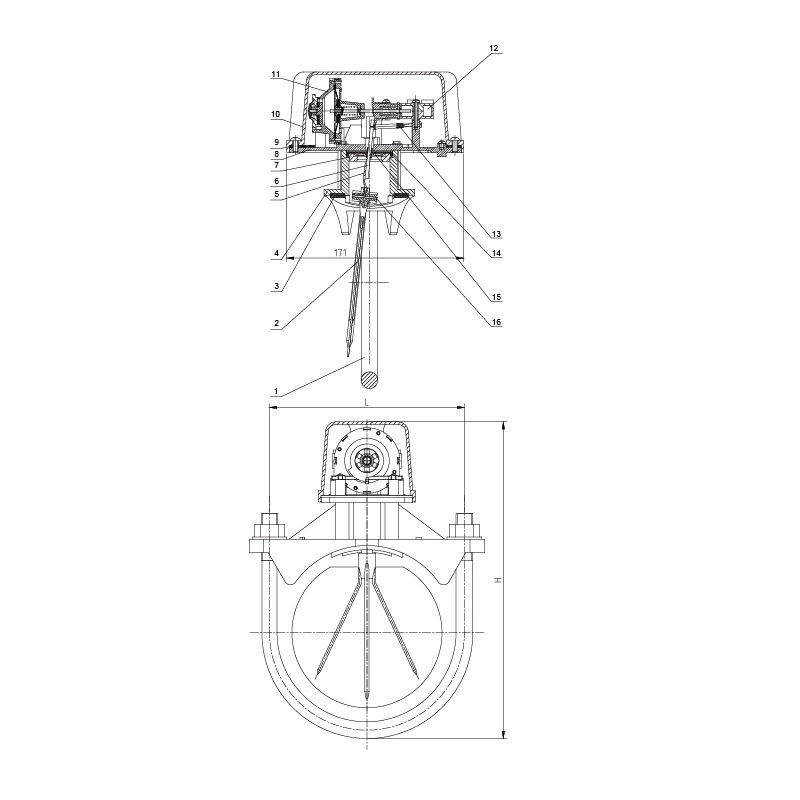

ZSJZ series water flow indicator is mainly composed of the saddle

blade rack,bottom plate, outer cover, Air delay device micro-switch,

junction box.etc.

- The main outline drawing is shown in Figure 1 Qutline Drawing

- Main dimensions of water flow indicator are shown in Table 1

- Materials of the main components are shown in Table 2

Water Flow Switch Definition and Components

Water Flow Switch is an electro-mechanical device that detects water flow in pipelines and activates an electrical switch when flow reaches a pre-set minimum rate. It provides early warning of water movement in fire protection and process systems.

Fire Sprinkler Valve Tamper Switch Main Components:

- Housing/ Body - Watertight enclosure containing all components

- Paddle or Vane - Flow-sensing element that deflects with water movement

- Switch Mechanism - SPDT (Single Pole Double Throw) or DPDT electrical switch

- Retard Mechanism - Prevents false activation from water hammer or surges

- Adjustment Mechanism - Sets the trip point for flow rate

- Electrical Conduit Connection - For wiring to alarm/control panels

- Test Mechanism - Manual test lever or magnet for testing

- Seals & Gaskets - Ensure watertight integrity

Role, Characteristics, and Application Scenarios of Water Flow Switch in Pipelines

Fire Valve Primary Functions:

- Flow Detection: Senses water movement in pipelines

- Alarm Activation: Triggers electrical signals when flow occurs

- System Monitoring: Provides supervision of water-based systems

- Pump Control: Can activate/deactivate pumps based on flow

Operational Features:

- Adjustable Sensitivity: Field-adjustable trip points

- Retard Feature: Time delay prevents false alarms

- Visual Indicator: Often includes status LED or flag

- Manual Test: Field-testable without water flow

- Fail-Safe Design: Typically fails to alarm position

Application Scenarios:

- Fire Sprinkler Systems: Detects sprinkler activation

- Fire Pumps: Monitors pump operation

- Industrial Processes: Flow monitoring in cooling/heating systems

- Water Treatment: Filter backwash cycle detection

- Building Management: HVAC system flow monitoring

Water Flow Switch Standards: Materials, Design, and Connections

Material Standards:

- Body/Housing: Brass (ASTM B584), Bronze, Cast Iron, or Stainless Steel

- Paddle/Vane: Stainless Steel 304/316 or engineered plastics

- Electrical Components: UL-listed, CSA-approved

- Seals: EPDM, Viton, or Buna-N based on temperature

- Fasteners: Stainless steel A2/A4 grade

Design Standards:

- UL 508: Standard for Flow Switches

- FM 1320: Approval Standard for Waterflow Alarm Devices

- NFPA 72: National Fire Alarm and Signaling Code

- EN 54-18: Fire detection and fire alarm systems - Input/output devices

- ISO 7241-2: Hydraulic fluid power - Pressure switches

Connection Standards:

- Pipe Connections: NPT threads (½", ¾", 1", 1½", 2")

- Flange Options: ANSI 125/150, DIN, JIS standards

- Electrical: ½" NPT conduit connection

- Wiring: Typically #14 AWG, SPDT or DPDT contacts

- Voltage: 24VAC/DC, 120VAC, 240VAC available

How to Select Water Flow Switch?

Purchasing Steps:

Technical Specification:

- Pipe size and connection type

- Required flow rate trip point

- Operating pressure range

- Fluid temperature range

- Electrical requirements (voltage, contact arrangement)

- Required certifications (UL, FM, VdS, LPCB)

Supplier Evaluation:

- UL/FM listing for fire protection applications

- Industry reputation and experience

- Technical support availability

- Delivery lead times

- Warranty terms

Documentation Requirements:

- UL/FM listing certificates

- Factory test reports

- Installation and maintenance manuals

- Dimensional drawings

- Material certifications

Commercial Considerations:

- Lead Time: 2-8 weeks

- Payment Terms: Net 30 typical

- Warranty: 1-3 years

- Shipping: Small parcel or palletized

- MOQ: Usually 1 unit

Pre-Shipment Inspection for Export Water Flow Switch and Key Considerations

Inspection Checklist:

| Area | Procedure | Acceptance Criteria |

| Visual | External inspection | No damage, proper markings |

| Mechanical | Paddle movement test | Smooth operation, proper range |

| Electrical | Continuity test | Switch operates correctly |

| Pressure | Hydrostatic test | No leaks at rated pressure |

| Adjustment | Trip point adjustment | Smooth, calibrated operation |

| Seals | Gasket inspection | Proper installation, no damage |

| Packaging | Export readiness | Adequate protection |

Export Precautions:

- Internal Drying: Complete drying after any testing

- Corrosion Protection: VCI paper for metal components

- Electrical Protection: Moisture barrier bags for electrical parts

- Thread Protection: Plastic caps on all pipe connections

- Documentation: Include multilingual installation guide

Real-World Hospital Application:

In this ICU scenario, the water flow switch provides critical early fire detection through multiple integrated systems:

- Immediate Alarm Activation: Within 30 seconds of sprinkler operation

- Specific Location Identification: Precisely identifies the affected zone (ICU West Wing)

- Integrated Emergency Response: Triggers building-wide safety systems

- Reliable Operation: Mechanical design ensures functionality even during power outages

The adjustable retard timer (5-90 seconds) prevents false alarms from water hammer while ensuring genuine fire events are quickly detected. The manual test magnet allows regular testing without water flow, essential in hospital environments where water discharge must be minimized.

Key Hospital-Specific Features:

- Materials: Corrosion-resistant for frequent cleaning

- Reliability: High reliability to prevent unnecessary patient evacuation

- Integration: Seamless connection to nurse call and security systems

- Maintenance: Easy testing procedures for busy hospital staff

- Documentation: Comprehensive records for regulatory compliance

This installation demonstrates best practices in healthcare fire protection, where early, reliable detection is critical for patient safety and regulatory compliance. The flow switch serves as the primary detection method for sprinkler activation, providing the fastest possible warning while minimizing false alarms that could disrupt critical patient care activities.

Water Flow Switch Dimensions

.png)

.png)