Angle Hose Valve F&M

Angle Hose Valve F&M Definition and Components

An Angle Hose Valve (F & M) is a specialized quarter-turn ball valve designed for fire protection standpipe and hose systems. The "Angle" refers to its 90-degree body configuration, where the outlet is perpendicular to the inlet. "F & M" denotes the thread types: "F" for Female (internal) pipe thread at the inlet, and "M" for Male (external) hose thread at the outlet. It serves as a controlled connection point for a fire hose.

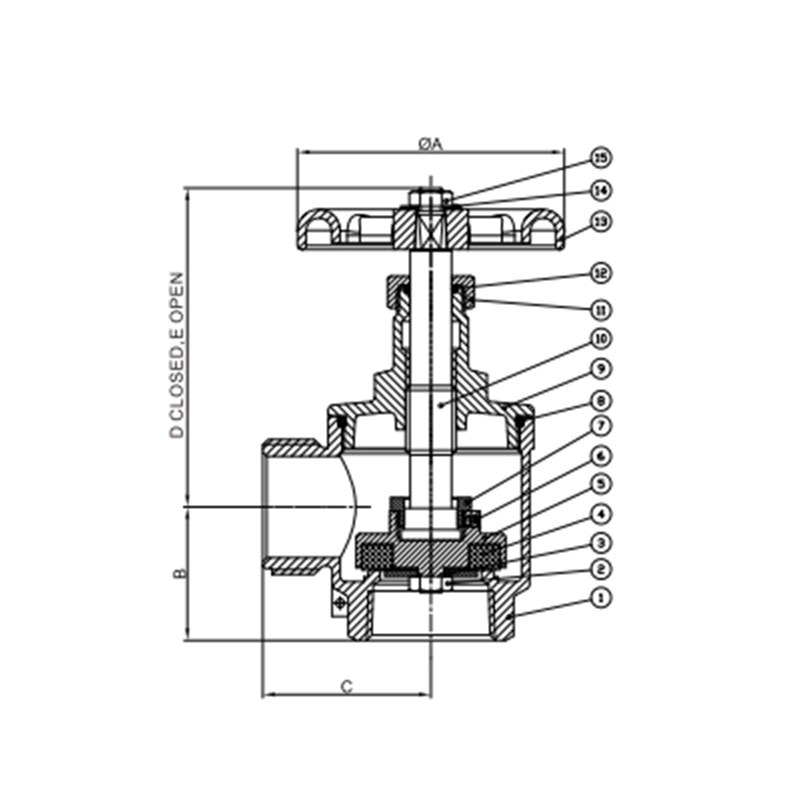

Main Parts:

- Angled Body: Ductile iron or bronze casting forming a 90-degree flow path.

- Ball & Stem Assembly: Chrome-plated brass or stainless steel ball with a through-hole, connected to the operating stem.

- Quick-Open/Close Handle: Lever for quarter-turn operation, often with a padlock provision.

- Inlet Connection (F): Female pipe thread (e.g., NPT) to connect to the standpipe.

- Outlet Connection (M): Male fire hose thread (e.g., NST) to connect the fire hose.

- Seats & Seals: Resilient EPDM or PTFE seals for tight shut-off.

Role, Characteristics, and Application Scenarios of Angle Hose Valve F&M in Pipelines

Fire Valves Functions in Pipelines:

- Hose Connection Point: Provides a dedicated, valved outlet for a fire hose on a standpipe system.

- Flow Control: Allows firefighters to quickly start, stop, and regulate water flow to the attached hose.

- System Isolation: Isolates the hose line from the standpipe main for maintenance.

- Freeze Protection: The automatic drain empties the valve body when closed to prevent water accumulation and freezing.

Operational Features:

- Quarter-Turn Operation: Lever allows for fast, full-open or full-close action.

- Hose Thread Outlet: Standardized male fire department thread (e.g., 1.5" NST).

- Automatic Drain: A small hole or channel that drains water from the valve body cavity upon closure.

- Pressure Rating: Typically 175 psi or higher for fire service.

Common Scenarios:

- Building Standpipes: Installed on each floor's hose cabinet or hose rack.

- Industrial Fire Lines: On wet or dry standpipe systems in warehouses and factories.

- Fire Department Connection (FDC): As the valve on the siamese connection's outlet.

- Scenario Diagram: Typical Installation on a Standpipe

Angle Hose Valve F&M Standards: Materials, Design, and Connections

Material Standards:

- Body: ASTM A536 (Ductile Iron) or ASTM B62 (Bronze). Exterior epoxy coated.

- Internals (Ball, Stem): ASTM A276 Type 316 Stainless Steel or chrome-plated brass.

- Seats/Seals: EPDM (standard) or Viton for chemical resistance.

Design & Performance Standards:

- UL 668 / FM 1311: Standard for Fire Department Hose Valves. Governs design, performance, endurance, and fire resistance.

- NFPA 14: Standard for the Installation of Standpipe and Hose Systems. Dictates installation requirements.

- Hydrostatic Test Pressure: Typically 2x or 3x the working pressure.

Connection Standards:

- Inlet (Female - F): NPT (National Pipe Tapered) thread per ANSI/ASME B1.20.1. Common sizes: 1.5", 2.0", 2.5".

- Outlet (Male - M): NST (National Standard Thread) or NH (National Hose) fire hose thread per NFPA 1963. Common sizes: 1.5" or 2.5".

How to Select Such Valves?

Follow this purchasing guide:

Define Specifications:

- Size & Threads: Inlet pipe size (e.g., 2" NPT Female) and outlet hose size/thread (e.g., 1.5" NST Male).

- Pressure Rating: Match standpipe system design pressure (e.g., 175 PSI WP).

- Material: Specify Ductile Iron body with epoxy coat and stainless trim.

Verify Mandatory Certifications:

- The valve MUST be UL Listed (UL 668) or FM Approved (FM 1311). Request the listing card.

- Confirm compliance with local fire codes (e.g., NFPA 14, IBC).

Brass Valves Supplier Selection:

- Source from reputable fire protection or industrial valve suppliers.

- Compare pricing from different brands (e.g., Potter, Akron, Naffco, local manufacturers).

- Request a sample or CAD drawing for approval on critical projects.

Pre-Shipment Inspection for Export Angle Hose Valve F&M and Key Considerations

Inspection Procedure:

Visual & Dimensional Check:

- No cracks, porosity, or defects in casting. Coating is even and intact.

- Handle operates smoothly (90-degree stop). No excessive play.

- Verify thread types and sizes with ring/plug gauges. Ensure threads are clean and undamaged.

- Check for permanent marking: Brand, Model, Size, Pressure Rating, UL/FM mark.

Functional & Pressure Test:

- Shell & Seat Test: Confirm factory hydrostatic pressure test certificate is provided (e.g., tested at 500 PSI for a 175 PSI valve).

- Drain Function: With valve closed, verify the automatic drain port is open and unobstructed.

- Operation: Cycle the valve open/close several times. Action must be smooth.

Packaging & Documentation:

- Thread Protection: Both inlet and outlet threads must have heavy-duty plastic caps securely threaded on.

- Internal Protection: Valve interior should be clean, dry, and free of oil/grease.

- Packaging: Individual carton with foam or cardboard inserts to prevent movement.

- Documents: Packing list, test certificate, and UL/FM listing documents must be included in the shipment.

.png)

.png)