ANGLE HOSE VALVE F&F

ANGLE HOSE VALVE F&F Definition and Components

An ANGLE HOSE VALVE F&F is a quarter-turn ball valve designed specifically for fire protection standpipe and hose systems. The "ANGLE" indicates its 90-degree body configuration. "F&F" denotes Female connections on both the inlet and outlet ports. It serves as a controlled connection point between the standpipe piping and a fire hose.

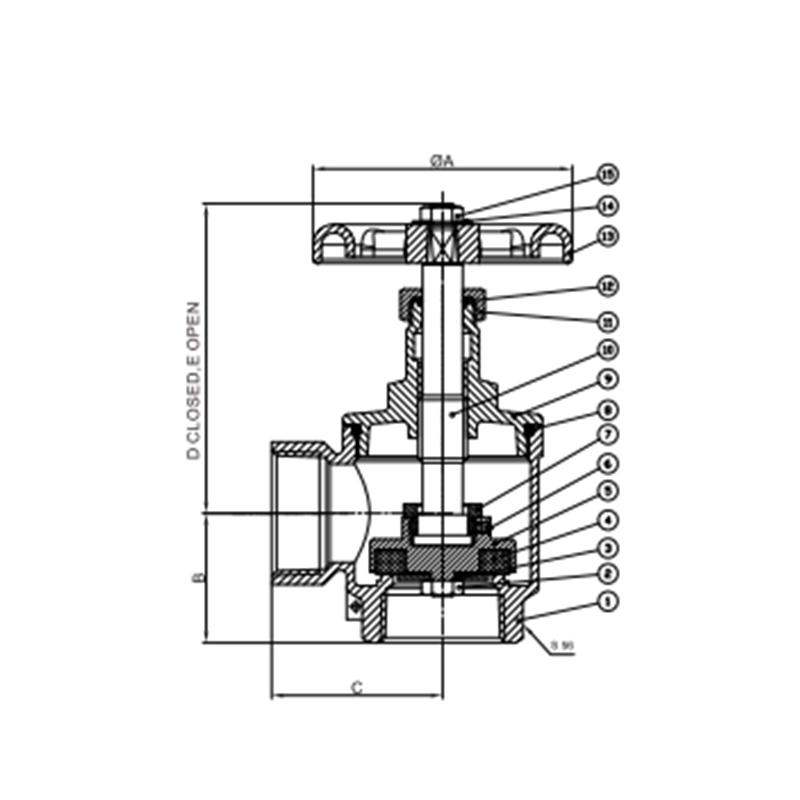

Fire Hose Angle Valve Main Parts:

- Angled Body: 90-degree ductile iron or bronze casting.

- Ball & Stem Assembly: Chrome-plated brass or stainless steel ball with through-hole.

- Quick-Open Handle: Lever for quarter-turn operation with padlock provision.

- Inlet Connection (Female): Female pipe thread (e.g., NPT) to connect to the standpipe.

- Outlet Connection (Female): Female fire hose thread (e.g., NST) to receive the male end of a fire hose.

- Automatic Drain Port: A small hole/channel in the valve body cavity to drain water when closed, preventing freeze damage.

- Seats & Seals: Resilient EPDM seals.

Role, Characteristics, and Application Scenarios of ANGLE HOSE VALVE F&F in Pipelines

Functions in Pipelines:

- Hose Station Control: Provides the primary on/off control for a fire hose line connected to a standpipe system.

- Flow Regulation: Allows firefighters to quickly start and stop water flow to the attached hose.

- System Isolation: Isolates the hose line from the standpipe main for maintenance.

- Freeze Protection: The automatic drain empties the valve body when closed.

Fire Valves Operational Features:

- Quarter-Turn Operation: Fast, full-open or full-close action via a lever.

- Dual Female Connections: Female pipe thread (inlet) + Female hose thread (outlet).

- Automatic Drain: Standard feature for cold climates.

- Pressure Rating: Typically 175 psi (12 bar) or higher for fire service.

ANGLE HOSE VALVE F&F Standards: Materials, Design, and Connections

Brass Valves Material Standards:

- Body: ASTM A536 (Ductile Iron) with epoxy coating, or ASTM B62 (Bronze).

- Internals (Ball, Stem): ASTM A276 Type 316 Stainless Steel or chrome-plated brass.

- Seats/Seals: EPDM (standard).

- Design & Performance Standards:UL 668 / FM 1311: The mandatory standard for Fire Department Hose Valves in North America.

- NFPA 14: Standard for the Installation of Standpipe and Hose Systems (governs installation).

- Hydrostatic Test Pressure: Minimum 2x working pressure (e.g., 350 psi for a 175 psi valve).

Connection Standards:

- Inlet (Female): NPT (National Pipe Tapered) thread per ANSI/ASME B1.20.1. Common sizes: 1½", 2", 2½".

- Outlet (Female): NST (National Standard Thread) or NH (National Hose) fire hose thread per NFPA 1963. Common size: 1½".

- Critical: The female hose thread (F.NST) must match the male thread on the fire hose coupling.

How to Select ANGLE HOSE VALVE F&F

Purchasing Guide:

Define Specifications:

- Size: Inlet/Outlet size (e.g., 2" NPT Inlet x 1½" NST Outlet).

- Pressure Rating: Match system design (e.g., 175 PSI WP).

- Material: Ductile Iron with epoxy coat is standard for durability.

- End Connections: Confirm F&F (Female x Female).

Verify Certifications:

- Non-negotiable: UL Listed (UL 668) or FM Approved (FM 1311). Request the listing card.

- Ensure it meets local fire code (IFC, NFPA 14).

Supplier Selection:

- Source from authorized fire protection distributors or direct from manufacturers.

- Compare brands (e.g., Potter, Metraflex, Viking) for price, availability, and accessory kits (e.g., with hose, nozzle).

- Request a submittal sheet for approval.

Pre-Shipment Inspection for Export ANGLE HOSE VALVE F&F and Key Considerations

Inspection Checklist:

ANGLE HOSE VALVE F&F Material List

.png)

.png)