Manual Wafer Butterfly Valve D71X

Manual Wafer Butterfly Valve D71X Purpose

This Wafer Butterfly Valves is used as a cutoff and adjusting equipment for the various water supply and drainage pipelines in building chemical, medicine, textile, ship and other industries.

Manual Wafer Butterfly Valve D71X Main part materials

| Valve stem | SS410/Stainless steel |

| Butterfly disc

|

Ductile lron Stainless steel/ C954

|

| Body

|

Ductile iron/Cast steel Stainless steel

|

| Sealing material

|

EPDM/ NBR/PTFE |

| Handle

|

Aluminum alloy/iron

|

Disc for DN50~DN300 could use Ductile lron with Epoxy

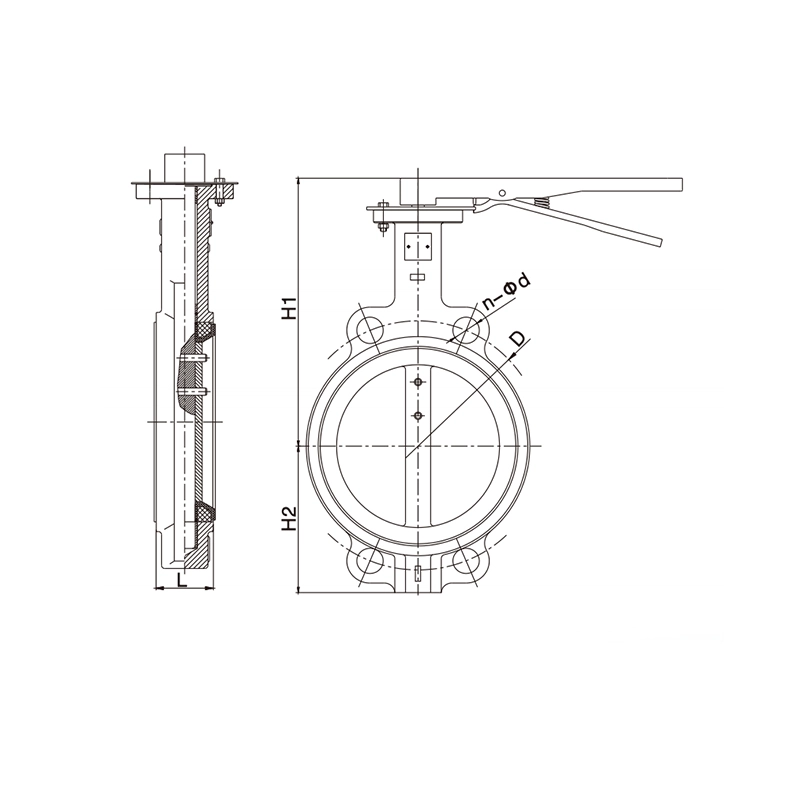

Manual Wafer Butterfly Valve D71X Main dimensions(mm)

| DN | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

| L | 33 | 43 | 46 | 46 | 52 | 56 | 56 | 60 | 68 | 78 |

| D | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 355 | 410 |

| n-Фd | 4-19 | 4-19 | 4-19 | 8-19 | 8-19 | 8-19 | 8-23 | 12-23 | 12-28 | 12-28 |

| H1 | 154 | 156 | 167 | 174 | 195 | 208 | 230 | 267 | 305 | 347 |

| H2 | 73 | 75 | 85 | 92 | 109 | 130 | 139 | 173 | 207 | 235 |

Manual Wafer Butterfly Valve D71X Definition and Components

A Manual Wafer Butterfly Valve Model D71X is a quarter-turn, lightweight isolation valve designed to be clamped between two pipeline flanges without needing through-bolts. The "D71X" designation typically indicates a specific model series, where "D" often stands for butterfly valve, "71" may refer to a lever-operated, lug-less wafer design, and "X" commonly signifies an EPDM (Ethylene Propylene Diene Monomer) rubber seat—a standard for cold water services. It provides reliable on/off control in a compact form factor.

Butterfly Valve for Water Main Parts:

- Wafer Body: The central, disc-shaped housing (typically ductile iron) that fits between flanges. It has through-holes for the pipeline's flange bolts.

- Disc (Butterfly): The circular plate (typically ductile iron or stainless steel) that rotates 90° to allow or block flow.

- Stem (Shaft): A one-piece or two-piece shaft (typically stainless steel) that connects the disc to the actuator and transmits the turning force.

- Resilient Seat (EPDM): A ring of elastomer (EPDM rubber) bonded or fitted into the body against which the disc seals to provide a bubble-tight shut-off.

- Stem Seals (O-rings/Gaskets): Prevent medium leakage along the stem.

- Manual Actuator (Lever Handle): A simple handle for 90° manual operation, often with a locking plate to secure the valve in the open or closed position.

- Bushings/Bearings: Support the stem within the body for smooth rotation.

Role, Characteristics, and Application Scenarios of Manual Wafer Butterfly Valve D71X in Pipelines

Water Valves Functions in Pipelines:

- Isolation/On-Off Service: Primary function is to start or stop fluid flow in a pipeline.

- Basic Flow Regulation: Can be used for moderate throttling, though not as precise as a globe valve.

Operational Features:

- Compact & Lightweight: The wafer design offers significant space and weight savings compared to gate valves.

- Quick Quarter-Turn Operation: 90° rotation from fully open to fully closed.

- Bidirectional Sealing: Typically provides effective sealing against flow from either direction.

- Lug-less Design: Relies on the pipeline flange bolts for structural integrity and sealing compression.

- Low Pressure Drop: When fully open, the disc presents minimal obstruction to flow.

Common Scenarios:

- HVAC Systems: Chilled and cooling water lines.

- Water & Wastewater Treatment: Pump discharge/suction, distribution lines.

- General Industrial Service: Low-pressure process water, air, and other non-aggressive media lines.

Irrigation Systems.

Manual Wafer Butterfly Valve D71X Standards: Materials, Design, and Connections

Material Standards:

- Body: Ductile Iron (ASTM A536) with epoxy coating (e.g., powder coat).

- Disc: Ductile Iron (ASTM A536) or Stainless Steel (ASTM A351 CF8/CF8M).

- Stem: Stainless Steel (AISI 416/304/316).

- Seat: EPDM (for water up to ~85°C/185°F), NBR, or Viton for other media.

- Seals: NBR or EPDM O-rings/gaskets.

Design & Performance Standards:

- API 609: The key standard for "Butterfly Valves: Double Flanged, Lug- and Wafer-Type."

- ISO 5752: Standard for "Face-to-face dimensions of metal butterfly valves."

- Pressure Rating: Common: PN10/PN16 (Class 150) for standard service.

- Leakage: Seat leakage rates often conform to ISO 5208 Rate A (zero leakage) or Rate B.

Connection Standards:

- Wafer Design: Conforms to ANSI/ASME B16.10 face-to-face dimensions and fits between ANSI/ASME B16.1 (Cast Iron) or B16.5 (Steel) flanges.

- Flange Compatibility: Designed for standard raised face (RF) or flat face (FF) flanges. The valve thickness matches the "face-to-face" dimension for the corresponding pipe size and pressure class.

How to Select Manual Wafer Butterfly Valve D71X

Purchasing Guide:Define Critical Application Parameters:

- Fluid Media & Temperature: Confirm EPDM seat compatibility (e.g., water, mild chemicals, <85°C).

- Pressure Rating: Required PN (Pressure Nominal) or Class (e.g., PN16/Class 150).

- Pipe Size & Flange Standard: Exact nominal diameter (e.g., DN150 / 6") and flange standard (e.g., ANSI B16.5 Class 150 RF).

- Material Preference: Standard is epoxy-coated ductile iron body with SS disc/stem. Upgrade if needed (e.g., full SS for corrosive environments).

Specify Technical & Quality Requirements:

- Operational Torque: For larger sizes (>8"), consider a gear operator instead of a lever.

- Standards Compliance: Specify conformance to API 609 or equivalent.

- Testing & Certification: Require a factory test certificate (shell & seat test per API 598). Request material certificates for critical parts.

Supplier Evaluation & Logistics:

Source from established valve manufacturers or specialized industrial suppliers.

Compare prices, but prioritize suppliers providing full technical data and certifications.

For large orders, request a product sample for dimensional and functional verification before full production.

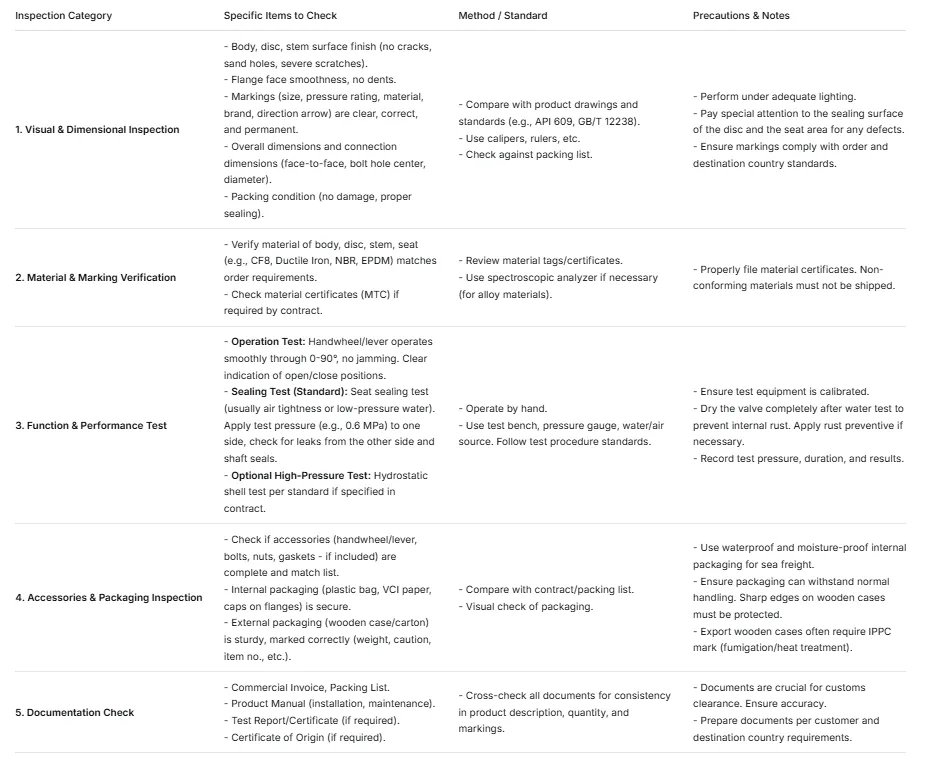

Pre-Shipment Inspection for Export Manual Wafer Butterfly Valve D71X and Key Considerations

Inspection Checklist:

.png)

.png)