ARVX Micro Air Valve

Micro Air Valve Definition and Components

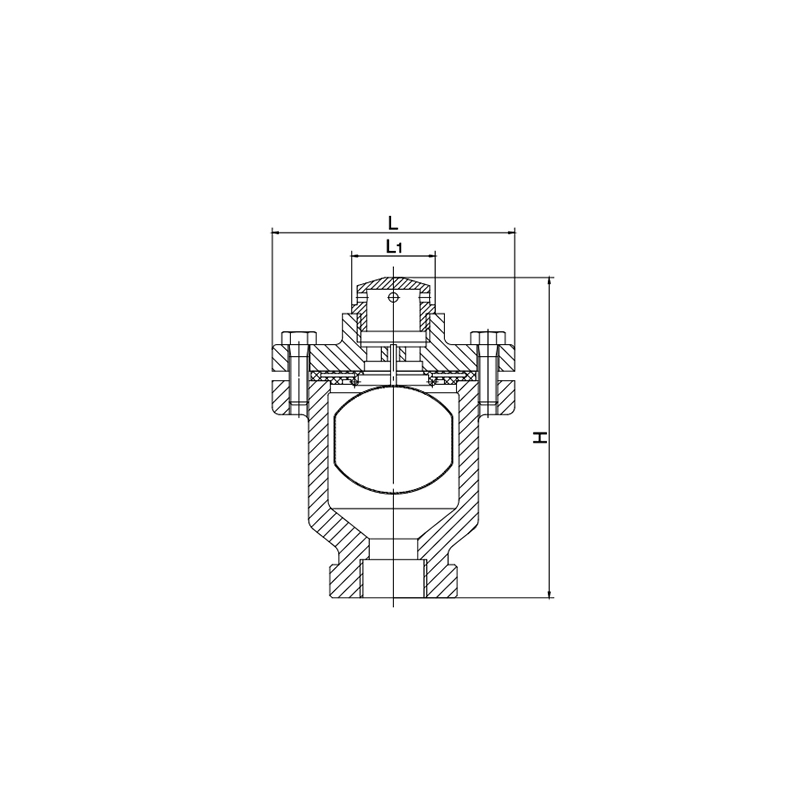

What is an ARVX Micro Air Valve and its Main Parts?

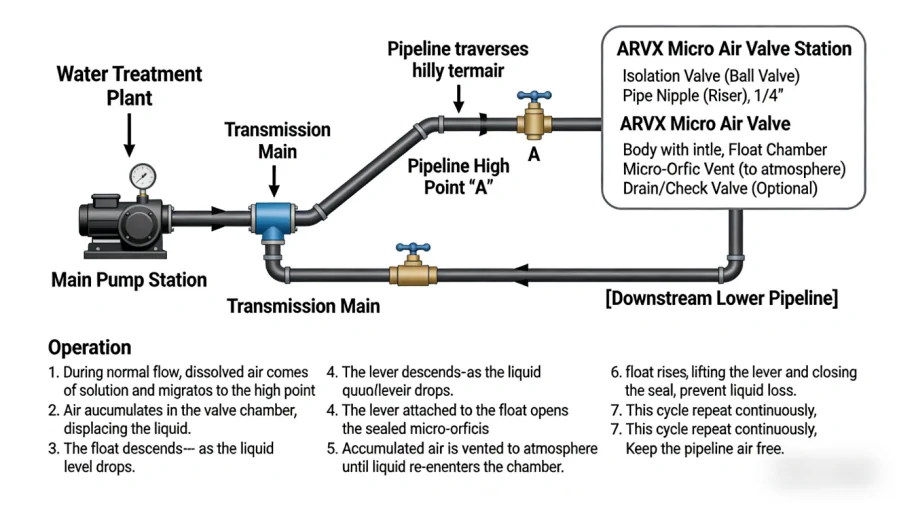

An ARVX Micro Air Valve (Automatic Air Release Valve, micro-orifice type) is a small, precision float-operated valve designed to automatically vent small pockets of accumulated air or gas from a pressurized liquid pipeline during normal operation. It handles the continuous, small-scale air release that larger air valves cannot.

Main Components:

Compact Valve Body: Typically a small, forged brass or stainless steel block with an inlet and an outlet/orifice.

Float Assembly: A small, lightweight float (usually a hollow stainless steel or polypropylene sphere) connected to a lever or direct-acting pin. It is the sensing element that rises with liquid level and falls with air accumulation.

Sealing Mechanism: A precision elastomeric seal (often a small O-ring or poppet) attached to the float lever. The seal closes the vent orifice when liquid is present

Micro-Orifice Vent: A very small discharge port (often 1/8" or smaller) to minimize liquid loss during venting. It may have a protective screen or cap.

Optional Check Valve: Some models include a tiny internal check valve to prevent liquid discharge under negative pressure conditions.

Role, Characteristics, and Application Scenarios of Micro Air Valve in Pipelines

Functions, Operational Features, and Usage Scenarios

Functions in Pipelines:

Continuous Air Release: Automatically expels small, trapped air pockets (microbubbles) that accumulate at high points during normal system operation.

Improving System Efficiency: Eliminates air locks that restrict flow, reduce pump efficiency, and increase energy consumption.

Protecting Equipment: Prevents air-related damage to pumps (cavitation), flow meters (inaccurate readings), and heat exchangers (reduced heat transfer).

Preventing Corrosion: Removing air (oxygen) from the system reduces oxidative corrosion in pipes and components

Water Valves Operational Features:

Automatic & Passive: Operates continuously without external power or control, based solely on the buoyancy of the float.

Designed for Pressurized Systems: Functions while the pipeline is under full operating pressure (unlike vacuum valves or large air/vacuum valves).

Low-Capacity, High-Frequency Venting: Excels at releasing small volumes of air continuously, not for filling or draining large volumes.

Fails Closed: The float ensures the vent seals if the chamber fills with liquid, preventing uncontrolled discharge.

Typical Usage Scenarios:

High Points in Water Mains: Installed at minor summits in municipal and industrial water pipelines where air naturally accumulates

HVAC Hydronic Systems: On top of heating/cooling coils, manifolds, and pipeline high points to ensure air-free operation for maximum efficiency.

Industrial Process Lines: On chemical, food & beverage, or cooling water lines where air pockets disrupt process control.

Pump Discharge Headers: Immediately downstream of pumps to vent air released from solution due to pressure changes.

Complement to Large Air Valves: Used in a "triple-function" air valve assembly alongside a large air/vacuum valve and a kinetic air release valve.

Micro Air Valve Standards: Materials, Design, and Connections

Air Valve for Water Material, Design, and Connection Standards

Material Standards:

Body & Cap: Forged Brass (UNS C36000/C37700), Ductile Iron (EN-GJS-400), or AISI 316 Stainless Steel for corrosive environments.

Float: Stainless Steel (AISI 304/316) or chemically resistant polypropylene.

Seals & O-rings: EPDM (standard water), NBR, or Viton (FKM) for high temps/oils.

Internal Lever/Pin: Stainless Steel.

Design & Performance Standards:

General Valve Standards: ISO 5211 (mounting interfaces may apply), EN 1074-5 (Valves for water supply - Fitness for purpose requirements).

Pressure Rating: Common ratings are PN16/PN25 (Class 150/300). Design per ASME B16.34 or equivalent.

Performance Testing: Air discharge capacity under pressure is typically characterized per manufacturer's own testing, as there is less universal standardization than for larger valves. Seat leakage tests follow EN 12266-1 or API 598.

Connection Standards:

Threaded Connections: Predominant for micro valves. BSPP (G) Threads (ISO 228-1) or NPT Threads (ASME B1.20.1). Sizes are typically ¼" (DN8), ½" (DN15), or ¾" (DN20).

Flanged Connections: Rare for micro valves, but if present, ASME B16.5 Class 150 RF.

Mounting: Often installed on a pipe nipple or a manifold block that is welded or threaded into the main pipeline.

How to Select Micro Air Valve

Procurement Process

Define Application Specifications:

Fluid: Type (water, glycol, mild chemical), temperature, cleanliness.

Operating & Design Pressure: Maximum pressure at the installation point.

Air Release Capacity Needs: While small, estimates of air ingress or release from solution can be made.

Connection Size & Type: Determine the thread standard and size of the connection point on your pipeline.

Material Compatibility: Critical for seals (EPDM vs. NBR vs. Viton) based on fluid and temperature.

Supplier Selection:

Target specialized manufacturers of air valves and pipeline accessories (e.g., ARI, DeZURIK/APCO, BERMAD, Vent-O-Mat).

Look for suppliers with a range of air valve types (micro, kinetic, large orifice) to ensure expertise.

Technical Review:

Request detailed cutaway drawings and operating principle diagrams.

Verify the pressure-temperature rating chart for the selected materials.

Confirm if a protective strainer is included or recommended upstream to protect the micro-orifice from debris.

Commercial & Logistics:

Lead times are relatively short (4-8 weeks) for standard materials

These are often purchased in bulk quantities. Confirm pricing tiers.

Spare Parts Kit: Essential to purchase a seal repair kit (O-rings, seals) for each valve or in bulk.

Support Requirements:

Request installation and maintenance bulletins.

Ensure the manufacturer provides clear guidance on installation orientation (must be installed vertically)

Pre-Shipment Inspection for Export Micro Air Valve and Key Considerations

Pre-Shipment Inspection & Export Precautions

Inspection & Testing Checklist:

Documentation Review: Verify material certificates (for body and float) and a general inspection report.

Visual & Dimensional Inspection: Check for machining defects, proper threading, and clear identification markings (pressure rating, material, brand). Ensure the vent orifice is unobstructed.

Functional Operation Test (Sample Basis - e.g., 10% of batch):

Seal Tightness (Liquid Test): Pressurize the valve in its normally closed position (simulating liquid-filled condition). Verify no leakage from the vent orifice.

Float Movement & Venting Test: Manually depress the float (simulating air accumulation) to ensure the mechanism moves freely and opens the orifice. Release to ensure it snaps back closed.

Key Precautions for Export:

Internal Cleanliness & Drying: The small orifice is prone to blockage. Valves must be internally clean, dry, and preserved with a light, compatible oil or VPI spray.

Orifice Protection: The micro-orifice vent must be protected with a plastic cap or tape to prevent ingress of dust, insects, or moisture during transit and storage.

Thread Protection: All threaded connections must be fitted with robust plastic or steel caps.

Float Chamber Securing: For some designs, the internal float should be secured or blocked (using manufacturer-supplied shipping restraints or foam) to prevent constant bouncing and wear during transport.

Packing: Due to their small size, pack multiple valves individually in polyethylene bags with desiccant inside a well-secured master carton or wooden box. Use ample cushioning to prevent abrasion.

Clear Marking: Mark packages as "AUTOMATIC AIR VALVES," "SENSITIVE COMPONENT," and "KEEP DRY." Include a packing list with quantities and part numbers in a waterproof pouch.

.png)

.png)