Water Meter Flanged End PN10 PN16

Water Meter Flanged End PN10 PN16 Feature

Removable element for facilitating installation and maintenance. long term clear reading ,inter-exchangeable parts, magnetic transmission low driving resistance. Reliable sensitive action, small pressure loss. long working life, etc.

Keep original measuring mechanism, multi-way remote out-put, nicer looking forNg21 type water meter.

| Size

(mm) |

Class | Overload

Flow |

Permanent

Flow |

Transitional

Flow |

Min Flow | Reading | Reading |

| m'/h | m' | ||||||

| 50 | A | 30 | 15 | 4.5 | 1.2 | 0.0002 | 999,999 |

| B | 3.0 | 0.45 | |||||

| 65 | A | 50 | 25 | 7.5 | 2.0 | 0.0005 | 999,999 |

| B | 5 | 0.75 | |||||

| 80 | A | 80 | 40 | 12 | 3.2 | 0.002 | 999,999 |

| B | 8.0 | 1.2 | |||||

| 100 | A | 120 | 60 | 18 | 4.8 | 0.002 | 999,999 |

| B | 12 | 1.8 | |||||

| 125 | A | 200 | 100 | 30 | 8 | 0.002 | 999,999 |

| B | 20 | 3 | |||||

| 150 | A | 300 | 150 | 45 | 12 | 0.002 | 999,999 |

| B | 30 | 4.5 | |||||

| 200 | A | 500 | 250 | 75 | 20 | 0.002 | 999,999 |

| B | 50 | 7.5 | |||||

| 250 | A | 800 | 400 | 120 | 32 | 0.002 | 999,999 |

| B | 80 | 12 | |||||

| 300 | A | 1200 | 600 | 180 | 48 | 0.02 | 999,999 |

| B | 120 | 18 | |||||

Water Meter Flanged End PN10 PN16 Definition and Components

What is a Flanged End Water Meter (PN10/PN16) and its main parts?

A Flanged End Water Meter (PN10/PN16) is a measuring instrument used to accurately measure and record the volume of water flow. It features flanged connections at both inlet and outlet, with nominal pressure ratings of PN10 (10 bar) and PN16 (16 bar). It is primarily used for trade settlement or process control of water flow in large and medium-sized industrial and commercial pipelines.

Flanged End Water Meter Main Parts:

- Body/Meter Housing: The pressure-bearing main body, typically made of cast iron, ductile iron, cast steel, or stainless steel, with flanges.

- Measuring Mechanism: The core metering unit. For mechanical meters, common types include:

- Velocity Type (Single/Multi-jet): Impeller, gear train.

- Volumetric Type (Piston/Oscillating Piston): Piston and cylinder.

- Woltmann Type (Helical Vane): Helical impeller for large flows.

- Register/Indicator: Mechanical number wheels, pointers, or electronic digital display showing totalized volume.

- Flow Conditioner/Straightener: Ensures smooth flow through the measuring element for accuracy.

- Flanged Ends: Standard-compliant flanges for connection to pipeline flanges.

- (Optional) Pulse Output/Communication Module: For remote reading or system integration.

Role, Characteristics, and Application Scenarios of Water Meter Flanged End PN10 PN16 in Pipelines

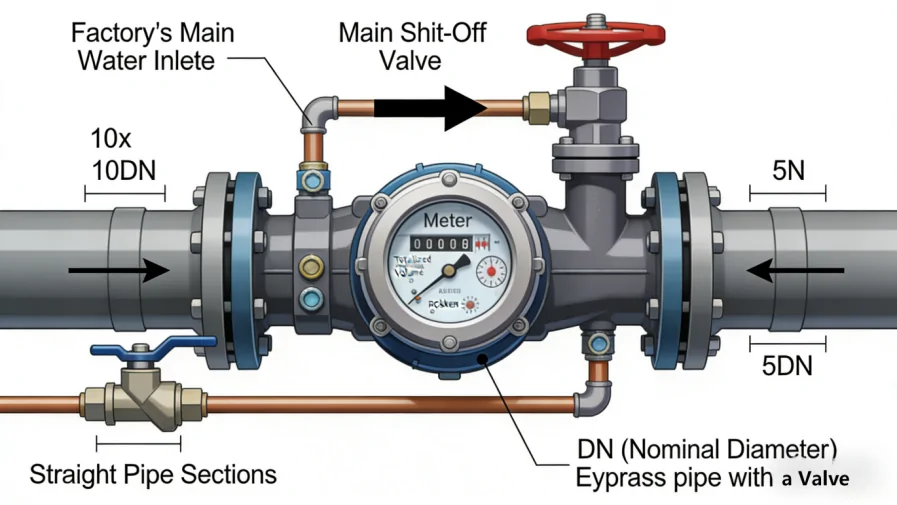

Functions, Operational Features, Usage Scenarios, and Scenario Diagram

Functions: The core function is the accurate measurement of the volume of water (cubic meters or liters) passing through a pipeline, used for trade billing, consumption monitoring, leak detection, and process control.

Operational Features:

- Continuous Totalization: Cumulative measurement of continuous flow.

- Accuracy Class: According to standards (e.g., ISO 4064), classified as Class 1, Class 2, or R series, guaranteeing measurement accuracy within specified flow rate ranges (minimum flow Q1, transitional flow Q2, permanent flow Q3, overload flow Q4).

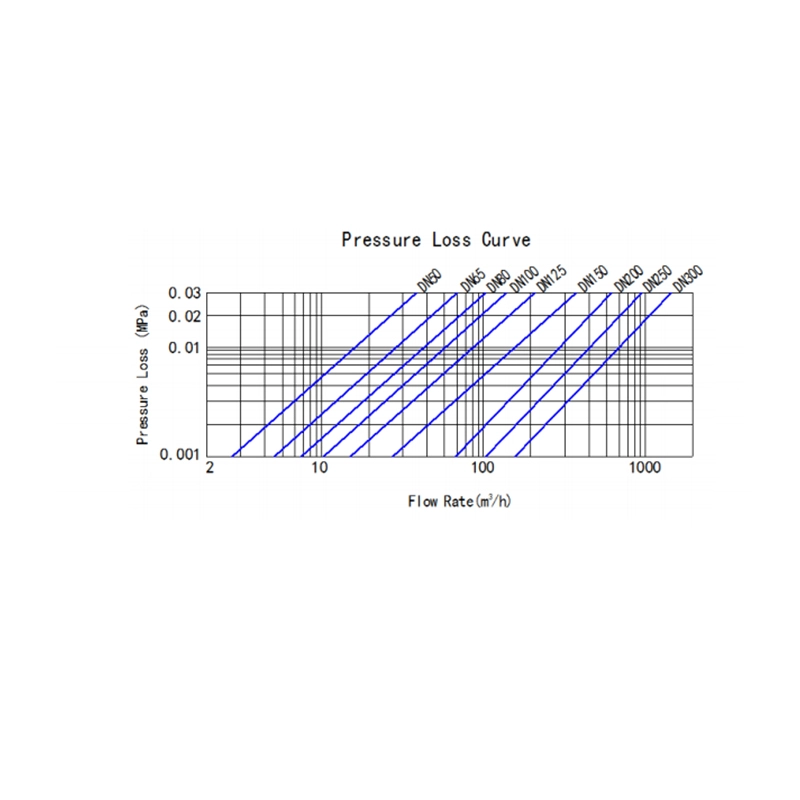

- Pressure Loss: Flow through the meter creates a pressure drop; good meters optimize design to minimize loss.

- Start Flow Rate: The minimum flow rate at which accurate measurement begins.

Usage Scenarios:

- Industrial Water Metering: Factory main inlet, process water lines, cooling water circuits.

- Commercial Building Metering: Main inlet or submetering for large offices, malls, hotels.

- District Metered Area (DMA): For water network zoning and leakage control.

- Agricultural Irrigation Metering: Large/medium irrigation channels or pump outlets.

Raw Water/Reclaimed Water Metering.

Water Meter Flanged End PN10 PN16 Standards: Materials, Design, and Connections

Material, Design, and Connection Standards

Material Standards:

- Body: Grey cast iron (ISO 185), ductile iron (ISO 1083), cast steel (ASTM A216 WCB), or stainless steel (AISI 304/316).

- Internal Components: Wear and corrosion-resistant materials like bronze, brass, stainless steel, engineering plastics.

- Design Standards:

- Metrological Performance: ISO 4064 (Water meters for cold potable water and hot water) is the key international standard.

- EU Market: Must comply with MID (Measuring Instruments Directive) and possess a valid type examination certificate.

- Others: OIML R49 is also a key reference.

Connection Standards:

- Flange Standards: Must be specified.

- EN 1092-2 (For cast iron flanges)

- EN 1092-1 (For steel flanges)

- Typically PN10 or PN16 rating, with Flat Face (FF) or Raised Face (RF).

- Sizes: Nominal diameters from DN50 (2") to DN300 (12") or larger.

How to Select Water Meter Flanged End PN10 PN16

How to Purchase

Water Meter Define Key Parameters:

- Pipe size (DN).

- Expected flow rate range (min, normal, max).

- Required accuracy class (e.g., ISO 4064 Class 2).

- Working pressure (choose PN10 or PN16).

- Medium temperature (cold or hot water).

- Need for pulse output/communication (e.g., M-Bus, Modbus).

- Legal certification requirements for the target market (e.g., MID, OIML).

Identify Qualified Suppliers: Select reputable manufacturers holding type approval certificates from authorized bodies (especially MID for EU). Check their production qualifications and quality systems.

Request Detailed Technical Documentation: Ask for:

- Accuracy curve covering the full flow range.

- Copy of the Type Approval Certificate.

- Detailed technical datasheet including pressure loss curve, start flow.

- Dimensional drawings and installation instructions.

- Compare and Place Order: Evaluate technical performance, certification completeness, price, lead time, and after-sales service. Specify all standards, certifications, and acceptance criteria in the contract.

Pre-Shipment Inspection for Export Water Meter Flanged End PN10 PN16 and Key Considerations

Pre-Export Inspection and Precautions

Inspection Protocol (Focus on Metrology):

- Visual & Marking Check: No defects on body, clear markings (size, PN, flow arrow, manufacturer, model, type approval number, year of manufacture).

- Material & Document Verification: Check material certs and validity of the Type Approval Certificate.

- Metrological Performance Sampling (Critical): Conduct accuracy tests at multiple flow points (at least Q1, Q2, Q3, Q4) per ISO 4064 in an accredited calibration lab or using certified test rigs. Results must be within the certified error limits.

- Pressure Tightness Test: Hydrostatic test to ensure no leakage from the body or connections.

- Functional Test: Check register for smooth operation, no sticking; test electronic functions if applicable.

- Packaging Inspection: Individual packaging, internal moisture-proof bag, protective caps on flanges. Sturdy export carton.

Water Valves Precautions:

- Protect Seals: Legal sealing must be applied before dispatch. Any broken seal invalidates the certification. Protect seals during transport.

- Prevent Upside Down & Impact: Mark "This Side Up", "Fragile" on packages to protect the internal mechanism.

- Moisture & Dust Proof: Special protection for electronic parts.

- Accompanying Documents: Must include: Initial Verification/Calibration Report for each meter, copy of Type Approval Certificate, User Manual, Packing List. Serial numbers on reports must match the meters.

- Compliance with Destination Regulations: Ensure all tech documents and markings comply with the importing country's metrological laws and language requirements.

Water Meter Flanged End PN10 PN16 Main dimensions(mm)

| Size | Length | Height | Connecting flange | ||

| ФD1

Outside diameter |

ФD2

Bolt circle diameter |

Connecting Bolts(n-M) | |||

| mm | |||||

| 50 | 200 | 261 | 165 | 125 | 4-M16 |

| 65 | 200 | 271 | 185 | 145 | 4-M16 |

| 80 | 225 | 279 | 200 | 160 | 8-M16 |

| 100 | 250 | 289 | 220 | 180 | 8-M16 |

| 125 | 250 | 299 | 250 | 210 | 8-M16 |

| 150 | 300 | 319 | 285 | 240 | 8-M20 |

| 200 | 350 | 346 | 340 | 295 | 8-M20(1.0MPa) |

| 12-M20(1.6MPa | |||||

| 250 | 450 | 450 | 395(1.0MPa) | 350(1.0MPa) | 12-M20(1.0MPa) |

| 405(1.6MPa) | 355(1.6MPa) | 12-M24(1.6MPa) | |||

| 300 | 500 | 478 | 445(1.0MPa) | 400(1.0MPa) | 12-M20(1.0MPa) |

| 460(1.6MPa) | 410(1.6MPa) | 12-M24(1.6MPa) | |||

.png)

.png)