API WCB Gate Valve

API WCB Gate Valve Definition and Components

What is an API WCB Gate Valve and its main parts?

An API WCB Gate Valve Meaning is a standardized industrial valve designed for demanding oil, gas, and petrochemical services. It signifies a valve that meets the stringent design, material, and testing requirements of the American Petroleum Institute (API) standards, with its primary pressure-containing parts (body and bonnet) made of ASTM A216 Grade WCB carbon steel.

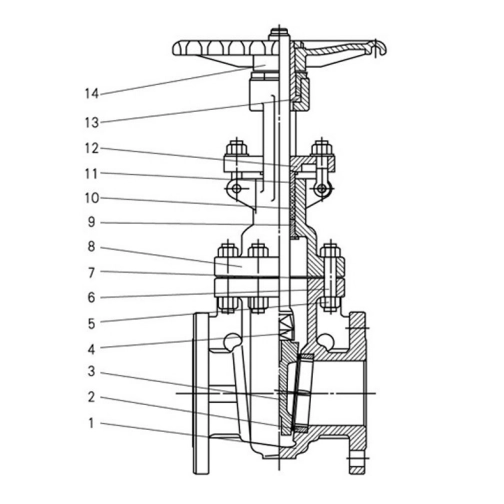

Main Parts:

Body & Bonnet: The main casting, made of ASTM A216 WCB. Connection is typically a bolted bonnet with a pressure seal or union ring for higher classes.

Gate/Wedge: The closure element. API valves often feature a flexible wedge or split wedge design to improve sealing under varying pressures and temperatures.

Stem: Usually a rising stem with outside screw and yoke (OS&Y). The stem threads are outside the valve body, protected from the flow medium.

Seat Rings: Pressed-in, welded, or threaded hardened stainless steel rings (e.g., 13% Cr or Stellite-faced) against which the gate seals.

Yoke & Yoke Sleeve/Nut: The assembly that supports the stem and connects the bonnet to the actuation mechanism.

Packing Box: Includes braided graphite or PTFE packing, a gland, and a lantern ring (for grease injection) to ensure stem sealing.

Handwheel, Gear Operator, or Actuator Mounting Pad: Manual or actuated operation. API valves commonly have a gear operator for larger sizes/higher pressures.

Flanges or Welding Ends: Connection ends conforming to ASME B16.5 (flanged) or ASME B16.25 (butt-weld).

Role, Characteristics, and Application Scenarios of API WCB Gate Valve in Pipelines

Functions, Operational Features, Usage Scenarios, and Scenario Diagram

Functions: Primarily for positive, bidirectional shut-off in pipeline services. It is designed to be either fully open or fully closed, providing minimal pressure drop when open and a tight metal-to-metal seal when closed.

Operational Features:

Robust Construction: Built for high-pressure and high-temperature hydrocarbon service.

Slow, Multi-Turn Operation: Not for quick cycling. Requires many turns of a handwheel or gear.

Fire-Safe Design: Most API gate valves are designed to API 6FA/API 607 fire-test standards, with secondary metal seals that function if soft seals burn away.

Double Block and Bleed (DBB) Capability: When closed, the valve provides two sealing surfaces, and the body cavity can be bled/bled down.

Usage Scenarios:

Wellhead & Christmas Tree Manifolds: Master valves, wing valves.

Pipeline Block Valves: Mainline isolation in transmission pipelines.

Refinery & Petrochemical Process Lines: High-pressure/temperature hydrocarbon, steam, and utility lines.

Platform/Offshore Applications: Production and export lines.

API WCB Gate Valve Standards: Materials, Design, and Connections

Material, Design, and Connection Standards

Material Standards:

Primary Material: ASTM A216 WCB for body and bonnet (-29°C to 425°C service).

Trim Materials: Defined by API trim numbers (e.g., Trim 8: Seat 13Cr, Gate 13Cr, Stem 13Cr).

Critical Components: Seats and gates are often hard-faced with Stellite (e.g., Trim 5) for abrasion/corrosion resistance.

Design Standards: The core standard is API 600 ("Bolted Bonnet Steel Gate Valves for Petroleum and Natural Gas Industries"). For pipeline valves, API 6D ("Pipeline Valves") is used. These dictate design, wall thickness, pressure-temperature ratings (based on ASME B16.34), and fire-safe requirements.

Connection Standards:

Flanged Ends: ASME B16.5 for Class 150, 300, 600, 900, etc. (RF or RTJ face common).

Butt-Weld Ends: ASME B16.25 for bevel preparation.

Face-to-Face Dimensions: Per API 600/6D or ASME B16.10.

How to Select API WCB Gate Valve

How to Purchase

Define API Specification and Service: Precisely state the required standard (e.g., API 600 or API 6D), size (NPS), pressure class (ASME Class), temperature, and fluid (e.g., sour gas requires NACE MR0175 compliance). Specify required trim number, end connection, and operation method.

Source from API-Licensed Manufacturers: Procure from manufacturers that hold the API Monogram License for the relevant standard (API 600/6D). This is a key mark of quality assurance. Verify their experience in similar projects.

Request API-Compliant Documentation: Submit a detailed inquiry requesting:

Technical datasheet with full material specification and trim details.

Certified dimensional drawings.

Proof of API Monogram license and proposed fire-test certification (API 6FA/607).

For sour service, request NACE compliance reports and Hardness Test Reports.

Pre-Shipment Inspection for Export API WCB Gate Valve and Key Considerations

Pre-Export Inspection and Precautions

Inspection Protocol (API Compliance is Mandatory):

Document Review: Verify API Monogram is correctly stamped on the valve. Check Material Test Reports (MTRs) for body, bonnet, trim components, and fasteners against the order.

Dimensional & Visual Check: Confirm face-to-face, flange dimensions, and markings. Check for proper stamping: API symbol, size, class, material, manufacturer, and unique ID.

Witness API Mandatory Testing: All tests must be per API 598 (or API 6D for pipeline valves). These include:

Shell Hydrostatic Test: At 1.5x the rated pressure.

Seat Leakage Test: Typically done with water or gas at 1.1x rated pressure. API 600/6D defines allowable leakage rates (often zero visible for liquid tests).

Backseat Test: To verify stem sealing under pressure.

(If applicable) Low-Pressure Air Seat Test: A more sensitive test often specified.

Additional Tests: For sour service, witness hardness testing on all critical components per NACE requirements.

Function Test: Operate the valve fully to ensure smooth, unrestricted movement.

Industrial valves Precautions:

Ship in the Open Position: Prevents seats from "cold welding" or being damaged under pressure.

Protect Critical Surfaces: Apply a durable, removable anti-corrosion coating on machined surfaces (stem, flange faces). Use metal or heavy-duty plastic flange protectors.

Secure Internal Parts: Ensure the gate is secured to prevent movement during transit.

Complete API Documentation Dossier: The shipment must include: Certified Test Reports signed by the inspector, MTRs, Certificate of Conformity stating API compliance, assembly drawings, and installation manual. These should be in a waterproof envelope.

Export Packing: Use reinforced, seaworthy wooden crates. Mark with "Lifting Points," "Keep Dry," and the API stamping information for identification. Valves must be securely blocked and braced inside the crate

API WCB Gate Valve Standards

| Design and Manufacture | AP1600、 API6D, JIS B2073-2083 |

| Inspection and Test | API598、 API6D, JIS B2003、 APi600 |

| End Flange dimension | ASME B16.5、 JIS B2212-2214 |

| End Flange dimension | ASME B16.47A、 MSS SP-44 |

| End Flange dimension | ASME B16.47B、 API605 |

| BW end dimension | ASME B16.25 |

| Face to face | ASME B16.10、 jisb2002 |

| Pressure-temperature ratings | ASME B16.34 |

API WCB Gate Valve Standard Material Specifications

| Parts name | Carbon Steel to ASTM |

Alloy Steel to ASTM |

Stainless Steel to ASTM | ||||||||

| 1 | Body | A216 | A352 LCВ | A217 WC1 | A217 WC6 | A217 WC9 | 217 WC5 | A351 CF8 | A351 CF8M | A351 CF3 | A351CF3M |

| 8 | Bonnet | A216WCВ | A352LCВ | A217 WC1 | A217 WC6 | A217 WC9 | 217 WC5 | A351 CF8 | A351 CF8 | A351 CF3 | A351CF3М |

| 6 | Bolts | A193 B7 | A320L7 | A193 B7 | A193 B16 | A193 B16 | A193 B16 | A193 B8 | A193 B8 | A193 B8 | A193 B8 |

| 5 | Nuts | A194 2H | A1944 | A194 2 | A194 4 | A194 4 | A194 4 | A194 8 | A194 8 | A194 8 | A194 8 |

| 11 | Gland | A182 F6a | A182F6a | A182 F6а | A182 F6а | A182 F6а | A182 F6а | A182 F304 | A182 F304 | A182 F304L | A182 F316L |

| 12 | Gland Flange | A216 WCB | A352 LCB | A217 WС1 | A217 WC6 | A217 WC9 | A217 C5 | A351 CF8 | A351 CF8 | A351 CF3 | A351 CF3M |

| 2 | Disc | A216 WCB | A352 LCВ | A217 WС1 | A217 WC6 | A217 WС9 | A217 C5 | A217 CF8 | A217 CF8 | A351 CF3 | A351 CF3М |

| 7 | Gasket | SS Spiral Wound W/graphite,or SS Spiral Wound W/PTFE, or Reinforced PTFE | |||||||||

| 10 | Packing | Braided graphite, or Die-formed graphite ring or PTFE | |||||||||

| 13 | Stem Nut | Copper alloy or A439 D2 | |||||||||

| 14 | Hand wheel | Ductile iron or Carbon steel | |||||||||

Noted: The chart above only lists out some common composition of steel gate valve parts. We may provide other different parts material composition according to the customer' s request or the actual valve working condition.

We also supply fire valve and water valves.

.png)

.png)