Flanged Silencing Check Valve HC41X

Flanged Silencing Check Valve HC41X Purpose

This Silencing Check Valve is mounted on the pump outlet and can prevent the medium from back flow and effectively eliminate both noise and water hammer in the high building water supply, fire fighting water supply and cooling circulation water systems.

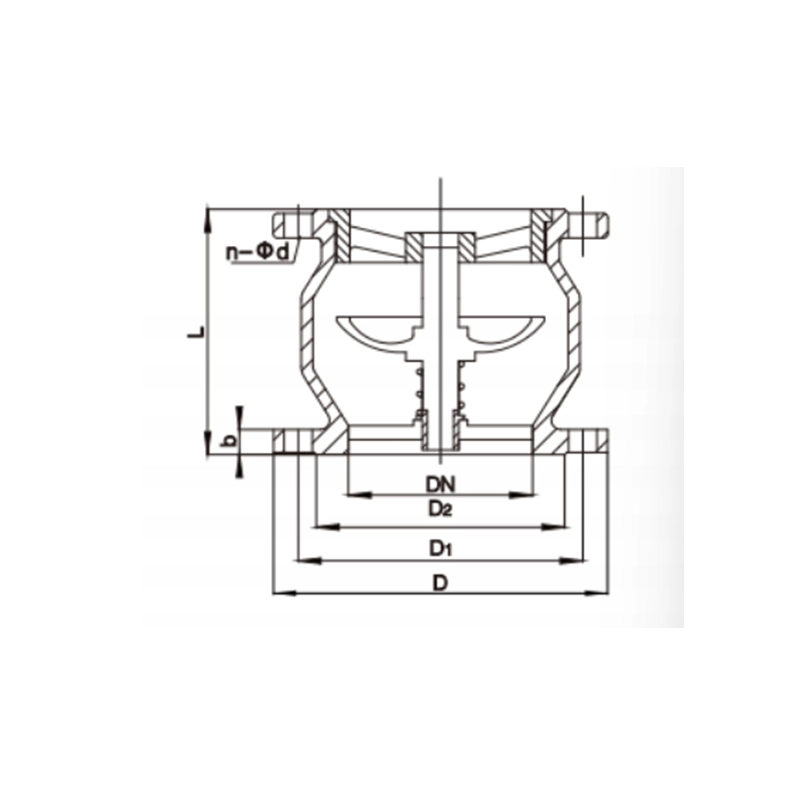

Flanged Silencing Check Valve HC41X Definition and Components

What is a HC41X Valve?

The HC41X is a Flanged, Silencing (or Silent) Check Valve. The "HC" indicates Check Valve, "4" means Flanged ends, "1" often refers to a specific structure (typically a lift or piston-type design), and "X" denotes a Resilient (rubber) seat. It is engineered to prevent the loud "slam" and destructive water hammer associated with traditional swing check valves by using a damping mechanism to ensure slow, controlled closing just before flow reversal.

Water Check Valve Main Parts:

- Valve Body: A flanged, typically Y-pattern or angle-pattern body to guide flow, made of cast iron or ductile iron.

- Piston/Disc Assembly: The closure element. It is a metal disc or piston with a resilient O-ring or seal, moving linearly within a guide sleeve or cylinder.

- Damping Mechanism: The core component. This consists of a dashpot—a sealed cylinder and piston—filled with a viscous fluid (e.g., silicone oil). It controls the closing speed.

- Spring: A coil spring that assists in initiating closure as flow slows.

- Guide Sleeve/Bushing: Ensures the piston moves in a straight line for proper sealing.

- Resilient Seat: An EPDM or NBR seal providing bubble-tight shut-off.

Role, Characteristics, and Application Scenarios of Flanged Silencing Check Valve HC41X in Pipelines

Pipeline Functions:

- Backflow Prevention: Primary function as a check valve.

- Water Hammer & Noise Elimination: Its defining function is to dramatically reduce or eliminate the pressure surge and loud bang caused by rapid valve closure.

Operational Features:

- Controlled, Slow Closure: The dashpot mechanism meters the closing speed, allowing the disc to close gently just as forward flow reaches zero velocity.

- Quiet Operation: Eliminates the metal-on-metal slam, hence "silent" or "silencing."

- Can Be Installed in Any Orientation: Unlike swing checks, its axial movement allows vertical or horizontal installation.

- Higher Cost & Maintenance: More complex than a standard check valve. The dashpot requires occasional fluid check/replacement.

Water Valves Application Scenarios:

- Used in pumping systems where water hammer poses a risk to pipeline integrity or where noise is unacceptable.

- Building HVAC Systems: On pump discharge in tall buildings to prevent hammer in risers.

- Industrial Pumping Stations: Protecting long pipelines from destructive pressure surges.

- Water & Wastewater Plants: In critical pump discharge lines to safeguard piping and fittings.

- Central Heating/Cooling Systems: In large commercial or district energy systems.

Scenario Diagram (Text Description):

In a high-rise building's chilled water system, a vertical inline pump sends water up 30 stories. A standard check valve would slam shut powerfully when the pump stops, shaking the pipes. Instead, an HC41X Silencing Check Valve is installed on the pump discharge. When the pump stops, flow decelerates. The spring starts to close the piston, but the dashpot filled with silicone oil critically dampens the motion. The piston takes 3-5 seconds to close gently, sealing just as forward flow ceases. This prevents any sudden reversal and associated pressure spike, eliminating noise and protecting the system from water hammer damage, all while performing its essential backflow prevention duty.

Flanged Silencing Check Valve HC41X Standards: Materials, Design, and Connections

Material Standards:

- Body/Bonnet: Cast Iron (ASTM A126), Ductile Iron (ASTM A536).

- Piston/Disc: Bronze or Stainless Steel.

- Spring: Stainless Steel.

- Seals: EPDM, NBR.

Design Standards:

- API 594: Check Valves: Flanged, Lug, Wafer, and Butt-welding. (Governs check valve design).

- ASME B16.34: Valve Pressure-Temperature Ratings.

- MSS SP-71: Cast Iron Check Valves.

- AWWA C508: Swing-Check Valves (a related waterworks standard).

- Connection Standards:

- Flanges: ASME B16.1 Class 125/250 or EN 1092-2 PN10/16.

How to Select Flanged Silencing Check Valve HC41X

Key Steps:

- Identify the Need for Silencing: Justify the purchase based on a water hammer analysis, noise restrictions, or protection of sensitive equipment.

- Specify Closure Speed/Time: This is the critical parameter. Consult with the manufacturer to determine the required closing time (e.g., 3-10 seconds) based on your system's pressure, pipe length, and fluid to effectively cushion the surge.

- Confirm Orientation: While versatile, confirm your installation orientation (vertical flow-up, vertical flow-down, horizontal) with the supplier as it can affect spring selection.

- Discuss Dashpot Maintenance: Inquire about the dashpot fluid type, expected service interval, and procedure for checking/refilling it.

Pre-Shipment Inspection for Export Flanged Silencing Check Valve HC41X and Key Considerations

Inspection Checklist:

- Functional Damping Test (MANDATORY): This is not a standard pressure test. The valve must be tested for its controlled closing action. Simulate flow stoppage and verify the piston closes slowly and smoothly over several seconds, not instantaneously.

- Pressure Testing: Standard shell test and seat leakage test per API 598 (zero leakage for resilient seat).

- Dashpot Integrity: Check for any external leakage of the damping fluid from the dashpot cylinder.

- Spring Action: Verify the piston returns freely when inverted.

Export Precautions:

- Ship in Closed Position: Secure the piston in the closed position to prevent constant bouncing during transit.

- Protect the Dashpot: Clearly mark the valve to indicate the presence of the sealed dashpot assembly. Avoid impacts to this area.

- Preservation: Ensure the valve is drained and dry internally. For carbon steel components, apply a vapor corrosion inhibitor.

- Documentation: Require detailed installation, operation, and dashpot maintenance instructions to be included in the shipping documents.

.png)

.png)