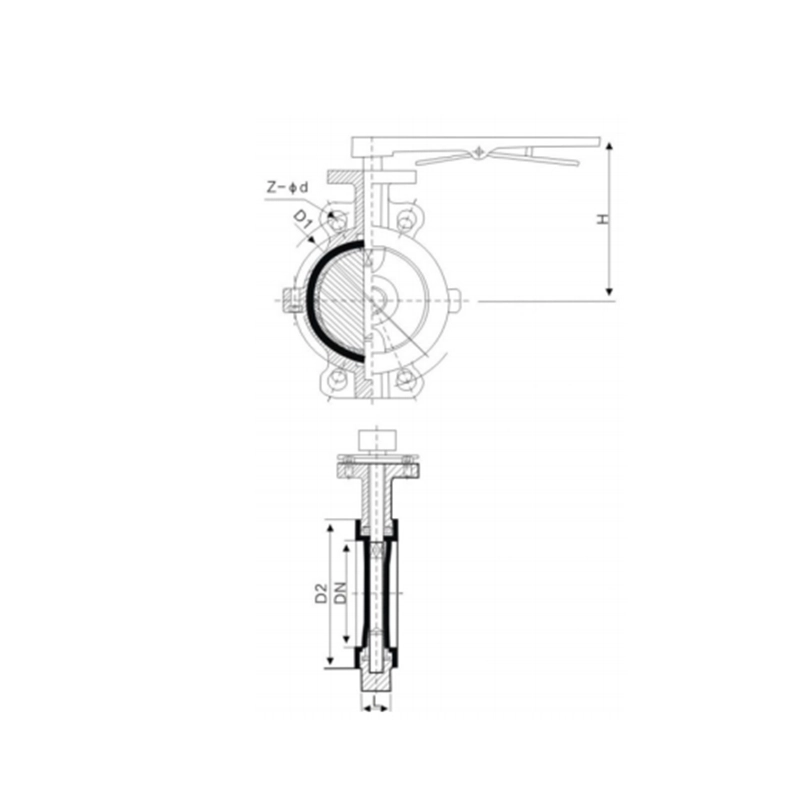

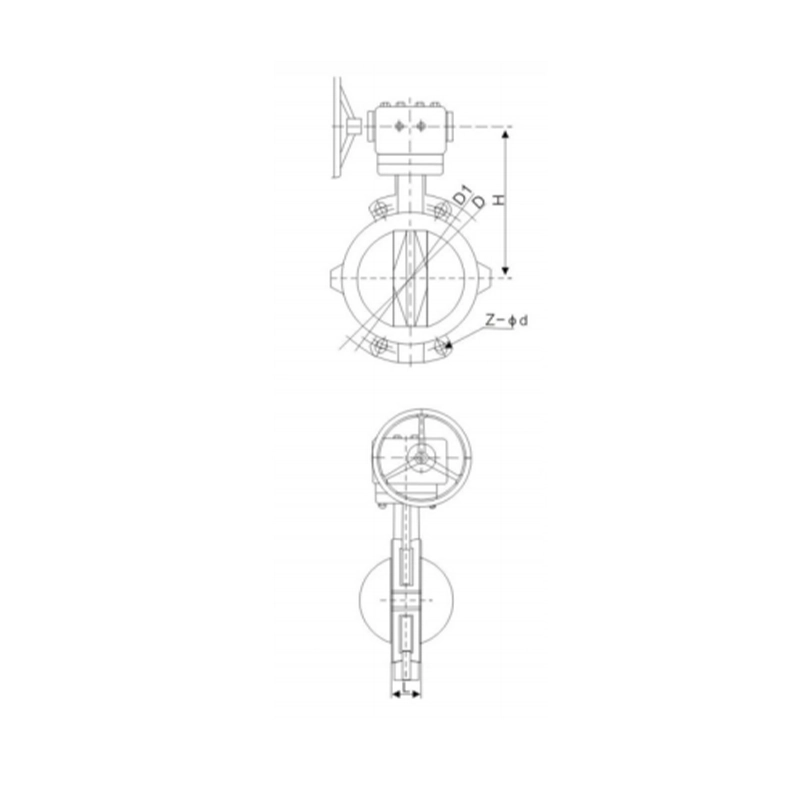

Full Lined Wafer type Butterfly Valve D371F/D71F

Full Lined Wafer type Butterfly Valve D371F/D71F Purpose

This Wafer Type Butterfly Valves is used as a cutoff and adjusting equipment. For the various water supply and drainage pipelines in building. chemical, medicine, textile, ship and other industries

Full Lined Wafer type Butterfly Valve D371F/D71F Definition and Components

A Full Lined Wafer Type Butterfly Valve (Models D371F/D71F) is a specialized quarter-turn valve designed for handling highly corrosive, abrasive, or ultra-pure fluids. The key feature is a continuous, seamless lining of fluoropolymer (typically PTFE, FEP, or PFA) that completely encapsulates the fire protection valve's internal wetted surfaces—the body bore, the disc, and often the stem sealing area. This creates an inert barrier between the aggressive process media and the metallic valve structure.

- D371F: Gear-operated version for larger sizes or higher torque requirements.

- D71F: Lever-operated version for smaller sizes and manual operation.

Full Lined Wafer type Butterfly Valve D371F/D71F Main Parts:

- Carbon Steel or Ductile Iron Body Shell: Provides structural strength.

- Full Fluoropolymer Lining (PTFE/FEP/PFA): The continuous, seamless lining covering all internal surfaces.

- Lined Disc: The flow control element, also fully encapsulated in the lining material.

- Stem: Usually made of high-grade stainless steel (e.g., 316SS) or a compatible exotic alloy.

- Secondary Stem Seal (Stuffing Box): Often includes additional PTFE/V-ring packing to ensure stem sealing integrity.

- Actuator: Manual lever (D71F) or worm gear operator (D371F).

Role, Characteristics, and Application Scenarios of Full Lined Wafer type Butterfly Valve D371F/D71F in Pipelines

Water Supply Valves Functions in Pipelines:

- Corrosion/Erosion Isolation: To reliably isolate or regulate extremely corrosive acids, bases, solvents, or abrasive slurries without contaminating the media or damaging the valve.

- Process Purity Maintenance: To handle ultra-pure or sensitive fluids (e.g., in pharmaceuticals, food) without risk of metallic ion contamination.

- Bidirectional Sealing: Provides tight shut-off against pressure from either direction.

Operational Features:

- Exceptional Chemical Resistance: Compatible with a vast range of aggressive chemicals, depending on the lining material (PTFE for broadest resistance).

- Non-Stick, Smooth Surface: Prevents scaling, build-up, and facilitates easy cleaning (CIP/SIP compatible).

- Temperature Limits: Defined by the lining (e.g., PTFE: -20°C to 180°C).

- Pressure Limitations: Lower than unlined valves due to the mechanical properties of the liner (e.g., typically up to PN10/16 or Class 150).

- Fire-Safe Option: Some models offer metal seat backups for fire-safe certification (e.g., API 607).Common Usage Scenarios:

- Chemical & Petrochemical Plants: For sulfuric acid, hydrochloric acid, caustic soda, chlorine, and solvent lines.

- Pharmaceutical & Biotechnology: In purified water (PW), water for injection (WFI), and process lines requiring high purity.

- Pulp & Paper Industry: Handling bleaching chemicals (chlorine dioxide, hypochlorite) and aggressive pulping liquors.

- Metal Pickling & Surface Treatment: For hydrochloric, nitric, and hydrofluoric acid lines.

- Wastewater & Off-Gas Treatment: Handling corrosive scrubber solutions and emissions.

Full Lined Wafer type Butterfly Valve D371F/D71F Standards: Materials, Design, and Connections

Butterfly Valve for Water Material Standards:

- Body Shell: Carbon Steel (ASTM A216 WCB) or Ductile Iron (ASTM A536).

- Lining Material: PTFE (Polytetrafluoroethylene) per ASTM D4894/4895, FEP (Fluorinated Ethylene Propylene), or PFA (Perfluoroalkoxy).

- Disc Core: Carbon Steel or CF8M Stainless Steel, fully encapsulated.

- Stem: Stainless Steel AISI 316/316L or Alloy 20 for severe service.

Design & Performance Standards:

- API 608: "Metal Ball Valves - Flanged, Threaded, and Welding End" - Often referenced for design principles of lined valves.

- ISO 16136: "Industrial valves - Thermoplastic valves for corrosive fluids" provides guidance.

- Fire-Safe Design: API 607 / ISO 10497 for fire testing of soft-seated valves (if specified).

- Face-to-Face: ISO 5752 or API 609.

- Pressure Rating: Typically PN10/16 (Class 150). Manufacturer's rating must be followed due to liner limitations.

Connection Standards:

- Wafer Design: Conforms to standard wafer dimensions to fit between ANSIB16.5 or EN 1092-1 flanges.

- Flange Compatibility: Liner extends to form a full-face gasket, sealing against the flange faces. Requires correct flange surface finish (smooth) and bolt torque to avoid crushing the liner.

How to Select Full Lined Wafer type Butterfly Valve D371F/D71F

Define the Aggressive Service Conditions:

- Exact Fluid Composition & Concentration: This is the single most important factor dictating liner material choice (PTFE, FEP, PFA).

- Temperature & Pressure Cycle: Must fall within the safe operating graph (SOG) of the chosen liner.

- Pipe Size & Flange Standard: e.g., DN80, ANSI Class 150 RF.

- Actuation Requirement: Specify lever (D71F) or gear operator (D371F) based on size and required torque.

Specify Technical Requirements in Detail:

- Lining Material & Thickness: Specify (e.g., "Virgin PTFE, 3mm thick").

- Lining Process: Request a seamless, bubble-free lining applied using isostatic molding or rotational sintering for best integrity.

- Testing & Certification: Mandate spark testing (high-voltage pinhole detection) of the liner at 10kV/mm or higher. Require full material traceability and a factory test certificate per API 598.

- Special Needs: Indicate if fire-safe design, CIP/SIP capability, or 3-A Sanitary certification is required.

Supplier Qualification:

- Source from manufacturers specializing in lined equipment with a proven track record.

- Require detailed technical submittals, including liner chemical resistance charts and pressure-temperature ratings.

- For critical applications, consider a pre-production meeting and request witnessed factory acceptance tests (FAT).

Pre-Shipment Inspection for Export Full Lined Wafer type Butterfly Valve D371F/D71F and Key Considerations

Lining Integrity Inspection (CRITICAL):

- Visual: Inspect the liner for any cracks, bubbles, delamination, or discoloration. Surface must be smooth and uniform.

- Spark Test Verification: Review the factory spark test report to confirm the entire wetted surface was tested with no failures. If possible, witness a spot re-test.

- Dimensional Check: Verify liner thickness at multiple points using an ultrasonic gauge.

Mechanical & Functional Check:

- Operate the valve through its full cycle. Movement must be smooth; the disc must not scrape the liner.

- Check that the liner protrudes evenly to form the gasket face.

- Verify all markings (size, material, pressure rating, lining type) are correct.

Packaging Inspection:

- The valve must be packed with the disc in a slightly open position (5-10°) to avoid permanent set in the liner.

- The liner faces must be protected by smooth, rigid plastic or cardboard covers taped on at the edges—never use adhesive directly on the liner surface.

- The package must include desiccant bags to prevent moisture condensation on the cold liner.

Full Lined Wafer type Butterfly Valve D371F/D71F Main Dimensions(mm)

| DN | L | D | D1 | D2 | z-Фd | H | Weight | D | D1 | D2 | z-Фd | H | Weigh |

| 40 | 33 | 150 | 110 | 85 | 4-18 | 140 | 2.3 | 150 | 110 | 85 | 4-18 | 140 | 5 |

| 50 | 43 | 165 | 125 | 100 | 4-18 | 140 | 2.7 | 165 | 125 | 200 | 4-18 | 140 | 5.8 |

| 65 | 46 | 180 | 145 | 120 | 4-18 | 150 | 3.5 | 180 | 145 | 120 | 4-18 | 150 | 6.7 |

| 80 | 46 | 200 | 160 | 135 | 4-18 | 165 | 4.7 | 200 | 160 | 135 | 8-18 | 165 | 7.5 |

| 100 | 52 | 220 | 180 | 155 | 4-18 | 180 | 6.5 | 220 | 180 | 155 | 8-18 | 180 | 8.8 |

| 125 | 56 | 250 | 210 | 185 | 4-18 | 200 | 8 | 250 | 210 | 185 | 8-18 | 200 | 11 |

| 150 | 56 | 285 | 240 | 210 | 8-23 | 220 | 10 | 285 | 240 | 210 | 8-23 | 220 | 15 |

| 200 | 60 | 340 | 295 | 265 | 8-23 | 270 | 17 | 340 | 395 | 265 | 12-27 | 270 | 24 |

| 250 | 68 | 395 | 350 | 320 | 12-23 | 320 | - | 406 | 355 | 320 | 12-27 | 320 | 34 |

| 300 | 78 | 445 | 400 | 370 | 12-23 | 330 | - | 460 | 410 | 370 | 12-27 | 330 | 44 |

| 350 | 78 | 505 | 460 | 430 | 16-23 | 385 | - | 520 | 470 | 430 | 16-27 | 385 | 86 |

| 400 | 102 | 565 | 515 | 480 | 16-23 | 430 | - | 580 | 525 | 480 | 16-30 | 430 | 128 |

| 450 | 114 | 615 | 565 | 560 | 20-26 | 480 | - | 640 | 585 | 550 | 20-30 | 480 | 159 |

| 500 | 127 | 670 | 620 | 580 | 20-26 | 540 | - | 715 | 650 | 610 | 20-33 | 540 | 190 |

| 600 | 154 | 780 | 725 | 680 | 20-30 | 610 | - | 840 | 770 | 720 | 20-36 | 610 | 235 |

| 700 | 165 | 895 | 840 | 795 | 24-33 | 650 | - | 910 | 840 | 759 | 24-36 | 650 | 335 |

| 800 | 190 | 1015 | 950 | 900 | 24-33 | 710 | - | 1025 | 950 | 900 | 24-39 | 740 | 425 |

| 900 | 203 | 1115 | 1050 | 1050 | 28-33 | 780 | - | 1125 | 1050 | 1000 | 28-39 | 780 | 500 |

| 1000 | 213 | 1230 | 1160 | 1115 | 28-36 | 900 | - | 1255 | 1170 | 1110 | 28-42 | 900 | 705 |

| 1200 | 254 | 1455 | 1380 | 1380 | 32-39 | 1050 | - | 1485 | 1390 | 1330 | 32-48 | 1050 | 880 |

Note:1. Other specifications and flange standards are available upon request.

- Design and specifications are subject to change without prior notice.

.png)

.png)