Full Stainless Steel Wafer type Butterfly Valve SSD71F

Full Stainless Steel Wafer type Butterfly Valve SSD71F Purpose

This valve is used as a cutoff and adjusting equipment for the various water supply and drainage pipelines in building chemical,medicine, textile, ship and other industries.

Full Stainless Steel Wafer type Butterfly Valve SSD71F Definition and Components

A Full Stainless Steel Wafer Type Butterfly Valve Model SSD71F is a corrosion-resistant, quarter-turn isolation valve where all primary wetted components are constructed from solid stainless steel. The "SSD71F" designation typically breaks down as: "SS" for Stainless Steel, "D" for Butterfly Valve, "71" for Wafer Body with Lever Operation, and "F" often indicating a PTFE (or similar) Seat. It's designed for demanding services where corrosion resistance, hygiene, and mechanical strength are critical.

Main Parts:

- Body (Wafer Style): Made entirely from AISI 316 or 304 Stainless Steel, machined to fit between two pipeline flanges.

- Disc: A solid stainless steel disc (often 316SS), precision-machined and sometimes coated or treated for enhanced wear/sealing.

- Stem: A one-piece or two-piece stainless steel shaft (typically 316 or 17-4PH SS) for high strength and corrosion resistance.

- PTFE Seat/Ring: A resilient, chemically inert seat (Polytetrafluoroethylene) that the disc seals against, often housed in a groove on the body or disc.

- Stem Seals: Multiple sets of PTFE or reinforced PTFE V-rings or chevron packing to ensure a leak-proof stem seal.

- Bushings/Bearings: Stainless steel or composite bearings supporting the stem.

- Lever Handle: A manual stainless steel or coated steel lever for 90° operation, often with a locking plate.

Role, Characteristics, and Application Scenarios of Full Stainless Steel Wafer type Butterfly Valve SSD71F in Pipelines

Fire fighting valves types Functions in Pipelines:

- Corrosion-Resistant Isolation: To reliably start/stop the flow of moderately to highly corrosive fluids, brines, seawater, and chemicals.

- Hygienic/Sanitary Process Control: To maintain cleanliness in processes where product purity is essential, as stainless steel is non-porous and easily cleaned.

- High-Purity Service: To handle ultra-pure water, solvents, or process fluids without risk of metallic contamination (no leaching from coatings or linings).

- Bidirectional Shut-off: Provides bubble-tight sealing in both flow directions.

Fire protection water supply Operational Features:

- Full SS Construction: Excellent resistance to pitting, crevice corrosion, and oxidation, especially with 316 SS (Mo-added).

- Wide Temperature Range: Can handle higher temperatures than plastic-lined valves (limited by the PTFE seat, typically up to 200°C).

- Robust & Durable: Solid metal construction offers good mechanical strength and resistance to water hammer/pressure surges.

- Smooth Bore: Minimizes pressure drop and prevents entrapment of particles.

- Cleanability: Suitable for Clean-in-Place (CIP) and Sterilize-in-Place (SIP) processes in hygienic industries.

Full Stainless Steel Wafer type Butterfly Valve SSD71F Standards: Materials, Design, and Connections

Material Standards:

- Body & Disc: ASTM A351 CF8M (equivalent to AISI 316) or CF8 (AISI 304). Low-carbon grades (316L/304L) are preferred for welded assemblies to prevent carbide precipitation.

- Stem: AISI 316/316L, 17-4PH (precipitation hardening) or Monel for specific services.

- Seat: Virgin PTFE per FDA/ USP Class VI regulations for hygienic service, or Reinforced PTFE (RPTFE) for better wear.

- Seals & Gaskets: PTFE, FEP, or EPDM.

Design & Performance Standards:

- API 609: The key standard for design and testing of wafer butterfly valves.

- ISO 5752: Face-to-face dimensions.

- ASME B16.34: Valves - Flanged, Threaded, and Welding End (for pressure-temperature ratings).

- Hygienic Standards: 3-A Sanitary Standards or EHEDG guidelines may apply for food/pharma variants.

- Pressure Rating: Typically PN16/PN25 (Class 150). Full vacuum rating is common.

Connection Standards:

- Wafer Design: Conforms to standard wafer dimensions per ISO 5752 or API 609, fitting between ANSI B16.5, EN 1092-1, or JIS B2220 flanges.

- Flange Compatibility: Suitable for Raised Face (RF) flanges. The valve may have a slight recess to accommodate a standard flat gasket.

How to Select Full Stainless Steel Wafer type Butterfly Valve SSD71F

Define the Service Environment Precisely:

- Fluid Composition: Specify all chemicals, concentrations, and chlorides present. This determines if 304 or 316 SS is required.

- Temperature & Pressure Cycles: Important for seat material selection and pressure class.

- Hygienic/Cleanliness Requirements: Specify if Electropolishing (Ra < 0.8 µm), passivation per ASTM A967, or 3-A certification is needed.

- Pipe Size & Flange Standard: e.g., DN100, ANSI Class 150 RF.

Specify Detailed Material and Quality Requirements:

- Exact Material Grades: Demand 316L Stainless Steel for body, disc, and stem. Request Material Test Reports (MTRs).

- Seat Material: Specify PTFE grade (e.g., FDA-compliant, glass-filled for wear).

- Testing & Documentation: Require API 598 test certificate. For critical services, specify helium leak test for seat leakage.

- Surface Finish: Specify interior bore finish (e.g., "32 Ra max, electropolished").

Supplier Qualification:

- Source from manufacturers with expertise in corrosion-resistant alloys (CRAs) and proven quality control for stainless steel castings/machining.

- Review supplier's capability to provide proper documentation (MTRs, certs).

- For large projects, consider source inspection or witnessed Factory Acceptance Testing (FAT).

Pre-Shipment Inspection for Export Full Stainless Steel Wafer type Butterfly Valve SSD71F and Key Considerations

Material & Surface Inspection (CRITICAL):

- Material Marking: Verify "CF8M" or "316" casting marks on body and disc.

- Surface Finish: Check for smooth, polished interior bore. Look for any signs of pitting, crevices, or welding defects. Verify electropolishing if specified.

- Passivation: The surface should be uniformly clean; a passivation certificate should be provided.

- Spark Test: Use a handheld alloy analyzer (PMI gun) to spot-check material chemistry if MTRs are in doubt.

Mechanical & Functional Check:

- Operate the lever through full 90° travel. Movement must be smooth without sticking.

- Check for proper alignment of the disc in the bore; there should be no scraping.

- Verify all markings on the nameplate (Size, PN, Material, Model).

Packaging Inspection:

- Cleanliness: The valve must be degreased, clean, and dry internally. It should be bagged in VCI (Vapor Corrosion Inhibitor) plastic.

- Protection: All machined faces must be protected by cardboard or plastic covers taped to the valve body, not the flange faces.

- Position: The disc should be in a partially open position (~10°).

Full Stainless Steel Wafer type Butterfly Valve SSD71F Main part materials

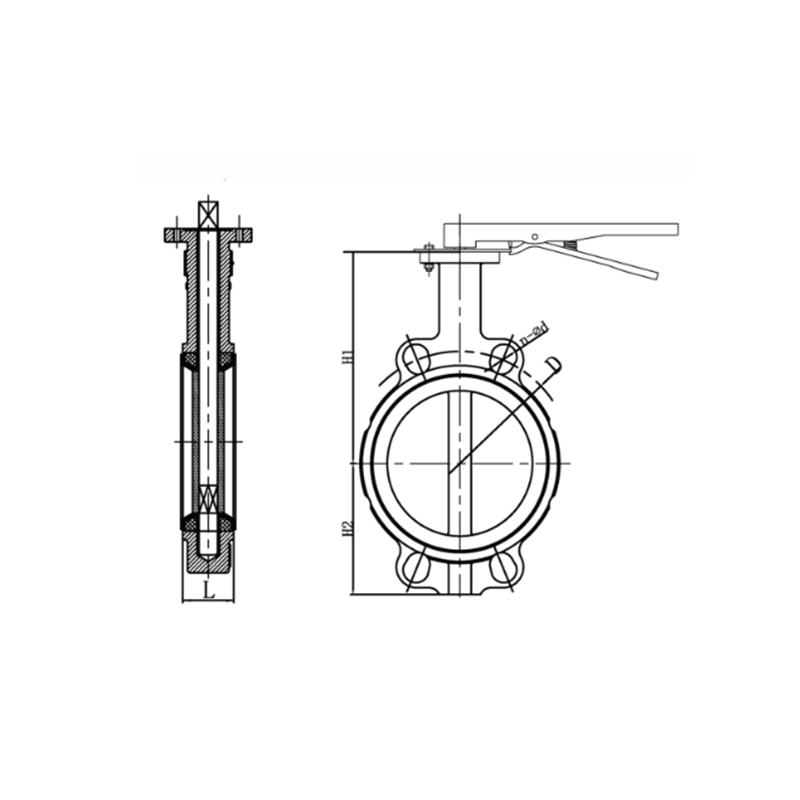

| DN | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

| L | 33 | 43 | 46 | 46 | 52 | 56 | 56 | 60 | 68 | 78 |

| D | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 355 | 410 |

| n-Фd | 4-19 | 4-19 | 4-19 | 8-19 | 8-19 | 8-19 | 8-23 | 12-23 | 12-28 | 12-28 |

| H1 | 154 | 156 | 167 | 174 | 195 | 208 | 230 | 267 | 305 | 347 |

| H2 | 73 | 75 | 85 | 92 | 109 | 130 | 139 | 173 | 207 | 235 |

Note:1. Other specifications and flange standards are available upon request.

- Design and specifications are subject to change without prior notice.

.png)

.png)