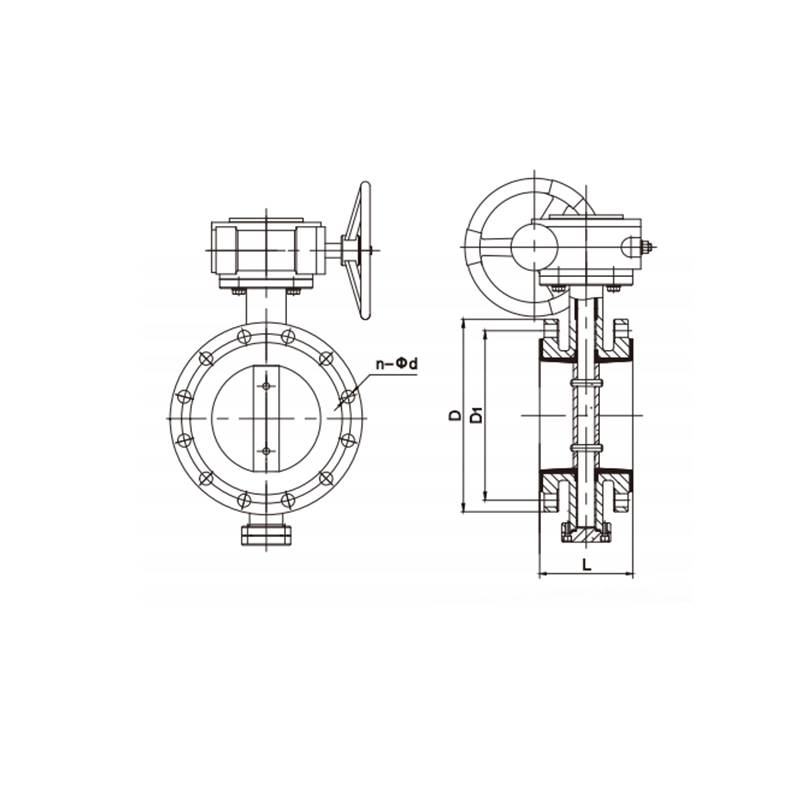

Manual Flanged Butterfly Valve D341X

Manual Flanged Butterfly Valve D341X Purpose

This product is used for the water supply and drainage system in tap water, sewage, building, chemical. industries, usually used as an open-close equipment.

Manual Flanged Butterfly Valve D341X Definition and Components

D341X is a Chinese valve designation code where:

- D: Butterfly Valve

- 3: Driving mode - Manual

- 4: Connection type - Flanged

- 1: Structural type - Single or Center-line design

- X: Seal material - Rubber

This is a manual gear-operated flanged butterfly valve with rubber sealing, widely used in water supply, drainage, and industrial pipelines.

Fire protection water supply Main Components:

| Component | Material/Type | Function |

| 1. Valve Body | Ductile Iron, Cast Steel, Stainless Steel | Main pressure-containing part, connects to pipeline |

| 2. Disc | Ductile Iron with coating/Nickel-plated/Stainless Steel | Controls flow by rotating 90° |

| 3. Stem | Stainless Steel (2Cr13/304/316) | Transmits torque from actuator to disc |

| 4. Seat | EPDM/NBR/Viton Rubber | Provides bubble-tight seal against disc |

| 5. Gear Operator | Worm-gear mechanism | Reduces operating torque, allows easier manual operation |

| 6. Body Seals | EPDM/O-ring | Prevents external leakage |

| 7. Flanges | Integrated/bolted | Connection to pipeline according to standard dimensions |

Role, Characteristics, and Application Scenarios of Manual Flanged Butterfly Valve D341X in Pipelines

Butterfly Valve for Water Functions in Pipelines:

- Isolation/Shut-off: Complete on/off control

- Flow Regulation: Throttling capability (though not precision control)

- Bidirectional Sealing: Effective sealing in both flow directions

- Low Pressure Drop: Minimal flow resistance when fully open

Operational Features:

| Feature | Description |

| Quick Operation | 90° rotation from fully open to closed |

| Low Torque Requirement | Gear operator reduces manual effort |

| Compact Design | Requires less space compared to gate valves |

| Bubble-tight Seal | Rubber seat ensures zero leakage |

| Maintenance-friendly | Often has replaceable seats without removing valve from line |

| Cost-effective | Lower cost than equivalent gate/ball valves |

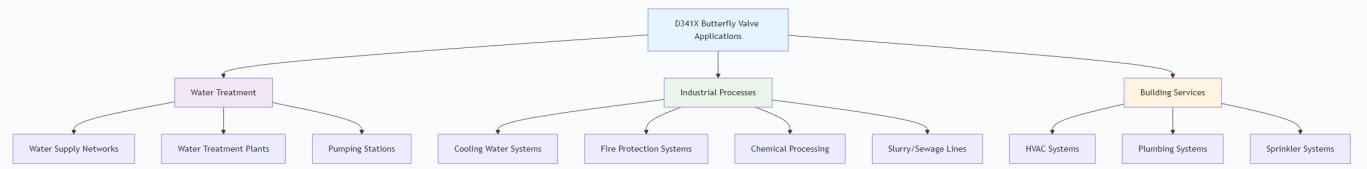

Application Scenarios:

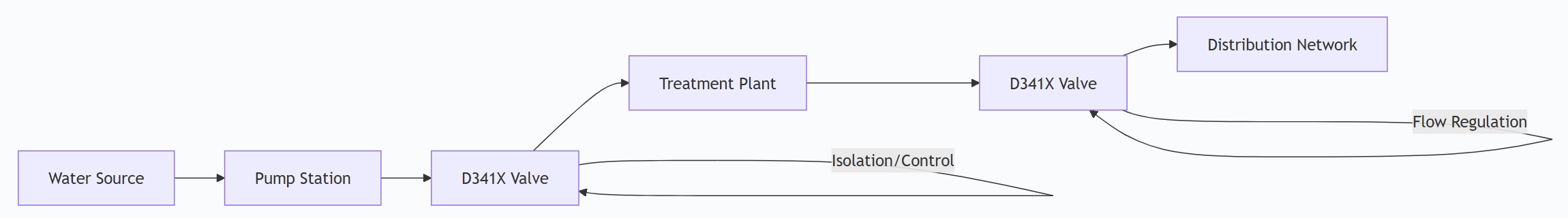

Typical Working Scenario:

Manual Flanged Butterfly Valve D341X Standards: Materials, Design, and Connections

Material Standards:

Body/Disc:

- GB/T 12226 (Cast Iron)

- GB/T 12227 (Ductile Iron)

- ASTM A216 WCB (Cast Carbon Steel)

- ASTM A351 CF8/CF8M (Stainless Steel)

Stem:

- GB/T 1220 (Stainless Steel)

- ASTM A276 304/316

Seat:

- EPDM: ASTM D2000

- NBR: ASTM D2000

- Viton: ASTM D2000

Design Standards:

- API 609: Butterfly Valves

- EN 593: Industrial Valves - Metallic butterfly valves

- GB/T 12238: National Standard for Butterfly Valves

- MSS SP-67: Butterfly Valves

- ISO 10631: General purpose metallic butterfly valves

Connection Standards:

Flange Standards:

- GB/T 17241 (Chinese National)

- ANSI B16.5 (ASME American)

- EN 1092-1 (European)

- JIS B2220 (Japanese)

Face-to-Face:

- ISO 5752 (Basic series)

- API 609

- EN 558

Pressure-Temperature Ratings:

- PN10, PN16, PN25 (EN standard)

- Class 150, Class 300 (ASME standard)

- Operating Temperature: -10°C to +120°C (depending on seat material)

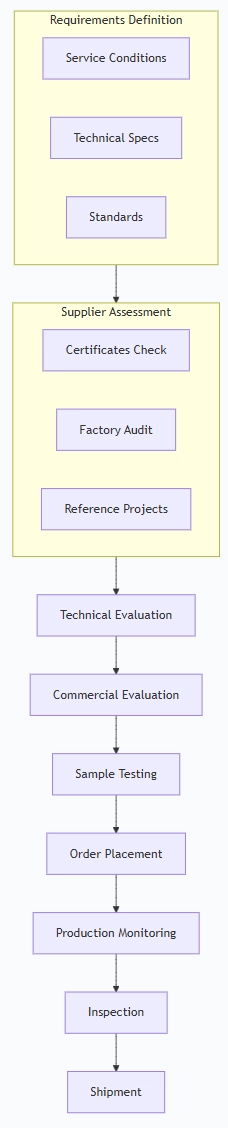

How to Select Manual Flanged Butterfly Valve D341X

Step-by-Step Purchasing Process:

Key Technical Specifications to Specify:

- Size Range: DN50 to DN1200 (2" to 48")

- Pressure Rating: PN10/16 or Class 150

- Temperature Range: Based on medium

- Seat Material: EPDM for water, NBR for oil, Viton for chemicals

- Body Material: Ductile Iron (common), Carbon Steel (high temp/pressure)

- Stem Material: Minimum 2Cr13, preferably 304/316SS

- Flange Standard: Specify exact drilling pattern

- Operation: Gear ratio, number of turns, handwheel size

- Paint/Coating: Internal epoxy, external paint per ISO 12944

- Testing Requirements: API 598/ISO 5208 standards

Fire Protection System Supplier Evaluation Checklist:

✅ ISO 9001 certification

✅ API 607/6FA fire-safe certification (if required)

✅ CE/PED certification for European market

✅ Material certificates (3.1/3.2 per EN 10204)

✅ Previous export experience

✅ Testing facility availability

✅ Production capacity and lead time

Pre-Shipment Inspection for Export Manual Flanged Butterfly Valve D341X and Key Considerations

Inspection Checklist:

| Category | Check Points | Acceptance Criteria | Tools/Methods |

| Documentation | 1. Packing List | Complete, accurate, certified | Visual check |

| 2. Material Certs | |||

| 3. Test Reports | |||

| 4. Manuals | |||

| Visual Inspection | 1. Surface finish | No defects, proper coating, protected faces | Visual, coating thickness gauge |

| 2. Markings | |||

| 3. Coating quality | |||

| 4. Flange face protection | |||

| Dimensional Check | 1. Face-to-face | Within tolerance per drawings | Calipers, tape, templates |

| 2. Flange dimensions | |||

| 3. Bolt hole alignment | |||

| 4. Handwheel size | |||

| Mechanical Operation | 1. Smooth operation | Smooth, accurate, no binding | Manual operation |

| 2. Full travel 90°<>3. Position indicator | |||

| 4. No excessive play | |||

| Pressure Testing | 1. Shell test | No visible leakage, stable pressure | Test pump, gauges, duration timer |

| 2. Seat test | |||

| 3. Duration | |||

| 4. Pressure gauge calibration | |||

| Packaging | 1. Wooden crate | Secure, weather-protected, marked | Visual check |

| 2. Internal protection | |||

| 3. Proper blocking | |||

| 4. Shipping marks |

Critical Testing Requirements:

Shell Test (High Pressure Test):

- Test pressure: 1.5 × PN rating

- Medium: Water (or air for small valves)

- Duration: Minimum 15 minutes (API 598)

- Acceptance: No visible leakage, no structural deformation

Seat Test (Low Pressure Test):

- Test pressure: 1.1 × PN rating or 6 bar minimum

- Medium: Air or water (air preferred for bubble detection)

- Duration: Minimum 15 seconds per side (bidirectional valves)

- Acceptance: Zero leakage allowed for soft-seated valves

Special Tests (if specified):

- Fire Test: API 607/API 6FA

- Cryogenic Test: For low-temperature service

- NACE MR0175: For sour service

- Fugitive Emission: ISO 15848 for stem seal leakage

Precautions for Export Shipment:

Documentation:

- Ensure all documents are in English

- Include country-specific certificates (GOST for Russia, PED for EU, etc.)

- Provide original material certificates (3.1/3.2)

Packaging:

- Use export-grade wooden crates (ISPM-15 certified for phytosanitary treatment)

- Apply heavy-duty rust preventive (VCI paper or desiccants)

- Protect flange faces with plastic/metal covers

- Secure valve disc in slightly open position to prevent seat damage

Marking:

- Permanent marking per MSS SP-25

- Shipping marks visible on multiple crate sides

- Hazard labels if applicable

- Center of gravity indication for large valves

Inspection Timing:

- Conduct inspection after final painting but before packaging

- Witness pressure tests whenever possible

- Take dated photographs during inspection

- Verify random sampling for batch orders

Common Defects to Watch For:

- Porous casting (foundry defects)

- Improper welding repairs (if any)

- Incorrect flange drilling

- Improper seat installation

- Inadequate coating thickness

- Incorrect gear ratio or turns count

Environmental Considerations:

- Ensure compliance with RoHS/REACH for European markets

- Check for restricted substances per destination country

- Proper disposal of test water (especially for valves in chemical service)

Quality Records:

- Maintain traceability from material heat number to final valve

- Keep calibration certificates of test equipment

- Document all non-conformities and corrective actions

- Provide inspection release note before shipment

Manual Flanged Butterfly Valve D341X Main dimensions(mm)

Note:1. Other specifications and flange standards are available upon request.

- Design and specifications are subject to change without prior notice.

.png)

.png)