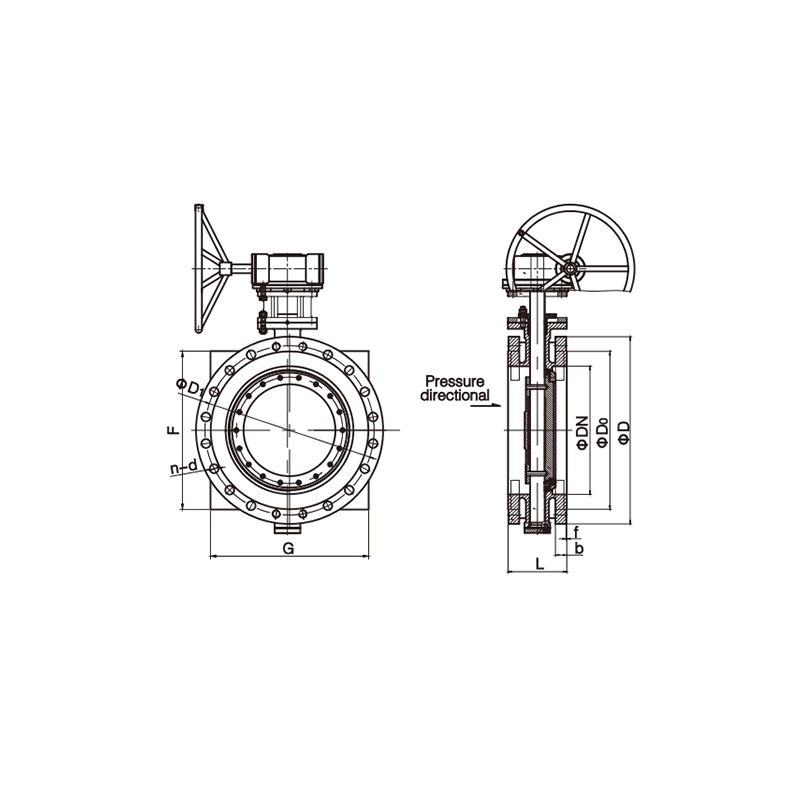

Resilient Seat Double Three Eccentric Flanged Butterfly Valve D342X D343X

Resilient Seat Double Three Eccentric Flanged Butterfly Valve Purpose

The butterfly valve is suitable for use in metallurgy, chemical power, municipal engineering and medium such as water, oi land air pipeline, as cutting fluid and adjust medium flow rate, etc.

Resilient Seat Double Three Eccentric Flanged Butterfly Valve Definition and Components

1.1 Product Definition

D342X/D343X are resilient seat double/triple eccentric flanged butterfly valves, representing advanced technical upgrades over standard concentric butterfly valves (D341X) for demanding applications.

D342X - Double Eccentric Butterfly Valve:

- First Offset: Stem axis offset from disc centerline

- Second Offset: Stem axis offset from valve/pipe centerline

- Result: Disc lifts away from seat during initial opening, minimizing friction and wear

D343X - Triple Eccentric Butterfly Valve:

- Third Offset: Seat cone angle offset (conical seat design)

- Revolutionary Advantage: Zero contact between disc and seat throughout entire operation until final closure

- Sealing Principle: "The tighter it closes, the better it seals" through wedge action

Resilient Seat: Typically refers to composite structures where a metallic seat body incorporates elastic sealing elements (PTFE, reinforced graphite, special alloys) or features laminated metal/graphite designs. This provides superior temperature/pressure resistance compared to rubber seats and often includes fire-safe functionality.

1.2 Main Components

| Component | Material/Description | Primary Function |

| Valve Body | Carbon Steel (WCB), Stainless Steel (CF8/CF8M), Special Alloys | Pressure-containing housing with standard flanges |

| Disc | Same as body + surface treatment (Ni-plating, hard coating) | Eccentric rotating element for flow control |

| Stem | High-strength alloy steel (17-4PH, XM-19) or corrosion-resistant alloys | Torque transmission with precise offset positioning |

| Resilient Seat Assembly | Composite: Metal carrier + PTFE/Graphite/PEEK inserts or laminated metal-graphite | Provides bubble-tight sealing with fire-safe capability |

| Bearing System | Self-lubricating composite (steel-PTFE/bronze) or needle bearings | Supports stem, ensures smooth low-torque operation |

| Sealing System | • Stem seals: Multi-level packing/spring-energized seals | Prevents external leakage at dynamic/static joints |

| • Body gasket: Spiral-wound or metal-jacketed | ||

| Actuation System | Worm gear operator (manual) with position indicator; Optional: pneumatic/electric/hydraulic actuators | Provides mechanical advantage for operation |

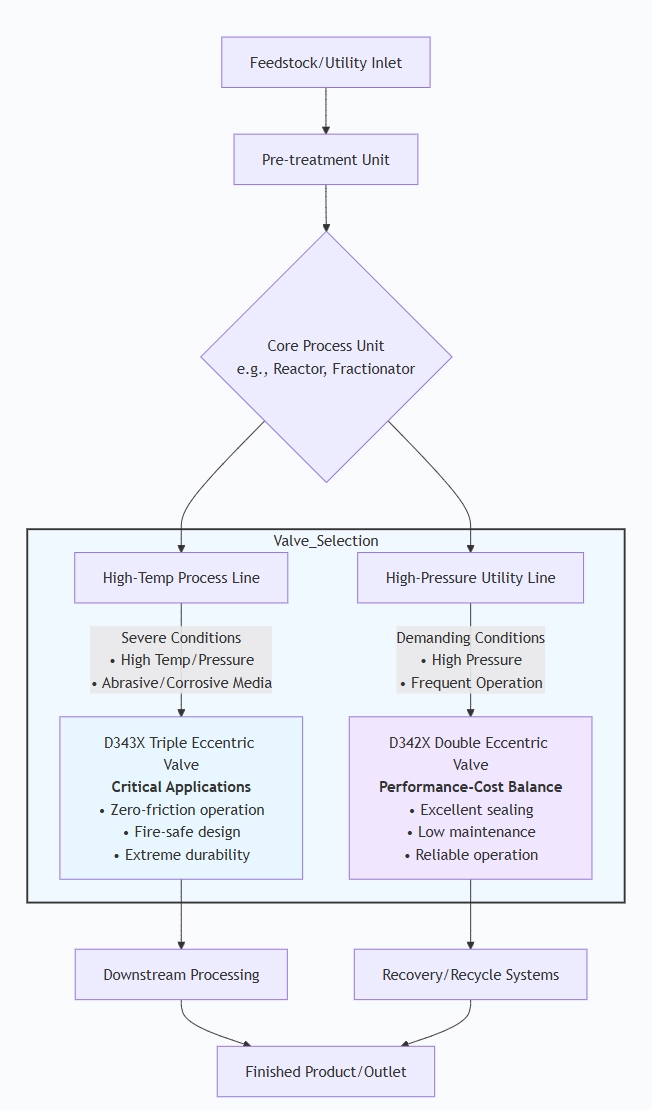

Role, Characteristics, and Application Scenarios of Resilient Seat Double Three Eccentric Flanged Butterfly Valve in Pipelines

2.1 Pipeline Functions

Bidirectional Isolation: Near-zero leakage shutoff in both flow directions

Flow Regulation: Improved flow characteristics for throttling applications

Safety Shutdown: Critical isolation point for Emergency Shutdown (ESD) systems

Severe Service Handling: Suitable for abrasive, high-temperature, high-pressure, or corrosive media

2.2 Operational Features Comparison

| Feature | D342X (Double Eccentric) | D343X (Triple Eccentric) |

| Friction During Operation | Minimal contact | Zero contact |

| Operating Torque | Low and consistent | Extremely low, equal opening/closing torque |

| Sealing Performance | Uni/bidirectional resilient sealing (up to Class VI) | Bidirectional metal/resilient composite, approaching zero leakage |

| Service Life | Long (>10× standard butterfly valves) | Exceptionally long (hundreds of thousands of cycles) |

| Temperature Range | Up to 300°C (dependent on seat materials) | Up to 550°C+ (with all-metal designs) |

| Fire-Safe Capability | Optional with special seats | Standard/inherent with metal secondary sealing |

| Cost Profile | Medium-high | High |

2.3 Application Scenario Diagram

Fire protection water supply Typical Industries & Services:

- Oil & Gas: Pipeline transmission, refinery process lines, offshore platforms

- Power Generation: Main steam, feedwater, cooling water systems

- Petrochemical: Catalytic cracking units, ethylene plants, high-pressure reactors

- Marine: Shipboard systems, ballast, fuel lines

- LNG: Cryogenic applications (special designs required)

- Water Treatment: High-pressure pump discharge, backwash systems

Resilient Seat Double Three Eccentric Flanged Butterfly Valve Standards: Materials, Design, and Connections

3.1 Material Standards

| Component | Common Standards | Typical Materials |

| Body & Disc | ASTM A216, ASTM A351, ASTM A995, EN 10213 | WCB, LCB, CF8, CF8M, Duplex 2205/2507 |

| Stem | ASTM A564, ASTM A182, NACE MR0175 | 17-4PH, 316SS, Inconel 718, Duplex steels |

| Seat Materials | ASTM D4894, ASTM D7542, FDA 21 CFR 177 | PTFE, RPTFE, PEEK, Flexible Graphite, Metal Alloys |

| Bearings & Bushings | ASTM B505, ISO 4379 | Bronze C93200, PTFE composites, reinforced polymers |

3.2 Design & Performance Standards

| Standard | Title | Key Application |

| API 609 | Butterfly Valves: Double Flanged, Lug- and Wafer-Type | Primary design/manufacturing standard |

| API 607 | Fire Test for Soft-Seated Quarter-Turn Valves | Fire-safe certification |

| ISO 17292 | Metal butterfly valves for petroleum, petrochemical and related industries | International design standard |

| MSS SP-68 | High Pressure Butterfly Valves with Offset Design | High-pressure applications |

| ISO 15848 | Industrial valves - Measurement, test and qualification of fugitive emissions | Low-emission requirements |

3.3 Connection Standards

| Flange Standard | Pressure Classes | Face Types | Common Regions |

| ASME B16.5 | Class 150, 300, 600 | RF, RTJ | North America, Middle East, Asia |

| EN 1092-1 | PN10, PN16, PN25, PN40 | Type 11, 12, 13 | Europe, International projects |

| JIS B2220 | 5K, 10K, 16K, 20K | RF | Japan, Southeast Asia |

| ASME B16.47 | Class 75-900 | RF, RTJ | Large diameter pipelines |

Face-to-Face Dimensions: ISO 5752 Series 20 (aligned with API 609)

How to Select Resilient Seat Double Three Eccentric Flanged Butterfly Valve

4.1 Technical Specification Development

Develop a comprehensive Valve Data Sheet including:

Butterfly Valve for Water Service Conditions:

- Fluid composition (including abrasives/corrosives)

- Operating pressure/temperature (min/max/design)

- Cycle frequency (continuous/intermittent)

- Ambient conditions (offshore, cryogenic, etc.)

Design Requirements:

- Pressure class (ANSI/PN) and design code

- Temperature rating

- Leakage class (ANSI/FCI 70-2 Class VI, zero leakage)

- Fire-safe requirements (API 607/6FA)

- Fugitive emission compliance (ISO 15848, TA-Luft)

- NACE MR0175 for sour service

- Special requirements: X-ray, PMI, NDE

Material Selection Matrix:

| Service Condition | Body Material | Seat Material | Stem Material |

| General Water/Oil | WCB | PTFE/EPDM | 304SS |

| Seawater/Chemical | 316SS/Alloy 20 | RPTFE/PEEK | 316SS/Alloy K500 |

| High-Temp Steam | WC6/WC9 | Flexible Graphite/Alloy | 17-4PH/Inconel |

| Cryogenic (LNG) | LCB/304SS | PTFE/Graphite | 304SS/316SS |

| Sour Service | LCB with special trim | RPTFE/Graphite | NACE-compliant alloys |

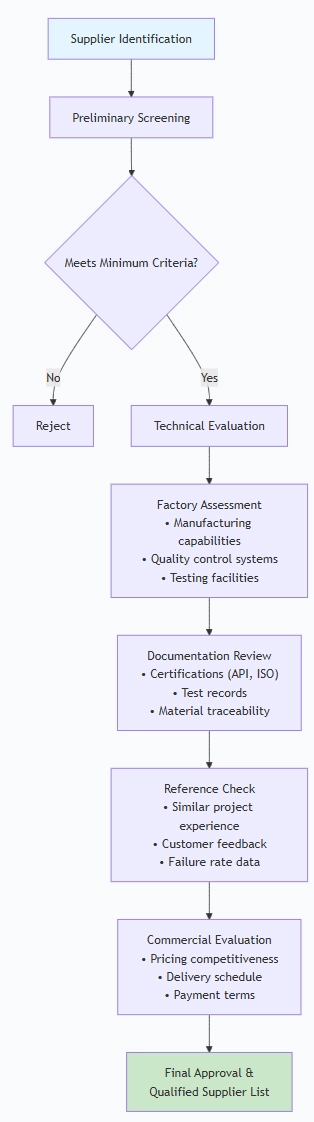

4.2 Supplier Qualification Process

Key Fire Protection System Supplier Certifications to Verify:

✅ API 609 Monogram License

✅ API 607/6FA Fire Test Certificates (for specific models)

✅ ISO 9001:2015 Quality Management

✅ CE/PED for European market

✅ NACE MR0175/ISO 15156 compliance

✅ Environmental certifications (ISO 14001)

4.3 Ordering Documentation

Ensure purchase orders include:

- Detailed technical specifications

- Reference to all applicable standards

- Inspection and test requirements (ITP)

- Witness/hold points for critical inspections

- Packaging and marking requirements

- Documentation deliverables list

Pre-Shipment Inspection for Export Resilient Seat Double Three Eccentric Flanged Butterfly Valve and Key Considerations

5.1 Comprehensive Inspection Protocol

Stage 1: Documentation Review

- Material Test Certificates (EN 10204 3.1/3.2)

- Original API/ISO certificates

- Non-Destructive Examination reports

- Heat treatment charts

- Final assembly and test reports

- Paint/coating certificates

Stage 2: Visual & Dimensional Inspection

| Check Point | Acceptance Criteria | Measurement Tools |

| Surface Finish | Free of defects, smooth finish | Visual, surface comparator |

| Markings | Permanent, legible, per MSS SP-25 | Visual |

| Flange Dimensions | Within tolerance per ASME B16.5/EN 1092-1 | Calipers, micrometers, templates |

| Face-to-Face | Within ISO 5752/API 609 limits | Tape measure, calipers |

| Eccentricity Verification | Confirm offset dimensions per design | Height gauge, dial indicator |

Stage 3: Pressure Testing (Per API 598)

Test Sequence:

- Shell Test: 1.5 × PN rating, water, ≥15 min duration

- Seat Test (Low Pressure): Air/N2 at 0.6 MPa, soap solution detection

- Seat Test (High Pressure): 1.1 × PN rating, water, ≥15 min duration

- Special Tests (if specified):

- Fire-safe simulation

- Cryogenic testing

- Fugitive emission testing

Stage 4: Functional Testing

- Full 90° operation verification

- Torque measurement at opening/closing

- Position indicator accuracy check

- Limit switch function (if automated)

5.2 Critical Inspection Focus for Eccentric Valves

- Offset Dimension Verification: Use precision instruments to confirm first, second, and (for D343X) third offset values

- Seat Installation Quality: Ensure proper compression, no gaps in laminated structures

- Bearing Clearance Check: Verify radial/axial play within specifications

- Fire-Safe Features: Confirm secondary metal seat contact surfaces

5.3 Export Preparation Checklist

Cleaning & Preservation:

- Complete internal drying after hydrotest

- Application of VCI (Vapor Corrosion Inhibitor) coatings

- Desiccant placement (calculate based on volume)

- Rust preventive on machined surfaces

Protective Packaging:

- Flange Protection: Minimum 3mm thick plastic/metal covers bolted (not taped) in place

- Stem/Gear Protection: Shrink wrapping with silica gel packets

- Internal Blocking: Wooden blocks to prevent movement during transit

- External Crating: ISPM-15 compliant wooden crates with proper reinforcement

Marking & Identification:

CRATE MARKING REQUIREMENTS:

- Consignee/Consignor information

- Package number and gross/net weight

- Handling symbols (fragile, this side up, keep dry)

- Center of gravity indication for heavy items

VALVE BODY MARKING (per MSS SP-25):

- Manufacturer's name/trademark

- Pressure class designation

- Material designation

- Directional flow arrow (if applicable)

- Heat number for pressure parts

- Fire-safe designation (if applicable)

Documentation Package:

- Commercial invoice (3 copies)

- Packing list (detailed, per crate)

- Certificate of origin

- Bill of lading/air waybill

- Insurance certificate

- Technical documentation in waterproof pouch:

- Data book with all test records

- Material certificates

- Installation, operation, maintenance manual

- Certificates of conformity

Special Precautions:

- Valve Position: Secure disc in slightly open position (5-10°) to prevent seat compression during transport

- Environmental Compliance: Verify adherence to RoHS, REACH, TSCA as per destination country

Third-Party Inspection: For critical applications, engage independent inspectors (DNV, BV, SGS) for:

- Witness of final testing

- Review of documentation

- Release certification

Common Export Defects to Avoid:

- Inadequate preservation leading to corrosion

- Improper blocking causing internal damage

- Missing or incorrect documentation

- Non-compliant wood packaging (lack of ISPM-15 marking)

- Insufficient protection of machined surfaces

5.4 Final Release Criteria

Before shipment authorization, verify:

All inspection/test reports are complete and signed

Non-conformities have been properly addressed and closed

Packaging meets all contractual and international shipping requirements

Documentation package is complete and accurate

Special customer requirements have been fulfilled

Shipping marks are clearly visible on all sides of crates

Resilient Seat Double Three Eccentric Flanged Butterfly Valve Main dimensions(mm)

Note:1. Other specifications and flange standards are available upon request.

- Design and specifications are subject to change without prior notice.

.png)

.png)