Underground Square Head Gate Valve FDZ45X

Underground Square Head Gate Valve FDZ45X Purpose

This valve is mounted on various pipelines and used as a bi-way closed circuit equipment for tap water, sewage treatment industries etc.

Underground Square Head Gate Valve FDZ45X Definition and Components

What is an FDZ45X/Z41X Valve?

This is an Underground (Buried) Service Gate Valve with a Square Operating Head. It is designed to be installed below ground level in a valve box or vault and operated with a special T-key wrench. The "FD" prefix typically indicates "buried" or "underground" service in Chinese valve codes. The core valve is a Non-Rising Stem (Z45X) or Rising Stem (Z41X) Resilient Seated Gate Valve, but modified for subsurface operation.

Water Supply Valve Main Parts:

- Valve Body: Heavy-duty ductile iron body with flanged or mechanical joint (MJ) ends, designed for direct burial.

- Buried Service Bonnet: Extended, sealed bonnet assembly that isolates the operating mechanism from soil and groundwater.

- Square Operating Head: A square nut or head (e.g., 2" square) attached to the valve stem, accessible from the surface.

- Stem Extension Rod(s): A series of threaded rods that connect the square head to the actual valve stem, adjustable to match burial depth.

- Valve Stem: Non-rising (for Z45X) or rising (for Z41X) stem connected to the gate.

- Resilient Gate: Rubber-encapsulated gate for bubble-tight shut-off.

- Protective Coatings: Thick corrosion protection like fusion-bonded epoxy (FBE) per AWWA C550 on both internal and external surfaces.

Role, Characteristics, and Application Scenarios of Underground Square Head Gate Valve FDZ45X in Pipelines

Pipeline Functions:

- Subsurface Isolation: Provides primary shut-off capability on buried water mains, allowing flow control from the surface without excavation.

- System Segmentation: Used to isolate sections of a distribution network for maintenance, repairs, or new connections.

- Pressure Zone Boundaries: Installed between different pressure zones in a municipal water system.

Gate Valve for Water Operational Features:

- Key-Operated: Requires a long T-handle wrench ("valve key") to turn the square head. Provides security and prevents unauthorized operation.

- Adjustable Height: Stem extension rods can be added or adjusted to bring the operating head to the correct grade level within the valve box.

- Corrosion Protected: Heavy-duty coatings and sealed design withstand direct contact with soil and groundwater.

- No Visual Indicator: Unlike an above-ground rising stem valve, the position (open/closed) cannot be seen and must be determined by counting turns or using a position indicator accessory.

Application Scenarios:

- Used almost exclusively in buried municipal water distribution and transmission networks.

- Street Main Valves: Installed every 500-800 feet on water mains under streets, accessible via a valve box cast into the pavement.

- Service Branch Connections: Valves isolating individual service lines to buildings or fire hydrants.

- Subdivision Entrances: Master valves at the entrance of a housing development.

Scenario Diagram (Text Description):

A water transmission main runs underground along a city street. At intervals, an FDZ45X valve is installed on the main. It sits in a bed of gravel, protected by its epoxy coating. A 2" square operating head is positioned exactly at the target grade level. Above it, a cast iron valve box is set into the asphalt, with a heavy lid marked "WATER." To operate the valve, a city worker removes the lid, inserts a long T-handle key down the box, engages the square head, and turns it to open or close the valve, controlling flow to downstream neighborhoods without ever digging up the pipe.

Underground Square Head Gate Valve FDZ45X Standards: Materials, Design, and Connections

Material Standards:

- Body & Bonnet: Ductile Iron ASTM A536 (65-45-12).

- Coatings: Fusion-Bonded Epoxy (FBE) per AWWA C550. Internal lining often specified

- Stem & Square Head: Stainless Steel (Type 316 per ASTM A276) or coated carbon steel.

- Bolts/Nuts: Hot-dip galvanized steel per ASTM A153.

- Seat/Gate: EPDM rubber, NSF/ANSI 61 certified.

Design Standards:

- AWWA C509: Standard for Resilient-Seated Gate Valves for Water Supply Service. The fundamental design standard.

- AWWA C550: Standard for Protective Interior and Exterior Coatings for Valves and Hydrants.

Connection Standards:

- Flanged: AWWA C115 (Ductile Iron) or ASME B16.1 Class 125.

- Mechanical Joint (MJ): AWWA C111. This is the most common connection for buried ductile iron pipe systems.

- Restrained Joints: Often required to resist thrust forces; must be specified.

How to Select Underground Square Head Gate Valve FDZ45X

Key Steps:

- Specify Precisely for Burial: Clearly state "For Direct Buried Service" and require compliance with AWWA C509 and C550.

Define Critical Details:

- Connection Type: MJ or Flanged? If MJ, specify class (e.g., MJ for Class 50 pipe).

- Square Head Size: Standard is 2" square. Confirm.

- Buried Depth/Extension: Specify the required operating head elevation or the typical burial depth to ensure correct extension rod length is quoted.

- Coating: Explicitly require FBE coating per AWWA C550, minimum thickness (e.g., 16 mils).

- Choose a Specialized fire protection system supplier: Select manufacturers with proven experience in AWWA underground valves, not just general industrial valve makers.

- Review Accessories: Determine if the quote includes the valve box, setting blocks, and any special tools. These are often separate.

Pre-Shipment Inspection for Export Underground Square Head Gate Valve FDZ45X and Key Considerations

Inspection Checklist:

- Coating Inspection: Check FBE coating for thickness, adhesion, and holidays (pinholes). This is the primary corrosion defense.

- Square Head Operation: Use a T-key to ensure the mechanism turns smoothly through full cycles.

- Dimensional Check: Verify flange/MJ dimensions and face-to-face length.

- Pressure Testing: Witness shell and seat tests per AWWA C509 (typically 300 psi shell test, 150 psi seat test with zero leakage).

- Material Certs: Verify ASTM and AWWA material certifications are provided.

Export Precautions:

- Protect the Coating: The FBE coating is delicate before curing and can be scratched. Protect during handling and crate the valve carefully with soft blocking.

- Protect Machined Areas: Coat the square head and stem threads with heavy grease or a preservative. Cover MJ bell ends or flange faces with durable, bolted plastic covers.

- Separate Packaging: Pack long stem extension rods separately to prevent damage inside the crate.

- Clear Marking: Mark crates prominently as "UNDERGROUND VALVE" and "PROTECT COATING." Include installation instructions and coating repair kits in the documentation pouch.

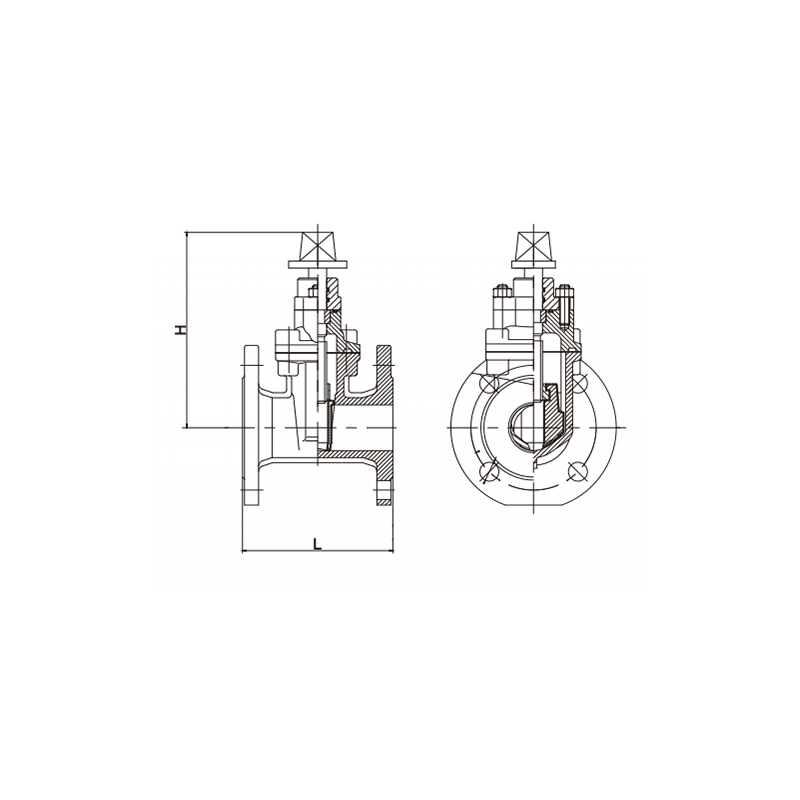

Underground Square Head Gate Valve FDZ45X Main dimensions(mm) 1.0tPa/1.8MPa

| ON | 50 | 85 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 |

| H | 288 | 290 | 310 | 365 | 405 | 467 | 530 | 625 | 705 | 1085 | 1205 |

| L(BS5163) | 178 | 190 | 203 | 229 | 254 | 267 | 292 | 330 | 356 | 381 | 406 |

| L(DINF4) | 150 | 170 | 180 | 190 | 200 | 210 | 230 | 250 | 270 | 290 | 310 |

Note:1. Other specifications and flange standards are available upon request.

2. Design and specifications are subject to change without prior notice.

.png)

.png)