Non-rising Metal Seat Gate Valve Z45T

Non-rising Metal Seat Gate Valve Z45T Definition and Components

What is a Z45T Valve?

The Z45T is a Non-rising Stem, Flanged, Metal-Seated Gate Valve. The "T" in the code indicates a copper alloy (bronze) seat. It is a bidirectional shut-off valve where the stem does not rise when operated, and sealing is achieved through metal-to-metal contact between the gate and the seat rings.

Water Supply Valve Main Parts:

- Body & Bonnet: Typically cast iron or carbon steel, forming the pressure envelope.

- Gate: A solid, wedge-shaped slab of metal (iron, steel, bronze). It is not coated in rubber.

- Seat Rings: Precision-machined rings, usually made of bronze (for the "T" designation) or stainless steel, screwed or welded into the body.

- Non-rising Stem: A threaded stem that rotates to move the gate up/down internally. The handwheel does not rise.

- Stem Nut (Yoke Nut): The internal nut that engages the stem threads, converting rotary motion to linear gate movement.

- Packing System: Seals around the stem to prevent leakage to the environment

Role, Characteristics, and Application Scenarios of Metal Seat Gate Valve in Pipelines

Pipeline Functions:

- Isolation in Harsh Service: Provides shut-off in applications where heat, abrasion, or corrosion would destroy a rubber seat.

- Flow Control: Can be used for throttling, though prolonged use in a partially open position can erode the seats.

Operational Features:

- Metal-to-Metal Seal: Robust and suitable for high temperatures (steam, hot oils) and abrasive media. However, it is not "bubble-tight" like a resilient seat; some minor leakage is standard (e.g., ANSI Class IV).

- High Operating Torque: Requires more force to operate, especially to break the seal after being closed under pressure, due to friction and potential galling.

- Space-Saving: Non-rising stem design requires less vertical clearance.

- Wear & Maintenance: Seats are subject to wear and galling. They can often be lapped or re-machined in place for maintenance.

Gate Valve for Water Application Scenarios:

- Used in services where temperature, abrasion, or chemical compatibility preclude the use of elastomers.

- Steam Lines: Low to medium-pressure saturated steam systems.

- Hot Oil/Heat Transfer Fluid Systems: In industrial heating processes.

- Abrasive Slurries: In mining or wastewater where particles would cut a rubber seat (with suitable material selection).

- Fuel Oil Lines: In boiler feed or industrial heating systems.

Scenario Diagram (Text Description):

In an industrial boiler plant, a Z45T valve is installed on the saturated steam header. The constant 180°C temperature would quickly degrade an elastomer seat. The valve's bronze seats and iron wedge provide a durable, metal seal. An operator uses a wheel wrench on the non-rising stem to close the valve for maintenance on a downstream steam trap. The fire protection valve operates with high torque but reliably isolates the section. Over years of service, the seats may wear and begin to leak slightly, at which point they can be lapped to restore an acceptable seal, demonstrating the maintainable nature of the metal-seat design.

Non-rising Metal Seat Gate Valve Z45T Standards: Materials, Design, and Connections

Material Standards:

- Body/Bonnet: Cast Iron (ASTM A126), Carbon Steel (ASTM A216 WCB).

- Seat Rings: Bronze (ASTM B62), Stainless Steel (ASTM A351 CF8).

- Gate: Carbon Steel, Stainless Steel, or Bronze.

- Stem: Stainless Steel (ASTM A276 416/304) or Bronze.

Design Standards:

- API 600 / ISO 10434: Primary standards for bolted bonnet steel gate valves.

- ASME B16.34: Valves - Flanged, Threaded, and Welding End.

- MSS SP-70: For cast iron gate valves.

Connection Standards:

- Flanges: ASME B16.5 Class 150 or 300, with Raised Face (RF) typical.

- Face-to-Face: ASME B16.10 dimensions.

How to Select Non-rising Metal Seat Gate Valve Z45T

Key Steps:

- Define Service Severity: Clearly state the fluid, maximum/minimum temperature, presence of abrasives, and cycle frequency. This dictates material choice (e.g., bronze for steam, stainless for corrosion).

- Specify Leakage Class: Understand and specify the acceptable leakage rate per API 598 (e.g., Class IV is standard for metal seats).

- Select Materials for Wear: For abrasive service, specify hardened seats or gates (e.g., 13% Cr, Stellite facing).

- Consider Operation: For high torque or frequent operation, request a gear operator instead of a standard handwheel.

Pre-Shipment Inspection for Export Non-rising Metal Seat Gate Valve Z45T and Key Considerations

Inspection Checklist:

- Seat/Gate Inspection: Check the machined sealing surfaces for finish, smoothness, and absence of defects. Verify wedge-to-seat contact pattern if possible.

- Operation Test: Ensure the valve opens and closes smoothly. Measure and record the operating torque.

- Pressure Testing: Witness tests per API 598. For metal seats, the seat leakage test allows a specified droplet rate per minute (not zero). Ensure the test duration and method are correct.

- Material Verification: Check material certificates for seat rings and gate against the purchase order.

Export Precautions:

- Preserve Seating Surfaces: Apply a generous coating of neutral grease or anti-seize compound on the gate and seat faces to prevent rust and corrosion during transit. This is critical.

- Secure Internal Parts: Ensure the gate is in the mid-open position to avoid embedding the wedge into the seats under shock loads.

- Protect Flanges: Use bolted, rigid covers on flange faces.

- Documentation: Include all material certs and pressure test reports, explicitly stating the leakage class achieved.

Non-rising Metal Seat Gate Valve Z45T Materials

| Parts | Material |

| Body | Ductile iron |

| Body seat ring | Cast brass |

| Wedge | Ductile iron |

| wedge seat ring | Cast brass |

| Stem | Stainless steel |

| Bolt | Steel |

| Nut | Steel |

| Gasket | Graphite |

| Bonnet | Ductile iron |

| Packing | Graphite |

| Gland Follower | Ductile iron |

| Nut | Steel |

| Bolt | Steel |

| Stem nut | Cast brass |

| Hand wheel washer | Cast bronze |

| Hand wheel | Ductile iron |

| Hand wheel nut | Ductile iron |

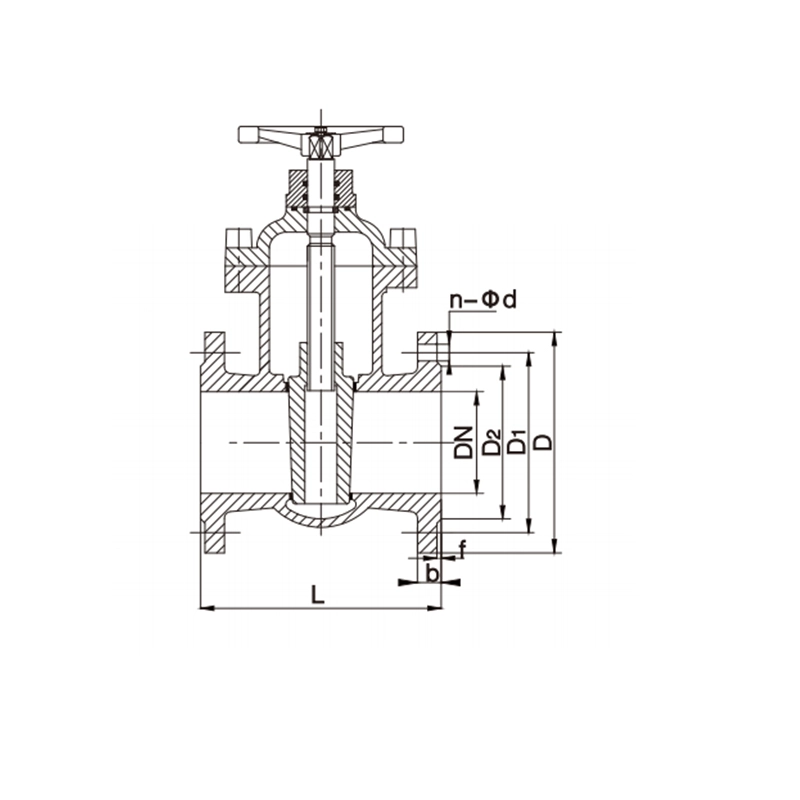

Non-rising Metal Seat Gate Valve Z45T Main dimensions(PN16/PN10)

| Size | 40 | 50 | 65 | 100 | 125 | 150 | 200 | 250 | 300 |

| L | 165 | 178 | 190 | 203 | 254 | 267 | 292 | 330 | 356 |

| D | 150 | 165 | 179 | 194 | 245 | 278 | 322 | 405/395 | 460/445 |

| D1 | 110 | 125 | 145 | 160 | 210 | 240 | 265 | 355/350 | 410/400 |

| D2 | 88 | 102 | 122 | 138 | 188 | 212 | 268 | 320 | 370 |

| b | 18 | 19 | 19 | 19 | 20 | 2 | 22 | 24.5 | 24.5 |

| f | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 4 |

| N-d | 4-19 | 4-19 | 4-19 | 8-19/4-19 | 8-19 | 8-23 | 12-23/8-23 | 12-28/12-23 | 12-28/12-23 |

Note:1. Other specifications and flange standards are available upon request.

- Design and specifications are subject to change without prior notice.

.png)

.png)