API Swing Check Valve

API Swing Check Valve Definition and Components

What is an API Swing Check Valve and its main parts?

An API Swing Check Valves is a type of check valve designed and manufactured to the standards of the American Petroleum Institute (API). It is a full-bore, metal-seated valve that allows fluid to flow in one direction only and automatically closes to prevent backflow when the flow stops or reverses. Its characteristic feature is a disc (or "clapper") that swings on a hinge pin, like a door on a hinge.

Main Parts:

- Body: The main pressure-retaining housing, with either a flanged or butt-weld end. It typically has a Y-pattern or inclined seat design to minimize pressure drop.

- Cover/Bonnet: The bolted access cover that allows for inspection and maintenance of the internal components.

- Disc (Clapper): The closure element that swings open with forward flow and swings shut against reverse flow.

- Hinge Arm/Pin: The assembly that allows the disc to pivot. It consists of a lever arm attached to the disc and a hardened pin or bearing mounted in the body.

- Seat Ring: A hardened, machined ring (often made of stainless steel or with a stellite face) that is pressed or welded into the body. The disc seals against this ring when closed.

- Counterweight or Dashpot (Optional): A counterweight can be attached to the hinge arm to control the closing speed. For critical applications, a hydraulic dashpot can be added to prevent slamming and water hammer.

Role, Characteristics, and Application Scenarios of API Swing Check Valve in Pipelines

Functions, Operational Features, Usage Scenarios, and Scenario Diagram

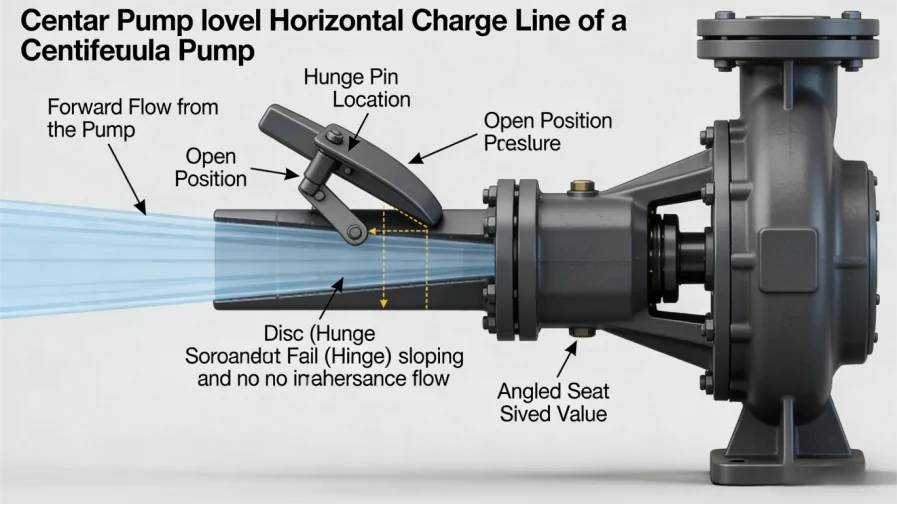

Functions: Its sole function is to prevent reverse flow (backflow) in a pipeline. It operates automatically based on fluid dynamics.

Operational Features:

- Automatic, Self-Acting: No external operator or signal is required.

- Full-Bore Design: When fully open, the disc swings completely out of the flow path, offering minimal flow resistance.

- Swing-to-Close Action: Closing relies on gravity and/or reverse flow pressure pushing the disc back onto the seat. The disc is not spring-loaded (in basic design).

- Prone to Water Hammer/Slam: In systems with rapid flow stoppage (e.g., pump trip), the disc can slam shut violently, causing pressure surges. This necessitates optional dampers.

- Usage Scenarios: Ideal for horizontal or vertical (upward flow) pipelines with relatively steady, high-volume flows.

- Pump Discharge Outlets: To prevent backflow through a stopped pump.

- Compressor and Blower Discharge Lines.

- Oil & Gas Gathering and Transmission Pipelines.

- Refinery Process Lines.

- Water Injection Lines.

API Swing Check Valve Standards: Materials, Design, and Connections

Material, Design, and Connection Standards

industrial valves Material Standards:

- Primary Material: ASTM A216 WCB (Carbon Steel) is common. For corrosive services, materials like ASTM A351 CF8M (316 SS) or duplex stainless steel are used.

- Trim (Seat & Disc): Typically hardened 13% Chrome stainless steel or Stellite-faced for wear and corrosion resistance.

- Hinge Pin/Bushings: Hardened stainless steel or material with good wear properties.

- Design Standards: The primary standard is API 6D ("Pipeline Valves") or its more specific counterpart, API 594 ("Check Valves: Flanged, Lug, Wafer, and Butt-welding Ends"). These standards govern design, dimensions, pressure-temperature ratings, testing, and face-to-face lengths.

Connection Standards:

- Flanged Ends: ASME B16.5 (Class 150, 300, 600, etc.), typically with Raised Face (RF) or Ring-Type Joint (RTJ) facings.

- Butt-Weld Ends: ASME B16.25 for end preparation.

- Face-to-Face: Dimensions per API 6D/594 or ASME B16.10.

How to Select API Swing Check Valve

How to Purchase

- Define Service Conditions: Specify size (NPS), pressure class (ASME Class), fluid (including corrosiveness, presence of solids), temperature, and required leakage class per API 598. Decide on the need for a dashpot or counterweight.

- Source from API-Licensed Manufacturers: Purchase from manufacturers holding the API Monogram License for API 6D or API 594. This is a critical mark of quality and adherence to the standard.

Request Detailed Technical Proposal: Ask for:

- Datasheet with full material specification (body, trim, internals).

- Dimensional drawings showing face-to-face, hinge orientation, and overall dimensions.

- Cv (Flow Coefficient) or pressure drop data.

- Proof of API Monogram license and any fire-safe certification (API 6FA/607) if required.

- Evaluate and Order: Compare technical compliance, certification, price, and lead time. The purchase order must explicitly reference: API 6D or API 594, size, pressure class, material specs, end connection, and any special testing (e.g., NACE MR0175 for sour service).

Pre-Shipment Inspection for Export API Swing Check Valve and Key Considerations

Pre-Export Inspection and Precautions

Inspection Protocol (API Compliance is Key):

- Documentation Review: Verify the API Monogram is stamped on the valve body. Check Material Test Reports (MTRs) for all pressure-containing and critical wear parts.

- Dimensional & Marking Check: Confirm all markings (API symbol, size, class, material, manufacturer ID). Verify face-to-face and flange dimensions.

- Visual & Functional Check: Inspect the internal cavity for cleanliness and proper machining. Manually swing the disc through its full arc to ensure it moves freely without binding and seats properly with a clean "metal-on-metal" contact.

- Witness API Pressure Testing: Testing must be per API 598 (Gate, Globe, and Check Valves). Key tests include:

- Shell Hydrostatic Test: 1.5x the rated pressure.

- Backflow Pressure Test (Seat Test): The valve is installed in a test rig in the reverse flow direction and tested at 1.1x rated pressure (or as per purchase order) to verify the disc/seat seal under backflow conditions. This is the critical test for a check valve.

- Additional Checks: For valves with dashpots, verify the dashpot is filled with the correct fluid and functions smoothly.

Precautions:

- Shipping Position: The valve must be shipped with the disc mechanically secured in the open position using a shipping strap or block. This prevents the disc from slamming inside the body during transit, which can damage the seat or hinge.

- Protect Sealing Surfaces: Apply a soft, removable coating on the seat and disc face. Use rigid flange protectors.

- Orientation: Clearly mark the flow direction arrow on the crate. The valve's design is not bidirectional.

- Complete Documentation Dossier: Ensure shipment includes: API Certified Test Reports, MTRs, Certificate of Conformity, installation manual (emphasizing proper orientation), and packing list. Place in a waterproof envelope.

- Export Packing: Use robust wooden crates. Internally brace the valve to prevent movement. Mark crates with "Flow Direction," "Secure Internally," and "Lift Here."

API Swing Check Valve Function and specification

| Type . |

Nominal pressure (MPa) |

Testing pressure | Suitable temperature(℃) |

Suitable medium | |

| TecTOBoe naBneHMe | |||||

| Strength(Water)(MPa) | Enclose(Water)(MPa) | ||||

| H44YH-16C | 1.6 | 2.4 | 1.6 | ≤425 | Water,Vapour,Oil |

| H44YH-25 | 2.5 | 3.8 | 2.5 | ||

| H44YH-40 | 4.0 | 6.15 | 4.0 | ||

| H44YH-64 | 6.4 | 9.75 | 6.4 | ||

| H44YH-100 | 10.0 | 14.4 | 10 | ||

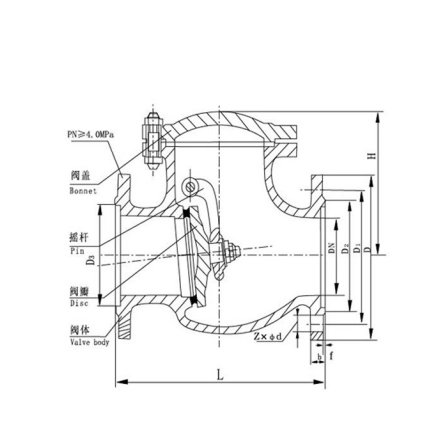

API Swing Check Valve Outline and connecting measurement

| Type | Nominal DN(mm) |

Measurement(mm) | Reference Weight(kg) |

|||||||

| L | D | Di | D₂ | D₃ | b-f | Z×φd | H | |||

| H44YH -16C |

40 | 200 | 145 | 110 | 85 | 16-3 | 4×φ18 | 126 | 10 | |

| 50 | 230 | 160 | 125 | 100 | 16-3 | 4×φ18 | 132 | 13 | ||

| 65 | 290 | 180 | 145 | 120 | 18-3 | 4×φ18 | 151 | 19.2 | ||

| 80 | 310 | 195 | 160 | 129 | 20-3 | 8×φ18 | 164 | 25.8 | ||

| 100 | 350 | 215 | 180 | 155 | 20-3 | 8×φ18 | 185 | 33.9 | ||

| 125 | 400 | 245 | 210 | 185 | 22-3 | 8×φ18 | 202 | 47.8 | ||

| 150 | 480 | 280 | 240 | 210 | 24-3 | 8×φ23 | 223 | 71.3 | ||

| 200 | 495 | 340 | 295 | 266 | 24-2 | 12×φ22 | 350 | 137 | ||

| H44YH-25 | 40 | 200 | 150 | 110 | 84 | 18-2 | 4×φ18 | 150 | 10 | |

| 50 | 230 | 165 | 125 | 99 | 20-2 | 4×φ18 | 160 | 13 | ||

| 65 | 290 | 185 | 145 | 118 | 22-2 | 8×φ18 | 175 | 20.7 | ||

| 80 | 310 | 200 | 160 | 132 | 24-2 | 8×φ18 | 185 | 26.6 | ||

| 100 | 350 | 235 | 190 | 156 | 24-2 | 8×φ22 | 220 | 40.35 | ||

| 125 | 400 | 270 | 220 | 184 | 26-2 | 8×φ26 | 248 | 64.25 | ||

| 150 | 480 | 300 | 250 | 211 | 28-2 | 8×φ26 | 270 | 97 | ||

| 200 | 533 | 360 | 310 | 274 | 30-2 | 12×φ26 | 350 | 137 | ||

| H44YH-40 | 50 | 230 | 160 | 125 | 100 | 88 | 20-3 | 4×φ18 | 175 | 22 |

| 65 | 290 | 180 | 145 | 120 | 110 | 22-3 | 8×φ18 | 190 | 30 | |

| 80 | 310 | 195 | 160 | 135 | 121 | 22-3 | 8×φ18 | 190 | 34 | |

| 100 | 350 | 230 | 190 | 160 | 150 | 24-3 | 8×φ23 | 215 | 52 | |

| 125 | 400 | 270 | 220 | 188 | 176 | 28-3 | 8×φ25 | 260 | 73 | |

| 150 | 480 | 300 | 250 | 218 | 204 | 30-3 | 8×φ25 | 270 | 103 | |

| 200 | 550 | 375 | 320 | 282 | 260 | 38-3 | 12×φ30 | 340 | 212 | |

| 250 | 650 | 445 | 385 | 345 | 313 | 42-3 | 12×φ34 | 400 | 297 | |

| 300 | 750 | 510 | 450 | 408 | 364 | 46-4 | 16×φ34 | 425 | 362 | |

| 350 | 850 | 570 | 510 | 465 | 422 | 52-4 | 16×φ34 | 460 | 450 | |

| 400 | 950 | 655 | 585 | 535 | 474 | 58-4 | 16×φ41 | 490 | 585 | |

API Swing Check Valve Outline and connecting measurement

| Type | Nominal DN(mm) |

Measurement(mm) | Reference Weight (kg) |

|||||||

| L | D | Di | D₂ | D₃ | b-f | Z×φd | H | |||

| H44YH -64 |

50 | 300 | 175 | 135 | 105 | 88 | 26-3 | 4×φ23 | 190 | 30 |

| 65 | 340 | 200 | 160 | 130 | 110 | 28-3 | 8×φ23 | 205 | 41 | |

| 80 | 380 | 210 | 170 | 140 | 121 | 30-3 | 8×φ23 | 205 | 48 | |

| 100 | 430 | 250 | 200 | 168 | 150 | 32-3 | 8×φ25 | 235 | 72 | |

| 125 | 500 | 295 | 240 | 202 | 176 | 36-3 | 8×φ30 | 265 | 108 | |

| 150 | 550 | 340 | 280 | 240 | 204 | 38-3 | 8×φ34 | 295 | 155 | |

| 200 | 650 | 405 | 345 | 300 | 260 | 44-3 | 12×φ34 | 355 | 217 | |

| 250 | 775 | 470 | 400 | 352 | 313 | 48-3 | 12×φ41 | 405 | 341 | |

| 300 | 900 | 530 | 460 | 412 | 364 | 54-4 | 16×φ41 | 465 | 472 | |

| 350 | 1025 | 595 | 525 | 475 | 422 | 60-4 | 16×φ41 | 505 | 627 | |

| 400 | 1150 | 670 | 585 | 525 | 474 | 66-4 | 16×φ48 | 570 | 882 | |

| H44YH -100 |

50 | 300 | 195 | 145 | 112 | 88 | 28-3 | 4×φ25 | 192 | 41 |

| 65 | 340 | 220 | 170 | 138 | 110 | 32-3 | 8×φ25 | 207 | 48 | |

| 80 | 380 | 230 | 180 | 148 | 121 | 34-3 | 8×φ25 | 235 | 72 | |

| 100 | 430 | 265 | 210 | 172 | 150 | 38-3 | 8×φ30 | 265 | 108 | |

| 125 | 500 | 310 | 250 | 210 | 176 | 42-3 | 8×φ34 | 313 | 130 | |

| 150 | 550 | 350 | 290 | 250 | 204 | 46-3 | 12×φ34 | 360 | 217 | |

| 200 | 650 | 430 | 360 | 312 | 260 | 54-3 | 12×φ41 | 420 | 341 | |

| 250 | 775 | 500 | 430 | 382 | 313 | 60-3 | 12×φ41 | 480 | 472 | |

| 300 | 900 | 585 | 500 | 442 | 364 | 70-4 | 16×φ48 | 540 | 598 | |

We also supply fire valve and water valves.

.png)

.png)