Bellow Sealed Globe Valve

Bellow Sealed Globe Valve Definition and Components

What is a DWJ41H Valve?

The DWJ41H is a Bellow Sealed Globe Valves with a flanged connection, a straight-through flow design (indicated by '1'), and a hardened stainless steel seat ('H'). Its defining feature is a hermetically sealed metallic bellows assembly that replaces or supplements traditional stem packing, creating a primary seal against the atmosphere. This design is specifically for containing hazardous, toxic, expensive, or ultra-pure media.

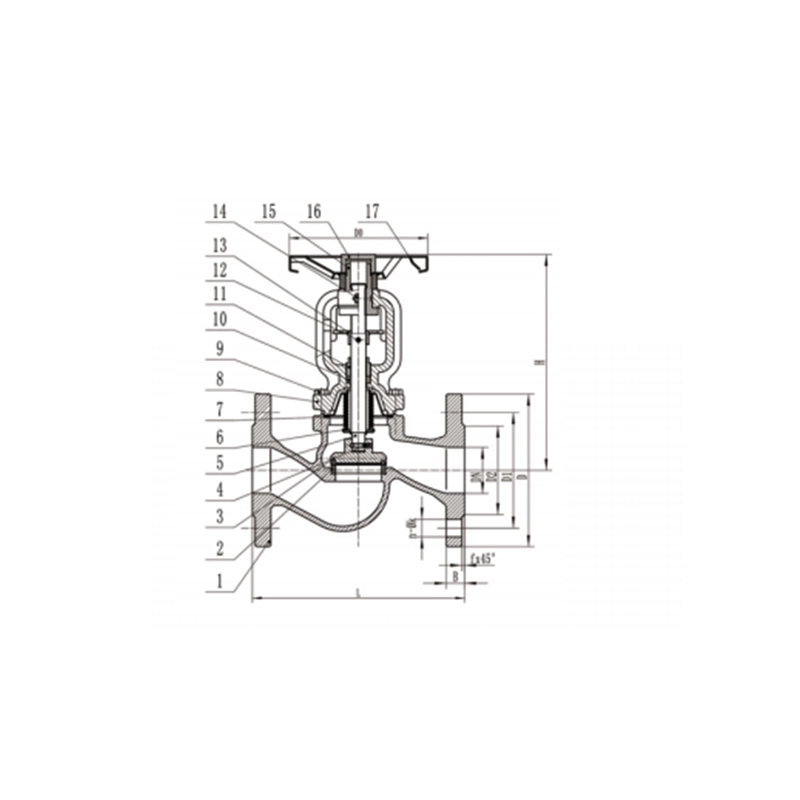

Main Parts:

- Valve Body: The main pressure-retaining component with a flanged, Z-shaped (globe) flow path. Typically carbon steel (WCB) or stainless steel.

- Bonnet: Connects to the body, housing the stem and bellows assembly.

- Metallic Bellows Assembly: The core component. A series of welded thin-walled metal diaphragms (usually 316L stainless steel) that compress and extend. It forms a hermetic, leak-proof seal around the stem.

- Stem: Connected to the handwheel and the plug, transmitting motion through the bellows.

- Plug (or Disc): The closure element that mates with the seat to stop flow. Often hardened or stellited for durability.

- Seat Ring: The stationary sealing surface, typically hardened stainless steel.

- Secondary Packing: A backup stem packing gland located above the bellows, providing safety if the bellows fails.

Role, Characteristics, and Application Scenarios of Bellow Sealed Globe Valve in Pipelines

Globe Valve for Water Pipeline Functions:

- Zero Fugitive Emission Shut-off/Regulation: Its primary function is to completely eliminate external leakage of the process fluid, especially critical for gases or volatile liquids.

- Precise Flow Control: The globe valve design allows for fine flow throttling and control.

Operational Features:

- Leak-proof to Atmosphere: The metal bellows provide a hermetic seal, making the valve ideal for emission control.

- High Reliability for Critical Service: Designed for handling dangerous, toxic, or expensive fluids where leakage is unacceptable.

- Higher Cost and Maintenance: Significantly more expensive than packed valves. Bellows have a finite cycle life and can fail from fatigue or corrosion.

- Reduced Maintenance: Eliminates the need for periodic packing adjustment or replacement under normal conditions.

Water Valves Application Scenarios:

- Used wherever stem leakage is a safety, environmental, or product loss concern.

- Toxic & Hazardous Chemicals: In pharma and fine chemical plants handling lethal substances.

- Volatile Organic Compounds (VOCs): For compliance with environmental emission regulations (EPA, TA-Luft).

- Ultra-High Purity Systems: In semiconductor or food & beverage industries to prevent contamination.

- Vacuum and Cryogenic Service: Where traditional packing is ineffective.

Scenario Diagram (Text Description):

In a pharmaceutical API (Active Pharmaceutical Ingredient) synthesis plant, a highly toxic and volatile solvent is transported through a process line. A DWJ41H valve is installed as the main isolation valve on this line. The metallic bellows seal ensures that zero solvent vapor leaks from the valve stem into the plant atmosphere, protecting worker safety and preventing environmental release. During batch operation, the valve is used to precisely throttle the flow of this expensive solvent into the reactor. The valve's secondary packing acts as a safety backup, containing any leak should the primary bellows seal ever fail.

Bellow Sealed Globe Valve Standards: Materials, Design, and Connections

Material Standards:

- Body/Bonnet: ASTM A216 WCB (CS), ASTM A351 CF8/CF8M (SS).

- Bellows: ASTM A312 / A269 316L Stainless Steel (low carbon for welding).

- Seat/Plug: Hardened 316SS, Stellite (Co-Cr alloy) faced.

- Gaskets: Spiral-wound (SS+Graphite) for body-bonnet joint.

Design Standards:

- API 602: For compact steel gate valves (often referenced for design rules).

- ASME B16.34: Valves - Flanged, Threaded, and Welding End.

- ISO 15848-1: Fugitive Emissions - Testing and Classification. Valves are often Type-Tested to this standard.

- Shell MESC SPE 77/312: A common corporate standard for valve procurement.

Connection Standards:

Flanges: ASME B16.5 Class 150 or 300, Raised Face (RF).

How to Select Bellow Sealed Globe Valve

Key Steps:

Define the Critical Need: Justify the high cost by specifying the exact reason (e.g., toxic media, VOC compliance, high purity). The service fluid is the most critical specification.

Specify Bellows Details:

- Material: Must be compatible with the process fluid (e.g., 316L, Hastelloy C276).

- Cycle Life: Require a minimum guaranteed number of open/close cycles (e.g., 10,000 cycles).

- Pressure Rating: The bellows must be rated for both the system pressure and any potential pressure from the backup packing gland.

- Request Emission Certification: For regulated applications, require certified test reports per ISO 15848-1 (Class AH/BH) or TA-Luft.

- Plan for Failure: Ensure the design includes a secondary containment seal (backup packing) and specify how bellows failure is indicated (e.g., a tell-tale port on the bonnet).

Pre-Shipment Inspection for Export Bellow Sealed Globe Valve and Key Considerations

Inspection Checklist:

- Bellows Integrity Test (MOST CRITICAL): A helium mass spectrometer leak test under vacuum is the gold standard. Every bellows assembly must be tested to ensure zero leakage. This is non-negotiable.

- Pressure Testing: Standard shell and seat tests per API 598.

- Stroking Test: Operate the valve through its full travel multiple times to check for smooth bellows movement and binding.

- Dimensional Check: Verify flange dimensions and face-to-face length.

Export Precautions:

- Protect the Bellows: The bellows assembly is extremely delicate. The valve must be shipped with the stem in the FULLY OPEN position to keep the bellows in a neutral, unstressed state. Secure the handwheel to prevent movement.

- Rigid Packaging: Use a custom wooden crate with internal blocking that absolutely prevents any impact or compression on the bonnet/bellows area. Mark the crate with clear warnings.

- Documentation: Ensure the helium leak test report, material certificates for the bellows, and cycle life warranty are included in the shipment documents.

Bellow Sealed Globe Valve Materials

| No. | Parts | Materials | German Standards | |

| 1 | Body | Ductile iron | DIN1693 GGG40 | |

| 2 | Body Seat Ring | Stainless Steel | DIN17440XSCrNi189 | |

| 3 | Disc Seat Ring(DN65-200) | Stainless Steel | DIN17440XSCrNI189 | |

| 4 | DN15-50 | DIN17440X20Cr13 | DIN17440X20Cr13 | |

| DN65-200 | DIN1693 GGG40 | DIN1693 GGG40 | ||

| 5 | Screw | Steel | DIN17100 RSt37-2 | |

| 6 | Steel Ball | Steel | DIN17230 100Cr6 | |

| 7 | Gasket | Graphite | ||

| 8 | Bolt | Steel | DIN17100 RSt37-2 | |

| 9 | Packing | Graphite | ||

| 10 | Stem | Stainless Steel | DIN17440X20Cr13 | |

| 11 | Glander Follower | Ductile iron | DIN1693 GGG40 | |

| 12 | Nut | Steel | DIN17100 RSt37-2 | |

| 13 | T-Bolt | Steel | DIN17100 RSt37-3 | |

| 14 | Bonnet | Ductile iron | DIN1693 GGG40 | |

| 15 | Handwheel | Cast iron | DIN1691 GG25 | |

| 17 | Washer | Steel | DIN17100 RSt37-2 | |

Bellow Sealed Globe Valve Main dimensions(PN16/PN10)

| Size | L | D | D1 | D2 | B | f | n-Фk | D0 | H |

| DN15 | 130 | 95 | 65 | 46 | 14 | 2 | 4-Ф14 | 100 | 160 |

| DN20 | 150 | 105 | 75 | 56 | 16 | 2 | 4-Ф14 | 100 | o |

| DN25 | 160 | 115 | 85 | 65 | 16 | 3 | 4-Ф14 | 120 | 166 |

| DN32 | 180 | 140 | 100 | 76 | 18 | 3 | 4-Ф19 | 120 | 195 |

| DN40 | 200 | 150 | 110 | 84 | 19 | 3 | 4-Ф19 | 140 | 199 |

| DN50 | 230 | 165 | 125 | 99 | 20 | 3 | 4-Ф19 | 140 | 235 |

| DN65 | 290 | 185 | 145 | 118 | 20 | 3 | 4-Ф19 | 200 | 261 |

| DN80 | 310 | 200 | 160 | 132 | 20 | 3 | 8-Ф19 | 200 | 300 |

| DN100 | 350 | 220 | 180 | 156 | 21 | 3 | 8-Ф19 | 240 | 357 |

| DN125 | 400 | 250 | 210 | 184 | 21 | 3 | 8-Ф19 | 280 | 396 |

| DN150 | 480 | 285 | 240 | 211 | 23 | 3 | 8-Ф23 | 315 | 465 |

| DN200 | 600 | 340 | 295 | 266 | 23 | 3 | Ф23/8-Ф23 | 360 | 488 |

Note:1. Other specifications and flange standards are available upon request.

- Design and specifications are subject to change without prior notice.

.png)

.png)