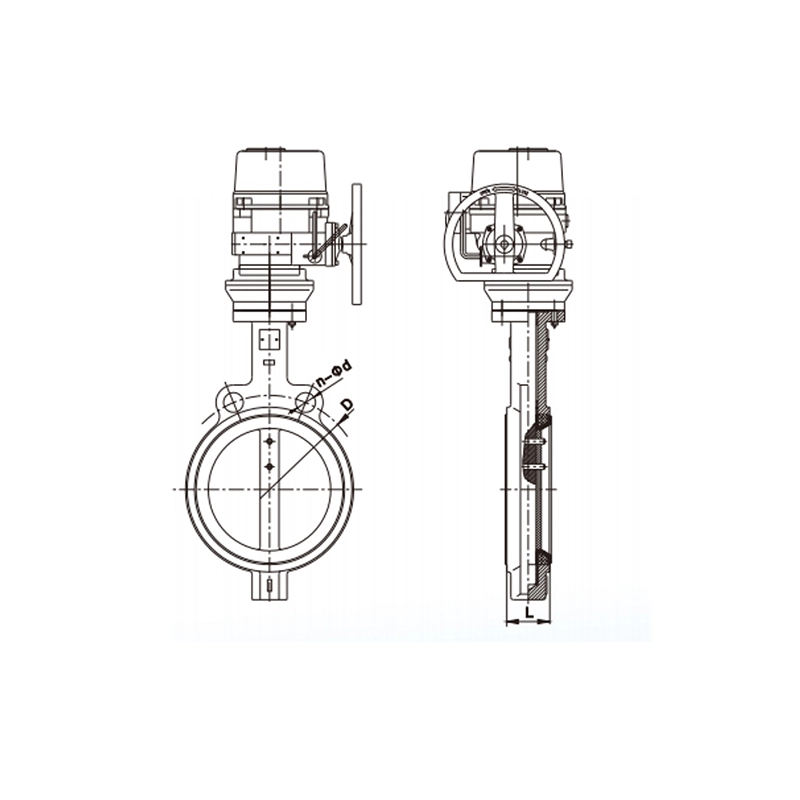

Electric Wafer Butterfly Valve D971X

Electric Wafer Butterfly Valve D971X Purpose

This valve is used for cutoff or flow adjustment in building, chemical, environmental protection, industrial and mining etc

Electric Wafer Butterfly Valve D971X Definition and Components

An Electric Wafer Butterfly Valve Model D971X is an automated quarter-turn isolation and control valve. An electric actuator replaces the manual lever or gear operator, enabling remote and automatic operation from a control system. The "D971X" designation typically indicates: D = Butterfly Valve, 9 = Electric Actuator, 71 = Wafer Body Style, X = EPDM Seat. It's a core component for modern, automated fluid handling systems.

Fire protection water supply Main Parts:

- Wafer Valve Body: Ductile iron or stainless steel body designed to be clamped between pipeline flanges.

- Disc & Stem Assembly: The flow control element (disc) connected to a shaft (stem).

- Resilient Seat (EPDM): Provides bubble-tight shut-off.

- Electric Actuator: The motorized unit that drives the valve. Contains:

- Electric Motor: The power source (AC or DC voltage).

- Gear Train: Reduces motor speed and increases output torque.

- Limit Switches: Internal switches that cut power at fully open and fully closed positions.

- Position Feedback Potentiometer or Encoder: Sends a signal (e.g., 4-20mA, 0-10V DC) indicating the valve's open percentage.

- Manual Override: A handwheel or lever for manual operation in case of power failure.

Role, Characteristics, and Application Scenarios of Electric Wafer Butterfly Valve D971X in Pipelines

Butterfly Valve for Water Functions in Pipelines:

- Remote On/Off Control: Open or close the valve from a centralized control room or remote location.

- Automated Process Control: Integrate into a PLC/SCADA system to automatically start/stop flow based on timers, levels, pressures, or other process signals.

- Modulating/Throttling Control: (With a modulating-type actuator) Precisely adjust the disc position to regulate flow rate, pressure, or level in real-time.

- Emergency Shut-down (ESD): Act as a reliably activated isolation point in safety interlock chains.

Operational Features:

- Power Options: Common voltages: 24V DC, 110V AC, 220V AC, 380V AC.

Control Modes:

- On/Off (2-point control): Simple open/close command.

- Modulating (3-point control): Requires open/stop/close signals.

- Smart Actuators: Accept analog control signals (e.g., 4-20mA) and provide analog position feedback.

- Fail-Safe Mode: Optional spring-return mechanisms to drive the valve to a predefined safe position (Open or Closed) upon power loss.

- High Cycle Life: Designed for frequent operation.

Common Usage Scenarios:

- Building Automation Systems (BAS): Control cooling/heating water flow in HVAC systems.

- Water & Wastewater Treatment: Automate filter backwash sequences, chemical dosing, and pump control.

- Industrial Process Lines: For batch processing, remote tank filling/isolation, and reactor feed control.

- Irrigation Systems: Scheduled, automated zone control.

Electric Wafer Butterfly Valve D971X Standards: Materials, Design, and Connections

Material Standards (Valve Body):

- Body: Ductile Iron (ASTM A536) with epoxy coating. Stainless Steel (AISI 316/304) for corrosive service.

- Disc/Stem: Stainless Steel (AISI 304, 316).

- Seat: EPDM per ASTM D2000.

Design & Performance Standards (Valve):

- API 609: Design standard for the butterfly valve body.

- ISO 5211: Standard mounting interface between actuator and valve.

- IEC 60534: Industrial-process control valves (for modulating performance).

- Pressure Rating: Typically PN10/PN16 (Class 150).

Design & Performance Standards (Electric Actuator):

- IEC 60034 / NEMA MG 1: Standards for electric motors.

- IP (Ingress Protection) Rating: e.g., IP67 (dust-tight and protected against temporary immersion). Critical for outdoor or washdown areas.

- Explosion-Proof Certification: For hazardous areas: ATEX (EU), IECEx (International), or UL/CSA (North America) with specific zone/division ratings.

- Duty Cycle: Standard is S2 - 15 minutes or S4 for frequent operation.

Connection Standards:

- Valve Body: Standard wafer dimensions per ISO 5752 for fitting between ANSI B16.5 flanges.

- Actuator Mounting: ISO 5211 mounting pad ensures interchangeability.

- Electrical Conduit: Actuator typically has a standard ½" NPT or M20 threaded entry for cable glands.

How to Select Such Valves

Purchasing Guide:

- Define Valve Body Specifications:

- Size, Pressure, Media: As with manual valves: pipe size, pressure class (PN16), and fluid compatibility (confirm EPDM is suitable).

- Body Material: Epoxy-coated ductile iron is standard.

Specify Electric Actuator Requirements (CRITICAL):

- Voltage & Phase: e.g., 220V AC, 1-Phase, 50Hz.

- Control Mode: On/Off or Modulating?

- Modulating Signal: If required, specify input signal (e.g., 4-20mA) and required position feedback signal.

- Fail-Safe Action: Required? (e.g., Spring-Return to Close on power loss).

- IP Rating: Minimum IP65 for general industry, IP67/IP68 for harsh/wet environments.

- Hazardous Area Certification: If needed, specify the exact certification and zone (e.g., ATEX II 2G Ex d IIC T6).

- Accessories: Request Heater & Thermostat for cold climates to prevent condensation, Solenoid Valve for emergency trip, Position Transmitter.

Integration & Quality Requirements:

- Torque & Speed: Ensure the actuator's output torque exceeds the valve's required torque. Specify opening/closing speed if critical.

- Documentation: Require wiring diagrams, installation manuals, and actuator tuning software (for smart actuators).

- Testing: Request a function test report from the factory, confirming limit switch setting, feedback calibration, and fail-safe operation.

Pre-Shipment Inspection for Export Electric Wafer Butterfly Valve D971X and Key Considerations

Visual & Mechanical Inspection:

- Check valve body and actuator housing for physical damage.

- Ensure the manual override operates smoothly when disengaging the motor.

- Verify all nameplate data on both valve and actuator match the purchase order (voltage, IP rating, torque, etc.).

Electrical & Functional Testing (Key Differentiator from Manual Valves):

- Power-Up Test: Apply the correct voltage. The actuator should not run unless a control signal is given (prevents accidental movement).

- Control Signal Test: Simulate "OPEN" and "CLOSE" commands. Verify the valve moves to the correct end positions and the limit switches cut power.

- Feedback Verification: For modulating actuators, apply a 4-20mA signal and measure the corresponding valve position. Check feedback output.

- Fail-Safe Test (if spring-return): With valve mid-stroke, cut power. It should automatically drive to the fail-safe position.

- Seal Integrity: Review the valve body pressure test certificate (API 598) separately.

Fire Protection System Supplier Packaging Inspection:

- The actuator must be locked in a mid-stroke position for transport to prevent gear damage from vibration.

- The electrical terminal box must be sealed with a gasket and all conduit entries plugged.

- Valve body protection as per standard (covers on faces).

Electric Wafer Butterfly Valve D971X Main dimensions(mm)

| DN | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

| L | 33 | 43 | 46 | 46 | 52 | 56 | 56 | 60 | 68 | 78 | 78 | 90 | 114 | 127 | 154 |

| D | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 355 | 410 | 470 | 525 | 585 | 650 | 770 |

| n- Ф d | 4-19 | 4-19 | 4-19 | 8-19 | 8-19 | 8-19 | 8-23 | 12-23 | 12-28 | 12-28 | 16-28 | 16-31 | 20-31 | 20-34 | 20-37 |

| Model of electric actuator | QT10 | QT10 | QT10 | QT10 | QT20 | QT20 | QT30 | QT40 | QT60 | QT80 | QT90 | QT100 | QT5X | QT5X | QT5X |

Note:1. Other specifications and flange standards are available upon request.

- Design and specifications are subject to change without prior notice.

.png)

.png)