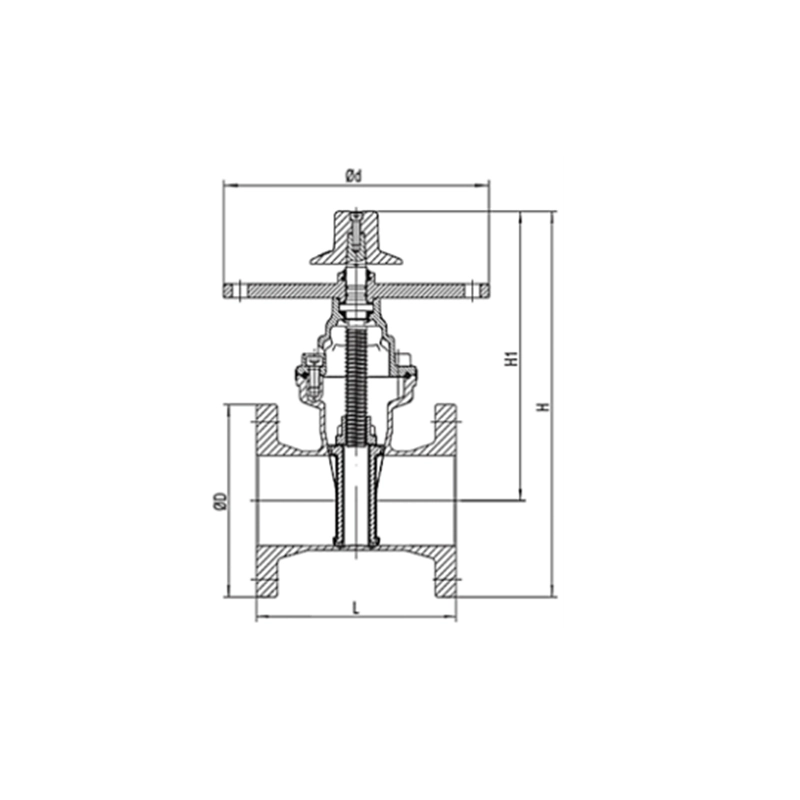

Válvula de compuerta NRS de asiento elástico con bridas y poste indicador

Flanged Resilient Seated NRS Gate Valve with Indicator Post Definition and Components

A standard resilient seated nrs gate valve with post indicator extension that shows valve position (open/closed) from ground level when buried. Model Z45X-04: Z=gate valve, 45=flanged, X=resilient seat, 04=with indicator post version.

Main Parts:

Standard Valve Components: Body, gate, stem, bonnet, flanges

Indicator Post Extension: Steel pipe extension (typically 2-6 ft)

Position Indicator: Visual display at top showing open/closed

Tee Handle or Operating Nut: For operation from ground level

Protective Cover: Weatherproof cap for indicator post

Buried Service Package: Extended stem, protected components

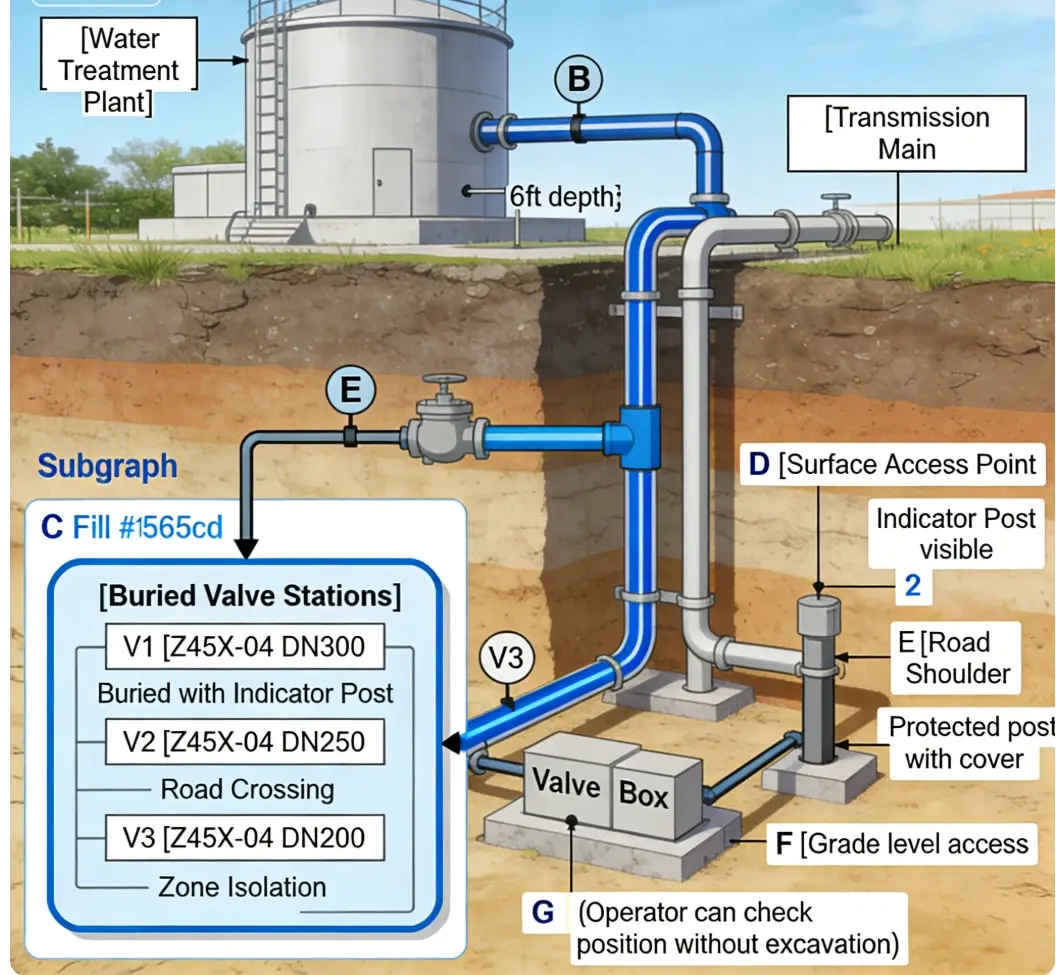

Role, Characteristics, and Application Scenarios of Flanged Resilient Seated NRS Gate Valve with Indicator Post in Pipelines

Functions:

Underground pipeline isolation with above-ground operation

Valve position indication without excavation

Corrosion protection for buried installations

Easy access for maintenance and operation

Fire valves Operational Features:

Ground-level operation - no digging required

Visual position indicator - clear open/closed status

Extended stem - connects buried valve to surface

Weatherproof design - suitable for outdoor burial

Lockable cap - for security and tamper prevention

Fire gate valve Typical Applications:

Buried water distribution lines

Underground fire protection systems

Subsurface irrigation control

Municipal utility vaults

Industrial buried piping

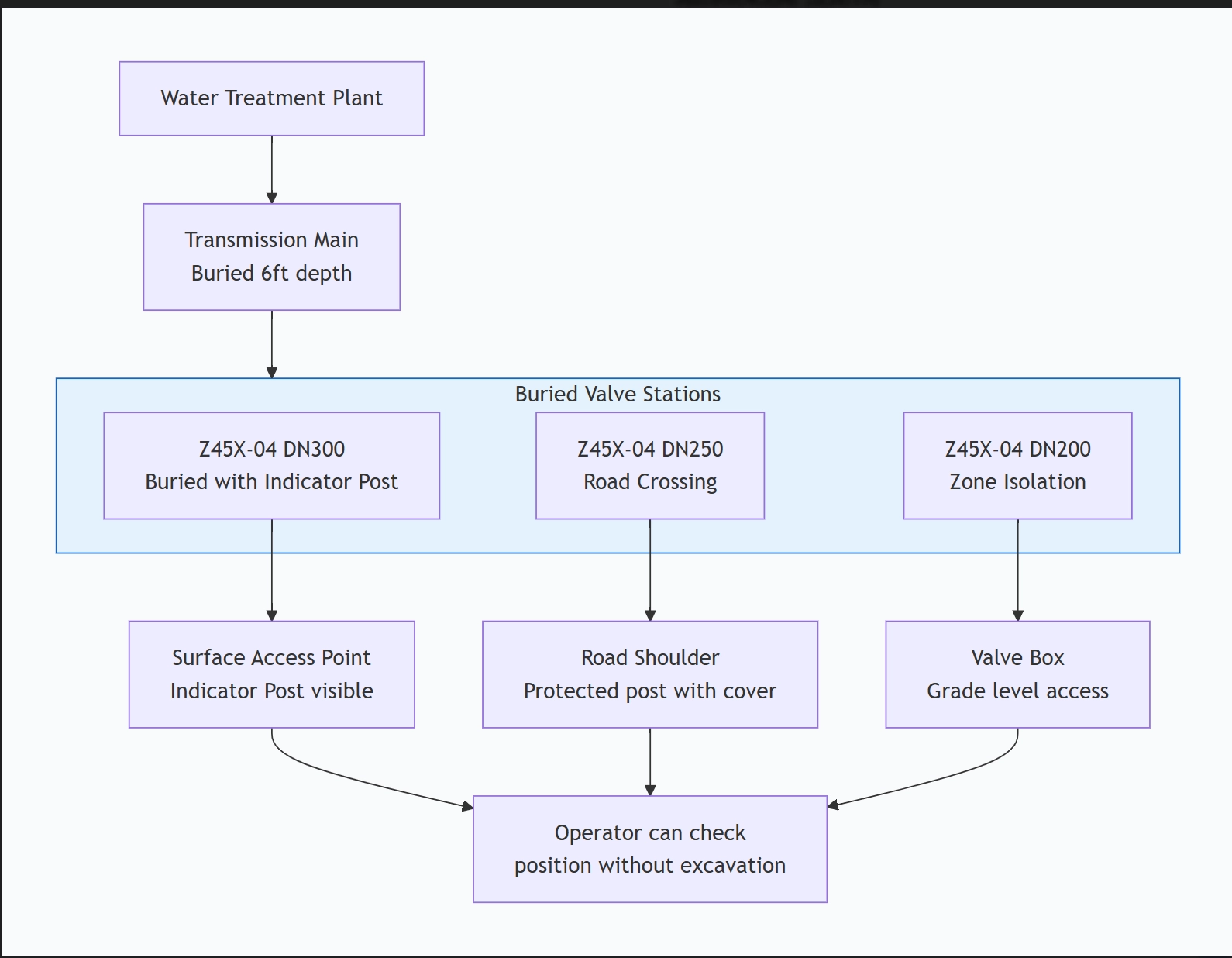

Scenario Diagram:

Flanged Resilient Seated NRS Gate Valve with Indicator Post Standards: Materials, Design, and Connections

Material Standards:

Body/Bonnet: Ductile iron ASTM A536

Stem (Extended): Stainless steel AISI 304/316

Indicator Post: Galvanized steel pipe ASTM A53

Protective Coating: Fusion-bonded epoxy or hot-dip galvanized

Indicator Mechanism: Brass/stainless steel components

Design Standards:

Valve: AWWA C509 or ISO 5208

Buried Service: AWWA C550 for coatings

Indicator Post: Manufacturer standard (typically 2" or 3" pipe)

Extension Length: Customizable (typically 2-6 feet)

Operating Torque: Designed for extended stem operation

Connection Standards:

Flanges: ANSI B16.1 Class 125/250 or EN 1092-2 PN10/16

Post Connection: Threaded or bolted to valve bonnet

Surface Fitting: Standard tee handle or nut driver

Protective Cover: Lockable, weather-resistant design

Additional Standards:

Corrosion Protection: ISO 12944 for buried applications

Potable Water: NSF/61 compliant materials

Load Rating: Traffic-rated covers for road applications

How to Select Flanged Resilient Seated NRS Gate Valve with Indicator Post

Key Steps:

Specify Requirements:

Valve size and pressure rating

Indicator post length (critical dimension)

Burial depth requirements

Surface fitting type (tee handle, nut, wheel)

Locking mechanism requirements

Special Considerations:

Extension length from valve centerline to grade

Traffic loading if under roadways

Corrosion protection level for soil conditions

Position indicator type (visual, lockable)

Supplier Requirements:

Experience with buried valve packages

Custom fabrication capability for extensions

Corrosion protection expertise

AWWA/ISO compliance

Documentation Needed:

Custom drawing approval (showing post length)

Coating specifications for buried service

Installation instructions for buried valves

Critical Specifications:

Post length: ______ (from valve center to grade)

Surface fitting: Tee handle / Operating nut / Wheel

Lock type: Standard / High security

Cover: Flush mount / Raised / Traffic-rated

Coating: Epoxy / Galvanized / Dual protection

Pre-Shipment Inspection for Export Flanged Resilient Seated NRS Gate Valve with Indicator Post and Key Considerations

Inspection Focus Areas:

Indicator Post Assembly:

Verify extension length matches specifications

Check post vertical alignment

Test indicator mechanism (smooth operation)

Verify position accuracy (open/closed indication)

Buried Service Components:

Coating thickness and coverage

Weld quality on extensions

Thread protection on exposed threads

Weatherproofing of indicator mechanism

Special Tests:

Extended stem operation test - torque measurement

Indicator accuracy test - position verification

Weatherproof test - seal integrity of cover

Load test - for traffic-rated covers

Export Precautions:

Long components: Special crate design for post extensions

Delicate indicators: Extra padding for visual indicators

Multiple pieces: Clearly mark all components for assembly

Installation guide: Detailed instructions for buried installation

Documentation Package:

Assembly drawings with dimensions

Coating certificates for buried service

Torque specifications for extended operation

Burial installation instructions

Maintenance manual for indicator mechanism

Field Verification Requirements:

Before shipment, verify:

Post length matches burial depth requirements

Indicator shows correct valve position

Surface fitting compatible with local tools

All components suitable for soil conditions at destination

Flanged Resilient Seated NRS Gate Valve with Indicator Post Size Chart

.png)

.png)