Rising Resilient Seat Gate Valve Z41X

Rising Resilient Seat Gate Valve Z41X Purpose

This valve is mounted on various pipelines and used as a bi-way closed circuit equipment for tap water, sewage treatment, metallurgy, petroleum, building, chemical, electric power industries etc.

Rising Resilient Seat Gate Valve Z41X Definition and Components

The Z41X is a Rising Stem, Flanged, Resilient-Seated Gate Valve. The designation breaks down as: Z (Gate Valve), 4 (Flanged Ends), 1 (Rising Stem - Outside Screw & Yoke/OS&Y design), X (Resilient/Rubber Seal). Its defining feature is the stem that rises above the handwheel when the valve opens, providing a clear visual indication of the valve's position.

Partes principales:

- Valve Body: Main pressure-containing part with integral flanges.

- Bonnet: Bolted cover that provides access to internals.

- Rising Stem: Stainless steel stem with external threads. It rises/falls visibly.

- Yoke & Yoke Nut: Framework supporting the stem. The nut engages the stem threads.

- Resilient Gate: A metal disc fully encapsulated in rubber (EPDM, NBR) for sealing.

- Seat Rings: Machined rings in the body against which the gate seals.

- Packing System: Seals (e.g., graphite rings) around the stem to prevent leakage.

- Handwheel: For manual operation.

Role, Characteristics, and Application Scenarios of Rising Resilient Seat Gate Valve Z41X in Pipelines

Funciones de canalización:

- Positive, Visual Isolation: Provides complete shut-off. The stem position gives an immediate, unambiguous "open" or "closed" status from a distance.

- Full-Bore Flow: Minimal pressure drop when fully open.

- Bidirectional Sealing: Effective in either flow direction.

- Easy Maintenance: External threads are accessible for inspection and lubrication.

Características operativas:

- Visual Position Indication: The key safety feature. No guessing valve status.

- Protected Mechanism: Stem threads are outside the flow media, preventing corrosion and wear from the fluid.

- Higher Torque Capability: Robust OS&Y design handles higher operating torques than non-rising stem designs.

- Requires More Space: Needs vertical clearance for the stem to rise fully.

fire protection water supply Escenarios de aplicación:

Used where visual confirmation of valve status is critical for safety or operational procedure. Common in:

- Fire Protection Systems: As main isolation valves for sprinkler systems. Inspectors must visually verify "open" status.

- Water Treatment & Distribution: At pump suction/discharge, tank inlets/outlets, and critical isolation points in treatment plants.

- Industrial Plants: For isolating equipment (pumps, heat exchangers) where safe maintenance requires a visibly closed valve.

- Steam Lines (Low Pressure): For isolation, though temperature limits of the rubber seat must be observed.

Diagrama del escenario (Descripción del texto):

In a fire pump room, a Z41X valve is installed on the main supply line before the pump. Its rising stem allows the facility manager or fire inspector to instantly confirm from the room entrance that the valve is fully open, ensuring water supply to the sprinkler system is not accidentally blocked. A second Z41X valve on the pump discharge side provides a visible isolation point for pump maintenance. This setup contrasts with areas where space is limited (like underground vaults), where a non-rising stem (Z45X) valve might be used instead.

Rising Resilient Seat Gate Valve Z41X Standards: Materials, Design, and Connections

Normas materiales:

- Body/Bonnet: ASTM A126 (Cast Iron), ASTM A216 WCB (Carbon Steel), ASTM A351 CF8 (304 SS).

- Stem: ASTM A276 Type 304/316 Stainless Steel.

- Gate/Seat: Cast iron + EPDM/NBR/Viton per NSF/ANSI 61 for potable water.

- Bolting: ASTM A193 B7/B16.

Normas de diseño:

- API 600: Primary standard for steel gate valves.

- API 603: For corrosion-resistant valves.

- ASME B16.34: Valve pressure-temperature ratings.

- ISO 5208: Pressure testing requirements.

- MSS SP-70: For cast iron gate valves.

Normas de conexión:

- Flanges: ASME B16.5 Class 150/300 (RF faces), EN 1092-1 PN10/PN16/PN25.

- Face-to-Face: Dimensions per ASME B16.10 or ISO 5752.

How to Select Rising Resilient Seat Gate Valve Z41X

Válvula de compuerta para agua Pasos clave:

Define Specifications Clearly:

- Service: Fluid, temperature (max/min), pressure (operating/design).

- Materials: Specify body, trim, and seat elastomer based on fluid compatibility (e.g., EPDM for water, Viton for hydrocarbons).

- Design: Pressure Class (e.g., 150, 300), flange standard, face-to-face dimension.

- Critical Requirement: Always specify "Rising Stem (OS&Y) design."

- Evaluate Suppliers: Check for relevant quality certifications (ISO 9001) and experience in manufacturing to API/ASME standards. Request material certifications and test procedures.

- Review Documentation: Ensure purchase orders require material test certificates (MTCs per EN 10204 3.1), pressure test reports, and detailed drawings for approval.

- Focus on Total Cost: Consider lifecycle cost, not just purchase price. The maintainability and reliability of the OS&Y design often justify a higher initial cost for critical applications.

Pre-Shipment Inspection for Export Rising Resilient Seat Gate Valve Z41X and Key Considerations

Lista de comprobación de la inspección:

- Visual & Dimensional: Check for damage, verify flange dimensions/drilling, ensure markings (size, pressure rating, material) are clear per MSS SP-25.

- Functional Test: Operate valve fully open/closed. Ensure stem rises and falls smoothly without binding. Verify position indicator is accurate.

Pressure Tests (Per API 598/ISO 5208):

- Shell Test: Apply 1.5x rated pressure to the body with gate open. No leakage permitted.

- Seat Test: Apply 1.1x rated pressure with valve closed, first from one direction, then the other. For resilient seats, zero visible leakage is required.

- Documentation: Verify all certificates (material, test) are complete and match the valve serial number.

Fire Protection Valves and Fittings Precauciones para la exportación:

- Preservation: Drain all test water completely. Apply a light, protective oil or VCI (Vapor Corrosion Inhibitor) to machined surfaces (flange faces, stem threads).

- Protection: Fit sturdy plastic or metal covers bolted onto flange faces. Protect the exposed stem threads with a plastic cap or heavy grease and wrapping.

- Packaging: Secure the valve in a sturdy, wooden export crate (ISPM-15 compliant for international shipment) with internal blocking to prevent movement. The handwheel should be locked or secured.

- Documentation: Place a complete set of inspection certificates, test reports, and manuals in a waterproof pouch inside the crate. Ensure shipping marks are clear on the outside.

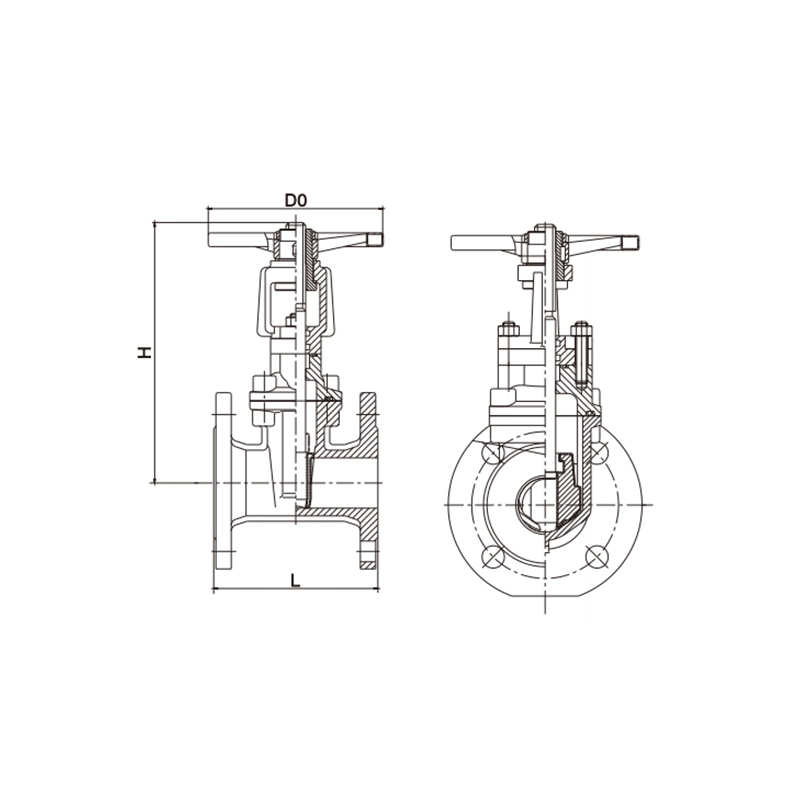

Rising Resilient Seat Gate Valve Z41X Main dimensions(mm)

| DN | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 700 | 800 | |

|

L

|

GB | 178 | 190 | 203 | 229 | 254 | 267 | 292 | 330 | 356 | 381 | 406 | 432 | 457 | 508 | 605 | 665 |

| DIN | 150 | 170 | 180 | 190 | 200 | 210 | 230 | 250 | 270 | 290 | 310 | 330 | 350 | 390 | 430 | 470 | |

| D0 | 180 | 180 | 230 | 230 | 280 | 280 | 330 | 380 | 380 | 380 | 480 | 480 | 600 | 600 | 800 | 800 | |

| H max | 314 | 335 | 400 | 430 | 582 | 605 | 730 | 938 | 1010 | 1460 | 1660 | 1900 | 2120 | 2400 | 3000 | 3200 | |

Nota:1. Otras especificaciones y normas de brida disponibles bajo pedido.

- El diseño y las especificaciones están sujetos a cambios sin previo aviso.

.png)

.png)