Fire Department Connection

Fire Department Connection Definition and Components

A Fire Department Connection (FDC), often called a "Siamese Connection," is a critical exterior inlet installed on buildings to allow fire departments to supplement a building's fixed fire suppression system (like sprinklers or standpipes) with water and pressure from fire engines.

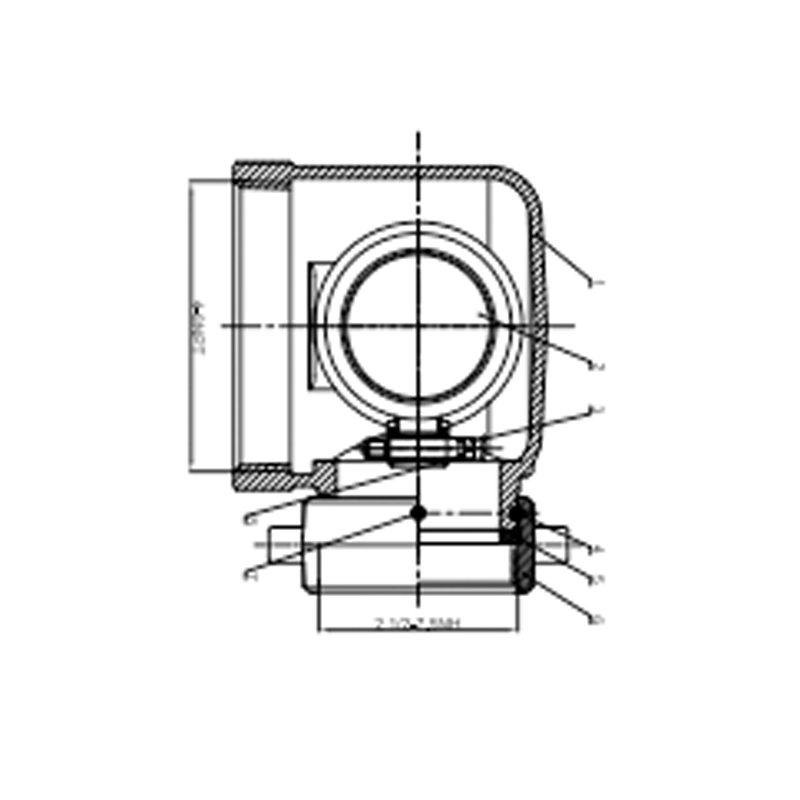

Main Parts:

- Inlet Swivel(s): One or more swiveling female-threaded connections (or quick-couplers) for fire hoses. They allow hoses to connect at various angles.

- Check Valves (Clappers): Individual swing-type check valves behind each inlet to prevent water from flowing backward out of the inlets.

- Body / Hub: The central manifold that combines the flows from the inlets into a single outlet.

- Outlet Pipe: The connection from the body to the building's fire protection system riser. Typically a threaded or flanged connection.

- Protective Caps / Chains: Removable, threaded caps for each inlet to keep out debris, insects, and water. They are attached with chains to prevent loss.

- Identification Plate / Plaque: A durable metal sign labeling the system type (e.g., "AUTOSPKR" for automatic sprinkler, "STANDPIPE") and sometimes pressure requirements.

Role, Characteristics, and Application Scenarios of Fire Department Connection in Pipelines

Functions in Pipelines:

- Pressure & Flow Boost: The primary function is to allow fire department pumpers to boost the pressure and flow in a building's fire suppression system, overcoming pressure losses and ensuring adequate performance at the sprinkler heads or hose valves.

- Emergency Water Supply: Provides a crucial secondary water supply if the building's primary water source (tank, pump, city main) is compromised.

- System Testing: Used during annual flow tests to supply water without activating internal pumps or draining storage tanks.

Operational Features:

- Multiple Inlets: Typically 2 (dual) or more inlets, allowing multiple fire hoses to be connected for greater water volume.

- Thread Standardization: Inlets have standard fire hose threads (e.g., NST) specific to the local fire department's equipment.

- Automatic Check Valves: Prevent system water from discharging out the inlets and allow individual hoses to be connected under pressure.

- Freestanding or Wall-Mount: Designed for clear, accessible installation near building entrances or fire lanes.

Fire Department Connection Standards: Materials, Design, and Connections

Brass Valves Material Standards:

- Body & Hubs: ASTM A536 Ductile Iron (standard) or Bronze (ASTM B584). Exterior is typically red epoxy-coated.

- Check Valve Components (Clappers, Springs): Stainless Steel (AISI 304/316) or Bronze.

- Swivel Inlets: Forged Brass or Bronze for corrosion resistance and smooth operation.

- Caps: Aluminum or Brass, with rubber gaskets.

Design & Performance Standards:

- UL 405 (US) / FM 2020 (US): The key standards for Fire Department Connections. They govern design, performance (flow/pressure drop), durability, and marking.

- NFPA 13 & NFPA 14: The installation standards that dictate FDC location, sizing, labeling, and the required number of inlets based on system size.

- Hydrostatic Pressure Rating: Standard working pressure is typically 175 psi or 250 psi.

- Connection Standards:Inlet Threads: NST (National Standard Thread) is most common in the US. NH (National Hose) threads are also used. The specific thread type (e.g., 2.5" NST) must match the local fire department's hose couplings. Other regions use BSP or Storz quick-connect.

- Outlet Connection: Typically a threaded (NPT) or flanged connection to mate with the building's underground or interior piping.

How to Select Fire Department Connection

Purchasing Guide:

Define Specifications Based on System Design:

- Number of Inlets: Usually 2 (for systems up to 1000 GPM). Larger systems may require 3 or 4 (per NFPA 13).

- Inlet Thread Type & Size: This is critical. Consult the local Authority Having Jurisdiction (AHJ) or fire marshal to confirm the required thread (e.g., 2.5" NST). Do not guess.

- Outlet Size & Type: Must match the connecting pipe on the building plans (e.g., 4" NPT).

- Pressure Rating: Standard is 175 psi WP. Specify higher if required by system design.

Verify Mandatory Certifications:

- The FDC assembly must be UL Listed (UL 405) or FM Approved (FM 2020). This certification is legally required by building codes.

- Request the official listing page or certification guide.

Fire Valves Supplier Selection & Sourcing:

- Source from specialized fire protection manufacturers or their authorized distributors.

- Provide a detailed data sheet including: Inlet Qty/Thread, Outlet Size/Type, Material, and required plaque text.

- For export projects, confirm the supplier can provide certification documents acceptable in the destination country.

.png)

.png)