Flanged Swing Check Valve Model No. H44X

Flanged Swing Check Valve Model No. H44X Definition and Components

A Flanged Swing Check Valve Model No. H44X is a type of automatic, self-activating valve designed to allow fluid flow in one direction only and prevent reverse flow (backflow). The model number "H44X" is a common designation where "H" signifies a check valve, "4" indicates flanged connection, the second "4" represents the swing or tilting disc design, and "X" denotes a resilient (rubber) seat.

Flanged Check Valve Fire Protection Key Terminology:

- Flanged Ends:The valve features integral flanges for bolted connection to the pipeline, providing a strong, leak-tight joint suitable for a wide range of pressures.

- Swing Type:The closure member (disc) is hinged at the top and swings open or closed on a pivot pin. It opens with forward flow and closes by gravity and backflow pressure.

- Resilient Seat:Incorporates an elastomer (e.g., NBR, EPDM) sealing ring on the disc or within the seat, enabling bubble-tight sealing with low closing impact.

Main Parts:

- Valve Body (with integral flanges and flow chamber)

- Cover/Bonnet (Provides access to internal parts, bolted to the body)

- Disc (The swinging closure member)

- Hinge Arm/Pin Assembly (Allows the disc to pivot freely)

- Resilient Seat Ring (Mounted in the body, provides sealing surface for the disc)

- Disc Nut/Retainer (Secures the disc to the hinge arm)

- Gasket (Between body and cover)

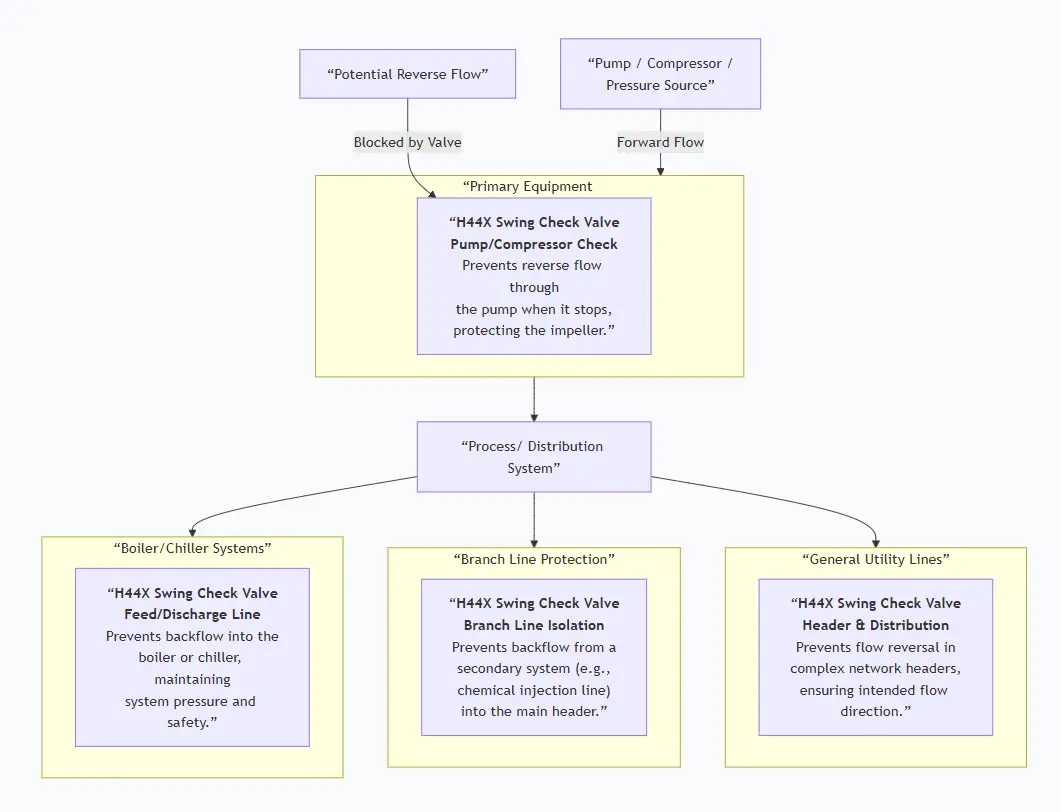

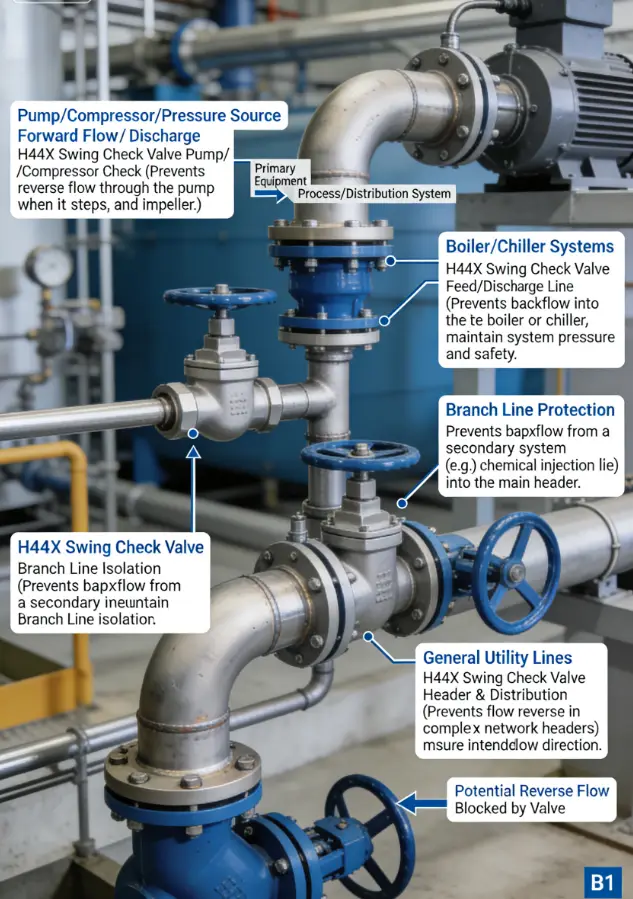

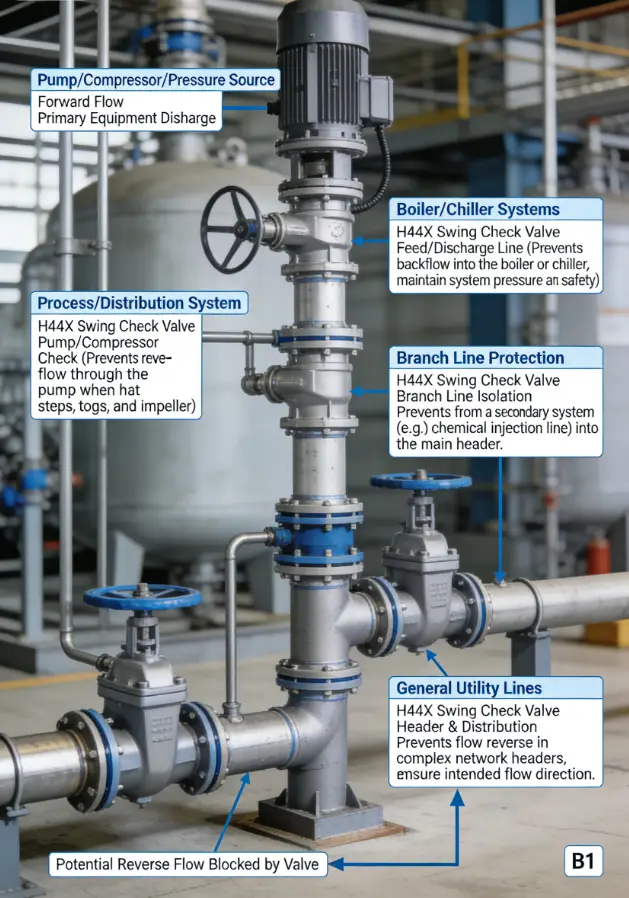

Role, Characteristics, and Application Scenarios of Flanged Swing Check Valve Model No. H44X in Pipelines

Functions:

- Backflow Prevention:Primary function is to automatically prevent reverse flow in a pipeline.

- Equipment Protection:Protects pumps, compressors, and other equipment from damage caused by reverse flow.

- Contamination Prevention:Maintains system integrity by preventing mixing of different media from connected systems.

Operational Features:

- Fully Automatic Operation:Requires no external actuator; operates solely based on flow dynamics.

- Low Flow Resistance:In the fully open position, the disc swings clear of the flow path, minimizing pressure drop.

- Gravity & Flow-Assisted Closing:Closes under its own weight (when installed horizontally) and is aided by reverse flow.

- Slam Prevention (Potential Issue):Traditional swing checks can "slam" shut, causing water hammer. Model H44X's resilient seat can dampen this, but for critical applications, a "non-slam" or "silent" check valve design is preferred.

- Installation Orientation:Must be installed in a horizontal position with the hinge pin horizontal to ensure proper disc swing and gravity-assisted closure. Vertical installation requires a specific spring-assisted design.

Fire Check Valve Primary Usage Scenarios:

This valve is ubiquitous in systems where reverse flow must be prevented. It is common in water supply, HVAC, industrial process lines, and general plant utilities. It is not ideal for pulsating flows or where rapid, violent closure (slam) must be avoided.

Scenario Diagram:

Flanged Swing Check Valve Model No. H44X Standards: Materials, Design, and Connections

How to Select Flanged Swing Check Valve Model No. H44X

Step 1: Define Technical Specifications

Precise specifications prevent improper selection and installation.

- Service Conditions:Fluid, max/min temperature, and operating pressure. Specify if pulsating flow is expected.

- Size & Pressure Class:Nominal Diameter (e.g., 10") and Flange Pressure Class (e.g., ASME B16.5 Class 150, PN16).

- Materials:Body material (e.g., WCB Carbon Steel), seat/disc material (e.g., Ductile Iron + NBR Rubber), hinge pin material (e.g., Stainless Steel).

- Design Standard:Explicitly require design per API 594.

- Special Requirements:Note if a lever & weight or spring accessory is needed for vertical installation or to modify closing speed.

Step 2: Source and Evaluate Suppliers

- Source from general industrial valve manufacturers. Quality can vary significantly based on foundry and assembly practices.

- Request detailed product data sheets confirming dimensions (especially face-to-face), weight, and materials.

- For critical services, request design calculations or CFD analysis for flow resistance and closing dynamics.

Step 3: Order Execution

- These are standard items. Confirm lead times for specific material grades.

- Required docs: Commercial Invoice, Packing List, Certificate of Compliance, and Material Test Reports (MTRs) for the pressure-retaining parts (body, cover).

Pre-Shipment Inspection for Export Flanged Swing Check Valve Model No. H44X and Key Considerations

Fire Fighting Valve Inspection Checklist:

Key Precautions for Export:

- Immobilize the Disc:This is the single most important step. Use a wooden block, plastic clamp, or strong nylon strap to securely hold the disc against the seat. This protects the hinge mechanism and seat from impact damage.

- Heavy-Duty Crating:Flanged valves are heavy. Use robust timber crates with adequate internal bracing to handle the weight. Clearly mark the center of gravity and lifting points on the crate.

- Internal VCI Protection:Apply a volatile corrosion inhibitor (VCI) spray or gel to all internal and machined surfaces (hinge pin, bore) before closing the valve for shipment.

- Separate Gasket Kit:Pack the body-cover gasket and any fasteners in a small bag and attach it securely inside the crate, not loose in the valve bore.

- Orientation Marking:Clearly mark the crate with "KEEP HORIZONTAL" and "FLANGE FACES UP" (if applicable) to prevent improper handling that could dislodge the disc block.

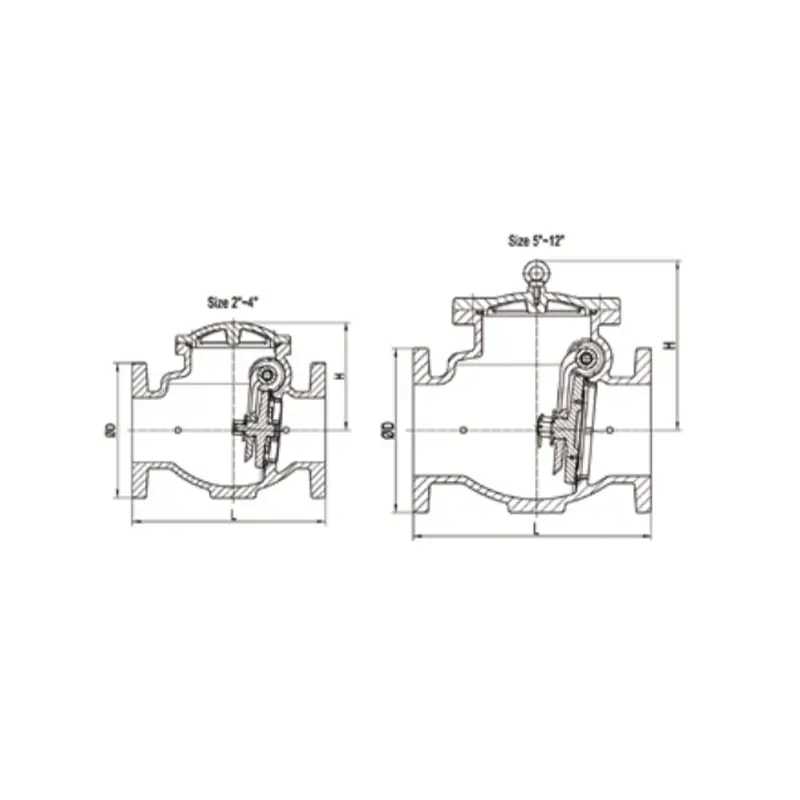

Flanged Swing Check Valve Model No. H44X Size Chart

| Dimensions | Pressure rating | Size(mm) | |||

| DN | inch | Psi | Ф D | L | H |

| 50 | 2 | 300 | 152 | 203 | 125 |

| 65 | 2.5 | 300

|

178

|

254 | 139 |

| 80 | 3 | 300 | 191 | 279 | 153 |

| 100 | 4 | 300 | 229 | 330 | 184 |

| 125 | 5 |

300 |

254 | 356 | 275 |

| 150 | 6 |

300 |

279 | 406 | 289 |

| 200 | 8 | 300 | 343 | 496 | 352 |

| 250 | 10 | 300 | 406 | 559 | 411 |

| 300 | 12 | 300 | 483 | 660 | 480 |

.png)

.png)