Full Welded Full Bore Ball Valve 061F

Full Welded Full Bore Ball Valve Purpose

The Ball Valve Full Bore in the pipeline is mainly used for cutting equipment use,widely used in perochemial ,power station,metallurgy and other industrial fluid pipe, can also be used for oxygen,hydrogen peroxide ,methane and ethlene gas pipeline etc.

Full Welded Full Bore Ball Valve Definition and Components

What is a Full Welded Full Bore Ball Valve 061F and its main parts?

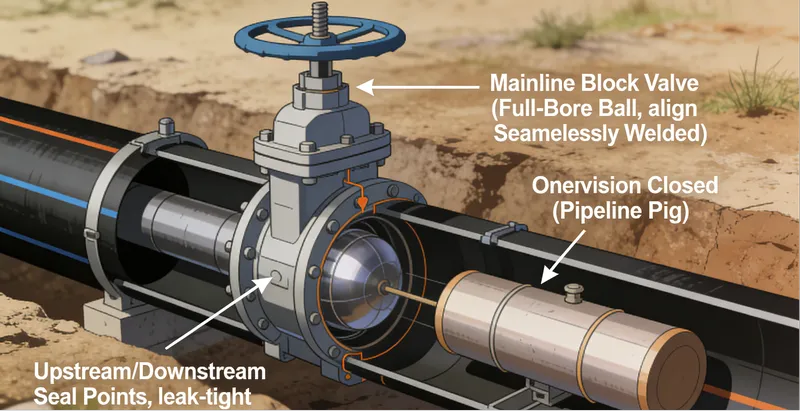

A Full Welded Full Bore Ball Valve 061F is a high-integrity, permanent pipeline valve designed for critical service. The "Full Welded" construction means the valve body is created by welding together forged or cast sections (typically two hemispheres and a centerpiece), resulting in a lightweight, leak-proof body with no bolted flanges or gaskets. "Full Bore" means the internal diameter of the ball's port matches the internal diameter of the connecting pipeline, ensuring minimal pressure drop and allowing for pipeline pigging.

Full Bore Ball Valve Main Parts:

- Welded Body Assembly: The main pressure-containing structure, formed by welding together precision components. This is the defining feature.

- Ball: A spherical component with a through-hole (bore), often chrome-plated or coated for hardness and corrosion resistance.

- Stem: A shaft connected to the ball and the actuator, transmitting the opening/closing torque. Features a blow-out-proof design.

- Seats: Upstream and downstream sealing rings (often PTFE, reinforced PTFE, or metal) that provide a tight seal against the ball.

- Primary Seals & Stem Seals: Advanced sealing systems (e.g., graphite, PTFE) for stem and body sealing, suitable for high temperatures/pressures.

- Actuator Mounting Pad: A standardized interface (ISO 5211) for mounting pneumatic, hydraulic, or electric actuators.

- Butt-Weld Ends: Prepared pipe ends for direct, permanent welding into the pipeline.

Role, Characteristics, and Application Scenarios of Full Welded Full Bore Ball Valve in Pipelines

Functions, Operational Features, Usage Scenarios, and Scenario Diagram

Functions: Provides reliable, permanent on/off isolation in pipelines. Its primary roles are zero-leakage shut-off, unrestricted full-bore flow, and long-term, maintenance-free service in inaccessible locations.

Operational Features:

- Permanent Leak Integrity: The welded body eliminates potential leak paths from body gaskets and flange bolts.

- Quarter-Turn Operation: Fast 90-degree operation for quick open/close.

- Low Maintenance & Long Life: Designed for the entire service life of the pipeline with minimal intervention.

- Lightweight & Compact: Compared to flanged valves of the same rating, it is lighter and requires less space.

- Piggable: The full-bore design allows inspection and cleaning pigs to pass through.

- Usage Scenarios: Employed in severe, high-risk, or inaccessible applications where reliability is paramount.

- Mainline Transmission Pipelines: For natural gas, crude oil, and refined products.

- Subsea Pipelines & Offshore Platforms: Where reliability and space/weight are critical.

- Buried Pipelines: For city gas distribution, district heating, and water mains where access is difficult.

- Nuclear, Power, & Process Plants: In high-pressure/temperature critical lines.

- Arctic & Severe Environments: Where thermal cycling and extreme conditions exist.

Full Welded Full Bore Ball Valve Standards: Materials, Design, and Connections

Material, Design, and Connection Standards

Water Valves Material Standards:

- Body & Ball Forgings: ASTM A105 (Carbon Steel), ASTM A182 F316/F304 (Stainless Steel), ASTM A182 F51/F53 (Duplex/Super Duplex).

- Seats & Seals: PTFE, RPTFE, PEEK, Metal (Inconel, Stainless Steel).

- Stem: 17-4PH, ASTM A182 F6a, F316.

- Design Standards: Primarily API 6D (Pipeline Valves) or ISO 17292 (Petroleum and natural gas industries). It also conforms to pressure-temperature ratings per ASME B16.34.

- Connection Standards: The ends are prepared for butt-welding as per ASME B16.25. This standard defines the bevel angle, land, and taper for welding directly to pipeline pipes of matching material and wall thickness (e.g., API 5L line pipe)

How to Select Full Welded Full Bore Ball Valve

How to Purchase

- Specify Precise Requirements: Define critical parameters: Size (NPS/DN), Pressure Class (e.g., ASME Class 600, 900), Fluid Media (including composition, temperature), Material Grade (e.g., A105, F316), Actuation Requirements, and any special needs (Fire-Safe per API 607/6FA, Anti-static device, Extended stem for burial).Source Qualified Manufacturers: Target reputable, specialized valve manufacturers with API 6D monogram licensing and proven experience in pipeline projects. Quality management (ISO 9001) and specific product certifications are essential.

- Request Detailed Quotation & Technical Documentation: Submit a detailed inquiry. Request a formal quote with a comprehensive technical data sheet, material specifications, welding procedure specifications (WPS), and certified dimensional drawings.

- Review and Place Order: Evaluate bids based on technical compliance, certification validity, lead time, cost, and warranty. The purchase order must explicitly reference all standards (API 6D, ASME B16.34, etc.), material grades, test requirements, and documentation deliverables.

Pre-Shipment Inspection for Export Full Welded Full Bore Ball Valve and Key Considerations

Pre-Export Inspection and Precautions

- Inspection Protocol (Witnessed or Documentary Review):

- Dimensional & Visual Check: Verify dimensions against drawings, inspect weld quality on the body, and check for damage.

- Material Traceability: Review Material Test Reports (MTRs) for all pressure-containing parts, verifying heat numbers and compliance with specified grades.

- Weld Procedure Review: Confirm WPS and welder qualifications are available.

- Witness Pressure Tests: Critical to witness or review records of Shell Test, Seat Leakage Test (both directions), and Stem Backseat Test performed strictly per API 6D standards. This often includes low-pressure and high-pressure seat tests.

- Actuator Function Test (if fitted): Verify operation and setting of torque limits.

- Coating & Packaging Inspection: For external coating (e.g., FBE, 3LPE) per pipeline standards. Check that weld ends are protected with durable plastic caps, and the valve is securely crated.

Precautions:

- Protect Weld Bevels: The beveled weld ends are critical and must be protected from impact, moisture, and corrosion with sturdy, tightly fitted caps.

- Valve Position: Ship in the fully open position to relieve seat stress.

- Documentation Package: Ensure a complete "Data Book" is supplied, including MTRs, test reports, certificates of conformity, assembly drawings, and maintenance instructions.

- Shipping: Clearly mark crates with handling instructions, identification, and "Protect Weld Ends" warnings. Ensure crating is robust for ocean freight.

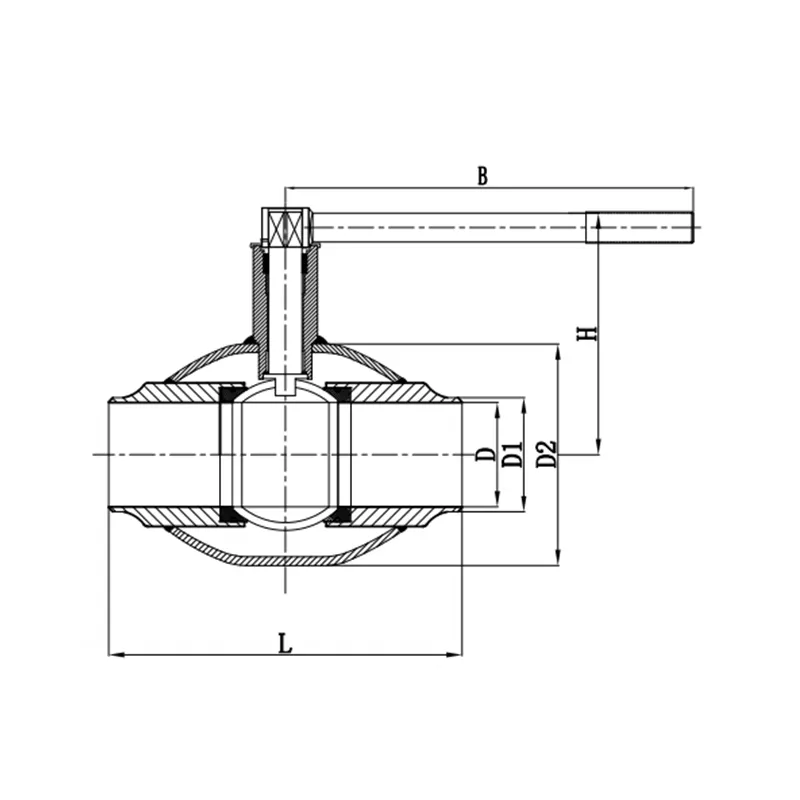

Full Welded Full Bore Ball Valve Main dimensions(mm)

| DN | L | H | D2 | D1 | D2 | B |

| 25 | 230 | 76 | 20 | 34 | 48 | 159 |

| 32 | 260 | 85 | 25 | 42 | 60 | 159 |

| 40 | 260 | 95 | 32 | 48 | 70 | 245 |

| 50 | 300 | 124 | 40 | 60 | 83 | 245 |

| 65 | 300 | 162 | 50 | 76 | 102 | 320 |

| 80 | 300 | 175 | 65 | 89 | 140 | 320 |

| 100 | 325 | 192 | 80 | 108 | 168 | 450 |

| 125 | 350 | 205 | 100 | 133 | 203 | 450 |

| 150 | 400 | 225 | 125 | 159 | 219 | 450 |

| 200 | 520 | 275 | 150 | 209 | 270 | 450 |

Note:1. Other specifications and flange standards are available upon request.

- Design and specifications are subject to change without prior notice.

.png)

.png)