Gost Stainless Steel Gate Valve

Gost Stainless Steel Gate Valve Definition and Components

What is a GOST Stainless Steel Gate Valve and its main parts?

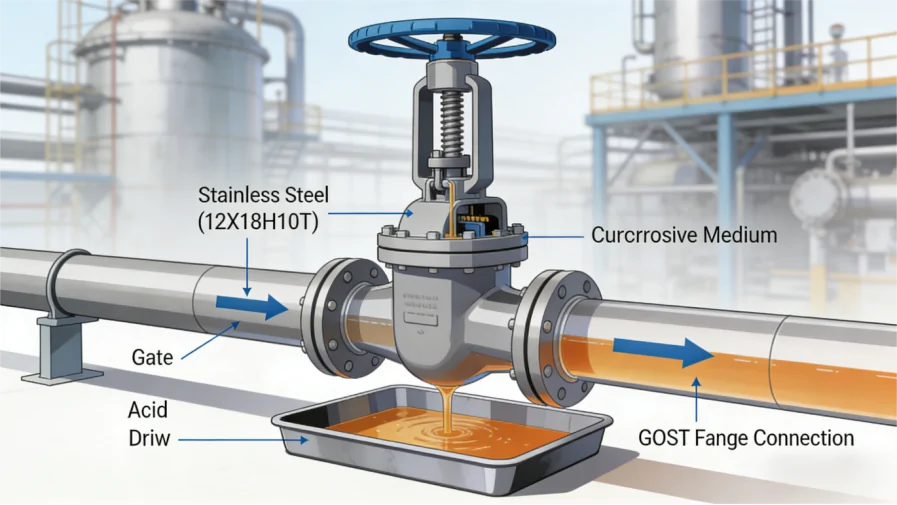

A GOST Stainless Steel Gate Valves is a valve designed and manufactured according to the standards of the GOST system (primarily used in Russia, CIS, and some Eastern European countries), with its primary pressure-containing and wetted parts constructed from corrosion-resistant stainless steel alloys. It combines the stringent design, testing, and documentation requirements of GOST with the material properties needed for corrosive, high-purity, or low-temperature services.

Main Parts:

- Body & Bonnet: The main casting or forging, made from GOST-standard stainless steel grades such as 12X18H10T (similar to AISI 321) or 08X18H10T (similar to AISI 304Ti). The bonnet is typically bolted.

- Gate/Wedge: The closure element, also made of stainless steel. It can be a solid, flexible, or split wedge design.

- Stem: A rising stem (OS&Y type) made from stainless steel (e.g., 20X13 or 14X17H2).

- Seat Rings: The sealing surfaces. They are often made of hardened stainless steel or stellite-faced stainless steel, pressed or welded into the body.

- Yoke & Yoke Sleeve/Bushing: The assembly that houses the stem threads and connects to the actuator.

- Packing Box: Contains stem packing (often graphite for high-temperature service) and a gland follower to prevent external leakage.

- Handwheel or Gear Operator: For manual operation.

- Flanges: Connection ends conforming to GOST flange standards (e.g., GOST 12815, GOST 33259).

Role, Characteristics, and Application Scenarios of Gost Stainless Steel Gate Valve in Pipelines

Functions, Operational Features, Usage Scenarios, and Scenario Diagram

Industrial valves Functions: Provides reliable on/off isolation in pipelines carrying corrosive, chemically aggressive, high-purity, or cryogenic media. It ensures a tight seal when closed and minimal flow restriction when fully open.

Operational Features:

- Corrosion Resistance: The primary feature, suitable for acids, alkalis, salt solutions, and other aggressive chemicals within the material's limits.

- Cryogenic Capability: Certain austenitic stainless grades (like 12X18H10T) retain toughness at very low temperatures, making them suitable for LNG, liquid nitrogen, or oxygen services (with proper cleaning).

- High-Temperature Resistance: Good oxidation resistance at elevated temperatures.

- Hygienic/Sanitary Potential: With proper surface finish (electropolishing), can be used in food, pharmaceutical, or high-purity water applications.

- Slow Operation: Standard multi-turn design, not for quick shut-off.

Usage Scenarios:

- Chemical & Petrochemical Plants: For transporting acids, caustics, solvents, and process intermediates.

- Fertilizer & Pharmaceutical Industries.

- Food & Beverage Processing (with appropriate surface finish and certification).

- Cryogenic & LNG Facilities: Liquid gas transfer lines.

- Marine & Offshore: Sea water cooling systems, ballast lines.

- Power Plants: Demineralized water or chemical dosing lines.

Gost Stainless Steel Gate Valve Standards: Materials, Design, and Connections

Material, Design, and Connection Standards

This valve is defined by a strict adherence to GOST standards for both design and material.

Material Standards (GOST):

- Body/Bonnet: GOST 5632 grades are used. Common ones include:

- 12X18H10T (AISI 321 equivalent): Ti-stabilized austenitic steel for corrosion and intergranular corrosion resistance.

- 08X18H10T (AISI 304Ti equivalent).

- 10X17H13M2T (AISI 316Ti equivalent) for enhanced chloride resistance.

- Trim (Stem, Gate, Seats): Grades like 20X13 (AISI 420), 14X17H2, or hard-faced equivalents.

- Design & Manufacturing Standards (GOST):

- GOST 9697 or GOST 5762: Core standards for steel gate valve design and technical specifications.

- GOST 9544: Standard for pressure and tightness tests (seat leakage rates).

- GOST 33257: For pipeline valves (aligned with API 6D principles).

- Connection Standards (GOST):

- GOST 12815 or the newer GOST 33259 (PN series): Define flange dimensions, pressure ratings (PN10, PN16, PN25, PN40, etc.), face types, and drilling patterns.

- Critical Note: GOST flange dimensions are NOT interchangeable with ASME B16.5 or EN 1092-1 flanges of the same nominal size.

How to Select Gost Stainless Steel Gate Valve

How to Purchase

Specify Requirements Precisely:

- State the need for a valve manufactured to GOST design standards with GOST stainless steel materials.

- Define: Size (DN), Pressure Rating (PN according to GOST), Fluid Media (concentration, temperature to select correct steel grade), and Operation Temperature.

- Specify the exact stainless steel grade per GOST 5632 (e.g., 12X18H10T).

- Mandatory Certification: Require GOST R Certificate of Conformity or the EAC TR CU 010/032 certification for the Customs Union market.

- Find Specialized Manufacturers: Source from suppliers with proven expertise in producing GOST-valves, particularly in stainless steel. Regions include Russia, Ukraine, and specialized manufacturers in China/India serving the CIS market.

- Request Detailed GOST Documentation: The quotation must include:

- Technical passport (data sheet) in Russian/English listing all GOST standards and material grades.

- Dimensional drawing according to GOST.

- Copy of the valid GOST R or EAC Certificate for the valve model.

- Material certificates from the steel mill in GOST format.

- Place Order with Clear Terms: The purchase order must be explicit: "Stainless Steel Gate Valve, DN80, PN16, Design per GOST 9697, Body/Bonnet Material 12X18H10T per GOST 5632, Flanges per GOST 12815-80, with full EAC Certification."

Pre-Shipment Inspection for Export Gost Stainless Steel Gate Valve and Key Considerations

Pre-Export Inspection and Precautions

Inspection Protocol:

- Documentation First: Scrutinize the GOST Material Certificates (must specify heat number, chemical composition, and mechanical properties per GOST 5632). Verify the EAC/GOST R Certificate is authentic and covers the exact valve type.

- Material Verification: Use a handheld XRF analyzer to confirm the chemical composition of the body and stem matches the specified GOST grade (e.g., presence of Ti in 12X18H10T).

- Dimensional & Marking Check: Verify all body markings (DN, PN, material grade "12X18H10T", GOST standard, manufacturer). Crucially, check flange dimensions with GOST-specific templates.

- Surface Finish Inspection: Check for defects, proper welding, and smooth machining. For sanitary applications, verify Ra surface roughness.

- Witness Pressure Testing per GOST 9544: Includes shell test (1.5x PN) and seat leakage test (1.1x PN). The acceptable leakage rate is defined by the standard's class (e.g., Class A for "no visible leakage").

- Special Test for Stainless Steel: For certain applications, a Intergranular Corrosion Test (per GOST 6032) may be required for austenitic steels. Review the certificate for this test if specified.

Precautions:

- Flange Incompatibility Warning: Reiterate and verify that the end user's pipeline flanges are also to GOST standards. Mismatch is a common and critical error.

- Passivation: Ensure the stainless steel surfaces have been properly passivated to enhance the corrosion-resistant oxide layer.

- Ship in Open Position: To protect the seats.

- Protect Sealing Surfaces: Use non-ferrous (e.g., plastic, aluminum) flange protectors to prevent iron contamination (embedding), which can cause rust spots on the stainless steel.

- Export Documentation: Ensure the Packing List and Commercial Invoice accurately describe the goods with GOST references. The EAC Certificate, GOST Test Reports, and Material Certificates must be original or certified copies, ideally translated, and placed in a waterproof pouch inside the crate.

- Crating: Use clean, dry wooden crates. Mark with "Stainless Steel - Handle with Care," "Do Not Use Steel Hooks Directly," and "Protect from Iron Contamination."

Gost Stainless Steel Gate Valve Main part materials and property

| Body Bonnet | Slem | Seat | Sealng shim | Pacing | Working emperatre |

Saitable miedium |

| 5L | 2013

F304 F316 |

130

STELITE F304 F316 |

304+Hedble

Graphite 316+Feible Grapite 08 Soft Steel |

Fesbe

Graphite PTFE |

-196℃

~565℃ |

Water

Seam OI Gs Nitieacid Acelc adid |

| 20G | ||||||

| L1 | ||||||

| CF8 | ||||||

| 12018NM | ||||||

| CF8M | ||||||

| 0018N1ZMozTi |

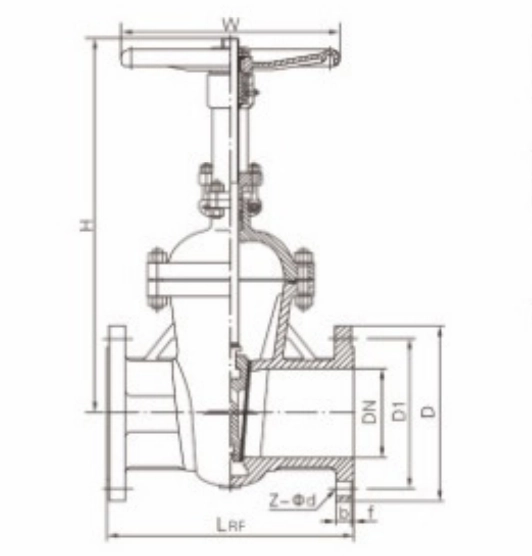

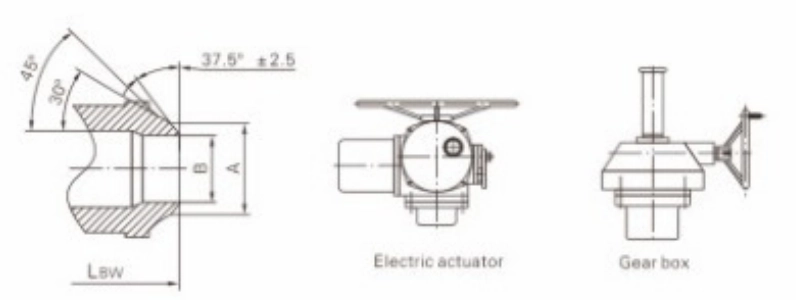

Gost Stainless Steel Gate ValveMain external and connection dimension (PN16)

| DN | LRF | LBw | D | Di | b | Z-φd | A | B | H | W |

| 50 | 180 | 180 | 160 | 125 | 16 | 4-φ18 | 60 | 52 | 355 | 200 |

| 65 | 190 | 190 | 180 | 145 | 20 | 4-φ18 | 75 | 63 | 376 | 200 |

| 80 | 210 | 210 | 195 | 160 | 20 | 8-φ18 | 91 | 78 | 435 | 280 |

| 100 | 230 | 230 | 215 | 180 | 20 | 8-φ18 | 117 | 102 | 502 | 300 |

| 125 | 255 | 255 | 245 | 210 | 22 | 8-Φ18 | 144 | 128 | 615 | 320 |

| 150 | 280 | 280 | 280 | 240 | 22 | 8-φ22 | 172 | 154 | 675 | 360 |

| 200 | 330 | 330 | 335 | 295 | 24 | 12-φ22 | 223 | 203 | 820 | 400 |

| 250 | 450 | 450 | 405 | 355 | 26 | 12-φ26 | 278 | 255 | 970 | 450 |

| 300 | 500 | 500 | 460 | 410 | 28 | 12-φ26 | 329 | 305 | 1145 | 500 |

| 350 | 550 | 550 | 520 | 470 | 30 | 16-φ26 | 362 | 337 | 1280 | 550 |

| 400 | 600 | 600 | 580 | 525 | 32 | 16-φ30 | 413 | 387 | 1451 | 600 |

| 450 | 650 | 650 | 640 | 585 | 40 | 20-φ30 | 464 | 438 | 1545 | 650 |

| 500 | 700 | 700 | 710 | 650 | 44 | 20-φ33 | 516 | 489 | 1678 | 700 |

| 600 | 800 | 800 | 840 | 710 | 54 | 20-φ36 | 619 | 591 | 1875 | 800 |

| 700 | 900 | 900 | 910 | 840 | 40 | 24-φ36 | 721 | 695 | 2085 | 900 |

| 800 | 1000 | 1000 | 1020 | 950 | 42 | 24-φ39 | 825 | 797 | 2405 | 950 |

| 900 | 1100 | 1100 | 1125 | 1050 | 44 | 28-φ39 | 927 | 899 | 2950 | 1000 |

| 1000 | 1242 | 1242 | 1255 | 1170 | 46 | 28-φ42 | 一 | 3244 | 1000 |

Gost Stainless Steel Gate Valve Main external and connection dimension (PN25)

| DN | L | D | D1 | b | Z-φd | A | B | H | W |

| 50 | 250 | 160 | 125 | 20 | 4-φ18 | 60 | 52 | 355 | 200 |

| 65 | 265 | 180 | 145 | 22 | 8-φ18 | 75 | 63 | 376 | 200 |

| 80 | 280 | 195 | 160 | 24 | 8-φ18 | 91 | 78 | 435 | 280 |

| 100 | 300 | 230 | 190 | 24 | 8-φ22 | 117 | 102 | 502 | 300 |

| 125 | 325 | 270 | 220 | 26 | 8-φ26 | 144 | 128 | 615 | 320 |

| 150 | 350 | 300 | 250 | 30 | 8-φ26 | 172 | 154 | 675 | 360 |

| 200 | 400 | 360 | 310 | 34 | 12-φ26 | 223 | 203 | 820 | 400 |

| 250 | 450 | 425 | 370 | 36 | 12-φ30 | 278 | 255 | 970 | 450 |

| 300 | 500 | 485 | 430 | 36 | 16-φ30 | 329 | 305 | 1145 | 500 |

| 350 | 550 | 550 | 490 | 38 | 16-φ33 | 362 | 337 | 1280 | 550 |

| 400 | 600 | 610 | 550 | 40 | 16-φ36 | 413 | 387 | 1451 | 600 |

| 450 | 650 | 670 | 600 | 46 | 20-φ36 | 464 | 438 | 1545 | 650 |

| 500 | 700 | 730 | 660 | 48 | 20-φ36 | 516 | 489 | 1678 | 700 |

| 600 | 800 | 840 | 770 | 58 | 20-φ39 | 619 | 591 | 1875 | 800 |

| 700 | 900 | 960 | 875 | 50 | 24-φ42 | 721 | 695 | 2085 | 900 |

| 800 | 100 | 1085 | 990 | 54 | 24-φ48 | 825 | 797 | 2405 | 950 |

| 900 | 1100 | 1185 | 1090 | 58 | 28-φ48 | 927 | 899 | 2950 | 1000 |

| 1000 | 1242 | 1320 | 1210 | 62 | 28-φ55 | - | - | 3244 | 1000 |

We also supply fire valve and water valves.

.png)

.png)