Gost WCB Gate Valve

Gost WCB Gate Valve Definition and Components

What is a GOST WCB Gate Valve and its main parts?

A GOST WCB Gate Valve is a valve designed and manufactured to meet the standards of the GOST system (primarily the Russian Federation and CIS countries), while using ASTM A216 Grade WCB as the material for its primary pressure-containing parts (body and bonnet). This combination specifies a valve that meets post-Soviet design, testing, and documentation requirements but is made from a widely recognized international carbon steel casting material suitable for moderate temperatures and pressures.

Main Parts:

- Body & Bonnet: The main pressure-retaining components, typically made from ASTM A216 WCB (Carbon Steel). The bonnet may be bolted, welded, or pressure-sealed.

- Gate/Wedge: The sliding disc that shuts off the flow. It can be solid, flexible, or split.

- Stem: A rising stem (OS&Y - Outside Screw & Yoke) or non-rising stem. Transmits force from the handwheel to the gate.

- Seat Rings: The surfaces against which the gate seals. They can be integral (welded/threaded into the body) or separable (seat rings).

- Yoke & Yoke Bush/Nut: The assembly that houses the stem threads and connects the bonnet to the actuation mechanism.

- Handwheel or Gear Operator: Manual operation device.

- Packing Box: Contains stem packing (e.g., graphite) and a gland follower to create a seal around the stem.

- Flanges: Connection ends conforming to GOST flange standards (e.g., GOST 12815, GOST 33259).

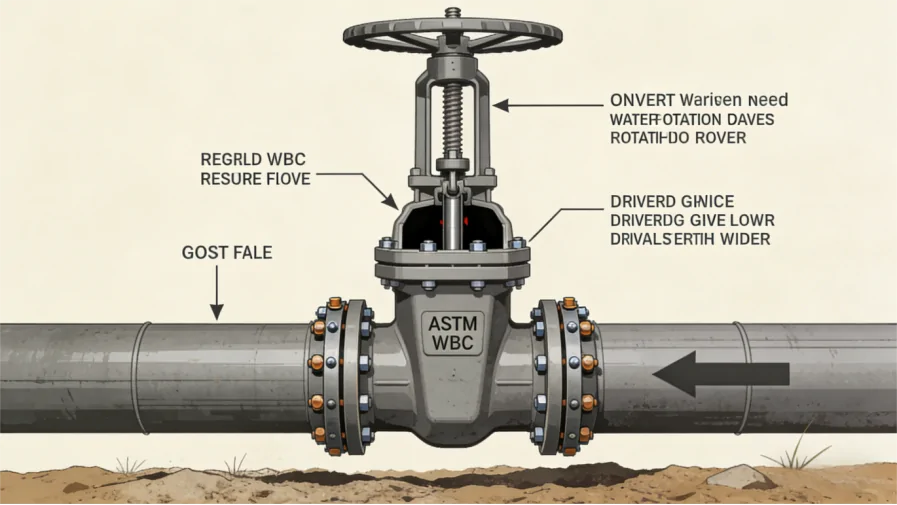

Role, Characteristics, and Application Scenarios of Gost WCB Gate Valve in Pipelines

Functions, Operational Features, Usage Scenarios, and Scenario Diagram

Functions: Primarily used for full on/off isolation in pipelines. It provides a tight seal when fully closed and minimal flow restriction when fully open.

Operational Features:

- Linear Motion: The gate moves perpendicular to the flow.

- Full Port Design: The bore diameter typically matches the pipeline ID, resulting in very low pressure loss when open.

- Slow Operation: Requires multiple turns of the handwheel, making it unsuitable for quick shut-off.

- Not for Throttling: Operating in a partially open position can cause vibration and erosion of the gate and seats.

- Usage Scenarios: Common in industrial applications within CIS regions and export projects to these areas.

- Oil & Gas Transmission: Onshore pipeline sections.

- Power Generation: Water and steam lines (within WCB temperature limits).

- Chemical & Petrochemical Plants: For non-corrosive services (oil, water, steam).

Water Supply & Distribution Networks.

Gost WCB Gate Valve Standards: Materials, Design, and Connections

Material, Design, and Connection Standards

This valve is defined by a hybrid of standards:

Industrial valves Material Standards:

- Primary Material: ASTM A216 Grade WCB for body and bonnet. Equivalent Russian grades might be referenced (e.g., 25Л, 20ХМЛ), but WCB is the international specification.

- Trim Materials: Stem (410 SS/13Х17Н2), seat rings (13Х17Н2 with Stellite overlay), packing (graphite).

- Design & Manufacturing Standards: GOST standards govern design, dimensions, and acceptance.

- GOST 9697 or GOST 5762: Core standards for steel gate valve design and technical conditions.

- GOST 9544: Standard for pressure testing of valve seats (leakage rates).

- GOST 33257 (API 6D analogues): For pipeline valves.

- Connection Standards: The flanges adhere to GOST standards, which differ from ASME/DIN.

- GOST 12815 or the newer GOST 33259 (PN series): Define flange face types (e.g., Type 1 - raised face), pressure ratings (PN10, PN16, PN25, PN40), drilling patterns, and dimensions.

- Crucial Note: GOST flange dimensions (bolt hole circle, diameter) are NOT interchangeable with ASME B16.5 or EN 1092-1 flanges of the same nominal size and pressure class

How to Select WCB Gate Valve

How to Purchase

Specify the Hybrid Requirements Clearly:

- State the need for a valve manufactured to GOST design standards (e.g., GOST 9697) but with ASTM A216 WCB material.

- Define: Size (DN), Pressure Rating (PN according to GOST), Temperature range, Fluid Media.

- Specify connection standard (e.g., Flange to GOST 12815-80 PN16).

- Clarify required certifications: GOST R Certificate of Conformity (or newer EAC TR CU 010/032 certification for Customs Union markets) is often mandatory for import.

- Find Specialized Manufacturers/Exporters: Target suppliers in countries with a history of GOST-standard manufacturing (Russia, Ukraine, China, India specializing in CIS exports). Verify they have an active quality system and can provide the necessary CIS market certifications.

- Request Detailed Documentation in Offer: Require a technical data sheet that explicitly lists both the GOST standards and the ASTM material spec. Ask for:

- Dimensional drawing according to GOST.

- Material list with ASTM and equivalent GOST grades.

- Copies of valid GOST R or EAC Certificates.

- Proposed test protocol (according to GOST 9544).

- Order with Precise Contractual Terms: The purchase order must be unambiguous: "Gate Valve, DN100, PN16, GOST 12815 flanges, Design per GOST 9697, Body/Bonnet Material ASTM A216 WCB, with full GOST certification." Include Incoterms suitable for export from the supplier's country.

Pre-Shipment Inspection for Export WCB Gate Valve and Key Considerations

Pre-Export Inspection and Precautions

Inspection Protocol:

- Documentation Review First: Scrutinize the Material Certificates (must show ASTM A216 WCB heat numbers) and the GOST/EAC Certificate of Conformity for authenticity.

- Dimensional & Marking Check: Verify all markings on the valve body (DN, PN, material grade, manufacturer, GOST standard). Crucially, check flange dimensions (outer diameter, bolt hole count, bolt circle diameter) with GOST gauge templates.

- Material Verification: A handheld XRF analyzer can be used to spot-check chemical composition against WCB specifications.

- Witness Pressure Testing: Testing must follow GOST 9544. This typically includes:

- Shell Test: 1.5x PN.

- Seat Leakage Test: 1.1x PN. The permissible leakage rate is defined by the GOST standard and class (usually "A" class for zero visible leakage).

- Functional Test: Operate the valve fully open to closed, checking for smooth operation, proper alignment, and no excessive friction.

- Packaging & Preservation: Check for proper rust prevention (varnish/grease on machined surfaces). Flange faces and welding bevels must have sturdy protectors.

Precautions:

- Flange Compatibility Warning: The biggest risk is assuming GOST flanges match ASME/DIN. They do not. Confirm the mating flanges in the destination pipeline are also to GOST standards.

- Ship in Open Position: The valve should be shipped slightly open to relieve seat load.

- Secure Internals: For rising stem valves, ensure the stem is secured to prevent it from turning during transit.

- Export Documentation: The Packing List, Commercial Invoice, and Certificate of Origin must be accurate. The GOST/EAC Certificate and Test Reports must be originals or certified copies, translated if required, and placed in a waterproof pouch inside the shipping crate.

- Crating: Use robust timber crates. Mark clearly with lifting points, center of gravity, and "Protect Flange Faces."

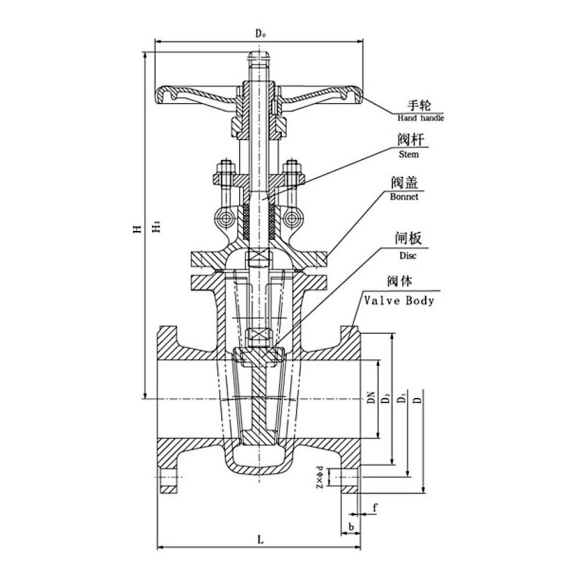

WCB Gate Valve Outline and connecting measurement

| Type | Nominal (mm) |

Measurement(mm) | Reference Weight (kg) | ||||||||

| L | D | D1 | D2 | b-f | Zx фd | H | H1 | D0 | |||

| Z41H-16C | 50 | 180 | 160 | 125 | 102 | 16-3 | 4× ф 18 | 288 | 341 | 180 | 14.61 |

| 80 | 210 | 195 | 160 | 133 | 18-3 | 4× ф 18 | 343 | 426 | 215 | 24 | |

| 100 | 230 | 215 | 180 | 158 | 20-3 | 8× ф 18 | 392 | 486 | 245 | 33.9 | |

| 150 | 280 | 280 | 240 | 212 | 24-3 | 8× 22 | 559.5 | 704 | 275 | 67.03 | |

| 200 | 330 | 330 | 295 | 268 | 26-3 | 12× 22 | 696 | 896 | 320 | 107.8 | |

We also supply fire valve and water valves.

.png)

.png)