Heavy Hammer Type Hydraulic Control System HHD743

Heavy Hammer Type Hydraulic Control System HHD743 Definition and Components

What is the HHD743 and its Main Parts?

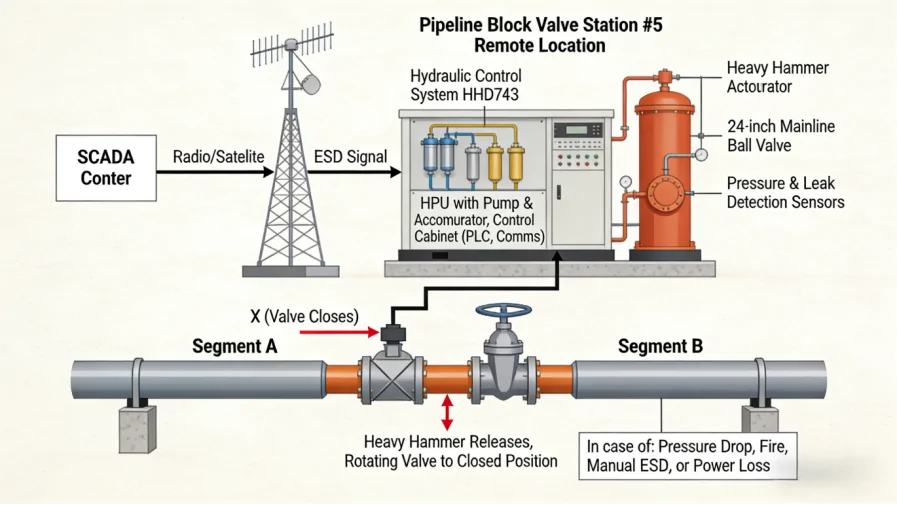

The HHD743 Heavy Hammer Type Hydraulic Control System is a fail-safe actuator for pipeline valves (typically mainline block valves or emergency shutdown valves). It uses a stored mechanical energy system (the "heavy hammer") to close the valve automatically upon loss of hydraulic pressure or upon a command signal.

Hydraulic System Control Valve Main Components:

- Hydraulic Power Unit (HPU): The core, containing an electric or pneumatic motor, hydraulic pump, reservoir, filters, and accumulators. It generates and stores pressurized hydraulic fluid.

- Heavy Hammer Actuator: The namesake component. A large, weighted mass (the hammer) is held in a cocked position by hydraulic pressure. Upon release, it falls or swings, converting potential energy into kinetic energy to rotate the valve stem.

- Solenoid Control Valve (Pilot Valve): An electrically operated valve that controls the flow of hydraulic fluid to the actuator. It triggers the hammer release upon an electrical signal from the control system.

- Manual Release Mechanism: A backup system (lever or button) to mechanically trip the hammer manually for local emergency closure or maintenance.

- Hydraulic Control Panel: Includes gauges, pressure switches, local controls, and piping to monitor and manage system pressure.

- Accumulators: Nitrogen-charged bottles that store hydraulic energy to allow multiple valve cycles even if the main pump fails.

- Control Cabinet: Houses the electrical controls, PLC/SCADA interface, battery backup, and instrumentation for remote monitoring and control.

Role, Characteristics, and Application Scenarios of Heavy Hammer Type Hydraulic Control System HHD743 in Pipelines

Functions, Operational Features, and Usage Scenarios

- Water Valves Functions in Pipelines:

- Emergency Shutdown (ESD): Automatically isolates a pipeline section in case of a leak, rupture, fire, or overpressure detected by the pipeline SCADA system.

- Sectionalizing: Allows for isolation of a specific segment for maintenance or repair, minimizing product loss and downtime.

- Fail-Safe Closure: Ensures valve closure upon loss of hydraulic pressure, electrical power, or control signal (a critical safety feature).

Operational Features:

- High Reliability: Mechanical/hydraulic operation ensures function even with total power loss.

- Rapid Closure: The heavy hammer provides fast, positive torque for quick valve shut-off.

- Dual-Phase Operation: Can be reset and opened hydraulically (using the HPU pump) after a trip event.

- Remote & Local Control: Integrates with SCADA for remote operation but has local manual override.

Typical Usage Scenarios:

- Pipeline Pump Stations: Upstream and downstream of mainline pumps.

- Pipeline Crossings: At major river, road, or railway crossings.

- Storage Terminal Inlets/Outlets: To isolate terminals from the pipeline.

- High-Consequence Areas (HCAs): Near environmentally sensitive or populated zones.

- Block Valve Stations: Along the pipeline at regular intervals as per regulatory requirements.

Heavy Hammer Type Hydraulic Control System HHD743 Standards: Materials, Design, and Connections

Material, Design, and Connection Standards

These systems are built to stringent international standards to ensure reliability and safety.

Control Valve for Water Material Standards:

- Actuator/Housing: Carbon steel (ASTM A216 WCB) or low-temperature steel for cold climates. Internal components are often stainless steel (ASTM A479) for corrosion resistance.

- Hydraulic Tubing/Piping: ASTM A106/ASME SA106 seamless steel pipe.

- Seals & O-Rings: Nitrile (Buna-N), Viton, or HNBR suitable for petroleum-based hydraulic fluids and environmental conditions.

Design & Manufacturing Standards:

- Pressure Vessels (Accumulators): ASME Boiler and Pressure Vessel Code, Section VIII.

- General Valve Actuator: API 6D / ISO 14313 (Pipeline Valves), API 6FA (Fire Test).

- Hydraulic Systems: ISO 4413 (Hydraulic Fluid Power) and NFPA/T2.13.1.

- Electrical Enclosures: NEMA 4X / IP66 (weatherproof, corrosion-resistant) for outdoor installation.

- Safety & Functional Safety: IEC 61508 / IEC 61511 (SIL rated for ESD functions).

Connection Standards:

- Valve Interface: ISO 5211 mounting pad is standard for connecting the actuator to the valve.

- Hydraulic Connections: SAE J514 (JIC 37°) flare fittings or ISO 8434 (Metric) are common. Tube fittings follow SAE J1453.

- Electrical Connections: Conduit entries via NPT or Metric threads; terminal blocks per IEC/UL standards

How to Select Heavy Hammer Type Hydraulic Control System HHD743

Procurement Process

Purchasing an HHD743 system requires technical diligence:

Define Specifications:

Valve type, size, torque/required thrust, operating pressure.

Required closing/opening time.

Environmental conditions (temperature, climate, hazardous area classification - e.g., ATEX, IECEx Zone).

Communication protocols (Modbus, DNP3, IEC 60870-5, etc.).

Required Safety Integrity Level (SIL) certification.

Identify Reputable Suppliers:

Look for established manufacturers of pipeline actuators (e.g., Emerson, Rotork, Limitorque, or specialized hydraulic systems integrators).

Verify their project history in oil & gas pipelines.

Technical Bid Evaluation:

Require detailed datasheets, P&IDs, and control schematics.

Ensure proposed materials and standards meet your project's regulations.

Evaluate the offered HPU capacity, accumulator volume, and backup power.

Commercial & Logistics Terms:

Clarify delivery lead time (often 12-20 weeks for custom systems)

Incoterms (FCA, FOB, CIF, etc.) and packaging for overseas shipment.

Scope of supply: Does it include hydraulic fluid, commissioning spares, on-site supervision?

After-Sales Support:Warranty terms (typically 12-18 months).

Availability of operation & maintenance manuals, training, and local service support.

Pre-Shipment Inspection for Export Heavy Hammer Type Hydraulic Control System HHD743 and Key Considerations

Pre-Shipment Inspection & Export Precautions

A thorough Factory Acceptance Test (FAT) is critical before shipment.

Inspection Checklist:

- Documentation Review: Verify manuals, test certificates (material, welding, NDT), hydraulic fluid analysis report, and drawings are complete and correct.

- Visual & Dimensional Check: Confirm no damage, proper paint (often epoxy coating), correct labeling, and interface dimensions (ISO 5211).

Functional FAT:

- Leak Test: Hydraulic system held at maximum operating pressure (e.g., 1.5x) with no visible leaks.

- Trip Test: Actuate the system via electrical signal and manual release. Measure and record closure time. Verify hammer release and reset action is smooth.

- Control System Test: Verify PLC logic, alarm functions (low pressure, low temperature), and communication with a simulated SCADA master.

- Loss-of-Power Test: Simulate power failure; the system should trip as designed.

- Pressure Switch & Safety Device Calibration: Verify set points.

Key Precautions for Export:

- Preservation & Packaging: The system must be fully dehydrated and filled with preservation oil in the hydraulic circuit to prevent internal corrosion during transit. All openings should be sealed with caps.

- Robust Crating: Use a weatherproof, rigid wooden crate on a skid. The heavy hammer must be mechanically locked or secured to prevent accidental release during transport. Internal components should be blocked and braced.

- Environmental Protection: Include desiccant bags (silica gel) inside the control cabinet and hydraulic enclosures. Use VCI (Vapor Corrosion Inhibitor) paper or coatings.

- Shipping Marks: Clearly mark "Heavy Lift," "Top," "Keep Dry," and include project name, item number, and lifting points.

- Accompanied Documentation: Pack a duplicate set of FAT reports, packing lists, and preservation certificates in a waterproof envelope attached to the crate. The original should ship separately with commercial documents.

Heavy Hammer Type Hydraulic Control System HHD743 Chart

| Technical standards | Open-close parameters | Main information | |||

| Design | GB/T14478 | Open | 5-120S(adjustable) | Size | DN500-DN3200 |

| Hydraulic system | JB/T5299 | Quick close | 2-30S(adjustable) | Body | Ductile iron |

| Connection | GB/T9113 | Slow close | 5-120S(adjustable) | Sisc | Ductile iron |

| Face to face | GB/T12221 | Quick close angle | 70+10°(adjustable) | Stem | 2Cr13 |

| Test & inspection | GB/T13927 | Slow close angle | 20+10°(adjustable) | Seat | 1Cr18Ni9Ti |

Note:1. Other specifications and flange standards are available upon request.

- Design and specifications are subject to change without prior notice.

.png)

.png)