How to Clean a Y Strainer Screen: A Practical Guide for Reliable Pipeline Operation

December 18, 2025

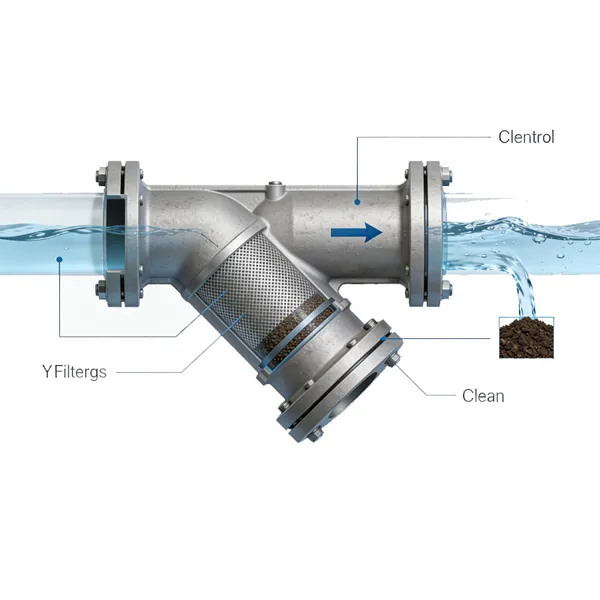

In water supply, HVAC, fire protection, and industrial piping systems, Y strainer valve play a simple but critical role. They protect pumps, valves, meters, and other downstream equipment by removing debris from the fluid. However, even the best Y strainer will fail to perform if the screen is not cleaned regularly.

Many system issues—pressure drop, reduced flow, or equipment damage—can be traced back to a clogged Y strainer. Knowing how to clean the strainer screen correctly is essential for maintaining system efficiency and extending equipment life.

This guide from Fuid Tech Group explains when and how to clean a Y strainer, what tools are required, and how proper maintenance improves long-term performance.

What Is a Y Strainer and Why Cleaning Matters

A Y type strainer valve is a mechanical filtration device installed in a pipeline. Its Y-shaped body houses a removable screen that captures solids such as rust, sand, scale, and debris.

Common Applications of Y Strainers

- Water supply systems

- Fire protection pipelines

- HVAC and cooling systems

- Industrial process lines

Over time, trapped debris accumulates on the screen. If cleaning is delayed, several problems may occur:

- Increased pressure loss

- Reduced flow rate

- Pump cavitation

- Valve or equipment damage

Regular cleaning keeps the strainer working as designed and prevents unnecessary downtime.

| Standard Category | Applicable Standards | Specific Requirements |

|---|---|---|

| Design Standard | ASME B16.34 (US) | Pressure-temperature ratings, design requirements |

| BS EN 12516 (EU) | ||

| GB/T 14382 (China) | ||

| Material Standards | ASTM A216 (WCB) | Body and component materials |

| ASTM A351 (CF8/CF8M) | ||

| ASTM B62 (Bronze) | ||

| DIN 1.4401/1.4408 | ||

| Connection Standards | ASME B16.5 (Flanges) | End connection specifications |

| ASME B1.20.1 (NPT Threads) | ||

| BS EN 1092 (Flanges) | ||

| DIN 2999 (Threads) | ||

| Screening Standards | ISO 2194 (Wire Cloth) | Screen opening specifications |

| ASTM E11 (Test Sieves) | ||

| Mesh size standards | ||

| Testing Standards | API 598 | Pressure testing procedures |

| ISO 5208 | ||

| MSS SP-61 |

When Should You Clean a Y Strainer Screen?

Cleaning frequency depends on the working conditions. There is no single schedule that fits every system.

Typical Signs That Cleaning Is Needed

- Noticeable pressure drop across the strainer

- Reduced downstream flow

- Abnormal noise from pumps

- Irregular system performance

In new installations, debris levels are usually higher. The first cleaning should happen shortly after commissioning. After that, operators can adjust the schedule based on actual conditions.

For systems with poor water quality or heavy particulate content, more frequent inspection and cleaning is necessary.

Step-by-Step Guide: How to Clean a Y Strainer Screen

Cleaning a Y strainer is straightforward, but correct steps ensure safety and avoid damage.

Step 1: Isolate and Depressurize the System

Before starting:

- Shut off upstream and downstream valves

- Release internal pressure

- Allow the pipeline to cool if handling hot media

Never attempt to open a pressurized strainer.

Step 2: Open the Strainer Cap or Cover

Most Y strainers feature:

- A threaded cap

- A bolted cover

Use appropriate tools to loosen the cap slowly. Keep a container ready to catch any remaining fluid.

Step 3: Remove the Screen Carefully

Pull out the strainer screen by hand or with light tools.

Avoid bending or deforming the mesh, especially for fine screens.

Inspect the screen for:

- Debris buildup

- Corrosion

- Damage or deformation

If the screen shows severe wear, replacement is recommended.

Step 4: Clean the Screen Thoroughly

Cleaning methods depend on the type of debris.

- Water rinsing

Suitable for sand, rust, and loose particles. - Soft brush cleaning

Helps remove stubborn deposits without damaging the mesh. - Mild detergent or solvent

Used for oil or grease contamination. Ensure compatibility with the screen material.

Avoid aggressive chemicals that may weaken stainless steel or other materials.

Step 5: Inspect Seals and Reinstall the Screen

Before reassembly:

- Check the gasket or O-ring

- Replace worn or damaged seals

Reinsert the clean screen, tighten the cap or bolts evenly, and ensure proper alignment.

Step 6: Restart the System and Check for Leaks

Slowly reopen the valves and allow the system to pressurize gradually.

Observe the strainer area for leaks and confirm normal pressure and flow.

Common Mistakes to Avoid During Cleaning

Even simple maintenance tasks can cause issues if done incorrectly.

Using Excessive Force

Overtightening the cap or bolts may damage threads or seals. Always follow recommended torque values.

Ignoring Screen Damage

A torn or deformed screen reduces filtration efficiency. Cleaning cannot fix structural damage.

Skipping Regular Inspection

Waiting until flow problems appear increases system risk. Preventive maintenance is always more efficient.

How Proper Cleaning Extends System Life

Regular Y strainer maintenance offers several long-term benefits:

- Protects pumps and control valves

- Reduces maintenance costs

- Improves system stability

- Extends service life of downstream equipment

In fire protection systems, clean strainers also help ensure reliable water delivery during emergencies, where performance cannot be compromised.

Y Strainers from Fuid Tech Group: Designed for Easy Maintenance

As a professional pipe fitting and valve supplier, Fuid Tech Group designs Y strainers with practical operation in mind.

Our Y strainers feature:

- Durable ductile iron, carbon steel, or stainless steel bodies

- Precision stainless steel screens

- User-friendly caps and covers for easy cleaning

- Stable performance in water, HVAC, and fire systems

We provide complete technical specifications and support to help customers choose the right strainer for their application.

.png)

.png)