Manual Wafer Butterfly Valve D371X

Manual Wafer Butterfly Valve D371X Purpose

This Wafer Style Butterfly Valve is used as a cutoff and adjusting equipment for the various water supply and drainage pipelines in building chemical, medicine, textile, ship and other industries.

Manual Wafer Butterfly Valve D371X Definition and Components

A Manual Wafer Butterfly Valve Model D371X is a quarter-turn, lug-less wafer-style isolation valve designed for installation between two pipeline flanges. The "D371X" model code is significant: "D" typically denotes a butterfly valve, "3" signifies a gear-operated manual actuator, "71" indicates a wafer body design, and "X" represents a resilient EPDM seat. This fire protection valves is engineered for applications requiring higher operating torque than a simple lever handle can provide, offering better mechanical advantage and control.

Water Supply Valves Main Parts:

- Wafer Body: The central, disc-shaped housing (typically ductile iron) that fits between pipeline flanges. It has bolt holes for the flange studs to pass through.

- Disc (Butterfly): The circular plate (often stainless steel or ductile iron coated) that rotates to control flow.

- Stem (Shaft): A robust stainless steel shaft connecting the disc to the gearbox.

- Resilient Seat (EPDM): An elastomer ring (Ethylene Propylene Diene Monomer) that provides a tight seal against the disc.

- Manual Gear Operator (Worm Gear Actuator): The key feature. Consists of a handwheel that turns a worm gear, which rotates the valve stem. This provides high torque multiplication for easier operation of larger valves or valves under higher pressure.

- Position Indicator: Shows the degree of disc opening (e.g., 0°, 45°, 90°).

- Stem Seals & Bushings: Prevent leakage and support smooth rotation.

Role, Characteristics, and Application Scenarios of Manual Wafer Butterfly Valve D371X in Pipelines

Functions in Pipelines:

- Isolation/Shut-off: Primary function for stopping flow in a pipeline.

- Throttling/Regulation: The gear operator allows for precise intermediate positioning to regulate flow or pressure.

- Bidirectional Blocking: Effective sealing against pressure from either flow direction.

- Operational Features:

- High-Torque Operation: The gearbox reduces the effort required to operate the valve, making it suitable for larger sizes (typically DN150 / 6" and above) and higher differential pressures.

- Precise Flow Control: The multi-turn handwheel allows fine adjustment of the disc position.

- Compact Wafer Design: Saves space and weight compared to gate valves; does not require its own flange bolts.

- Durable for Frequent Operation: Gear mechanism is more robust for regular use than a simple lever.

- Locking Capability: Most gear operators have a provision for padlocking the valve in a desired position.

Common Usage Scenarios:

- Water Supply & Distribution Mains: For isolating sections of the network.

- Wastewater Treatment Plants: On pump discharge, aeration lines, and sludge lines.

- HVAC Systems: In large chilled water or heating water circuits.

- Industrial Process Lines: For water, compressed air, and other non-aggressive media.

- Power Plant Cooling Water Systems.

- Irrigation Canals and Pump Stations.

Manual Wafer Butterfly Valve D371X Standards: Materials, Design, and Connections

Material Standards:

- Body: Ductile Iron (ASTM A536) with epoxy powder coating (standard). Alternative: Carbon Steel (ASTM A216 WCB) or Stainless Steel (ASTM A351 CF8/CF8M).

- Disc: Ductile Iron with Ni-plating or Stainless Steel (ASTM A351 CF8/CF8M).

- Stem: Stainless Steel (AISI 431, 304, or 316).

- Seat: EPDM (for water, -20°C to 120°C), NBR, or Viton for chemical service.

- Gearbox Housing: Cast Iron or Aluminum Alloy.

Design & Performance Standards:

- API 609: The primary standard for "Butterfly Valves: Double Flanged, Lug- and Wafer-Type."

- ISO 5752: Standard for face-to-face dimensions.

- ISO 5211: Standard for mounting dimensions of gear operators (ensuring actuator interchangeability).

- Pressure Rating: Commonly PN10/PN16 (Class 150). Available up to PN25 (Class 150 for certain sizes).

- Leakage: Seat leakage typically meets ISO 5208 Rate A (bubble-tight) or Rate B.

Connection Standards:

- Wafer Design: Conforms to ANSI B16.10 face-to-face dimensions. Fits between standard ANSI B16.1 (Cast Iron) or B16.5 (Steel) flanges.

- Flange Compatibility: Designed for Raised Face (RF) or Flat Face (FF) flanges of the corresponding pressure class.

How to Select Such Manual Wafer Butterfly Valve D371X

Define Application Specifications:

- Fluid, Temperature, Pressure: Confirm media compatibility, max temperature (<120°C for EPDM), and required Pressure Nominal (PN) rating.

- Size: Exact nominal diameter (e.g., DN200 / 8").

- Material Specification: Standard is Epoxy-Coated Ductile Iron body, Stainless Steel disc/stem, EPDM seat. Request full material breakdown.

- Gearbox Specification: Required input torque (based on valve size/pressure), number of turns from open to closed, and handwheel type (e.g., with locking plate).

Specify Quality & Compliance Requirements:

- Standards: Explicitly state conformance to API 609.

- Testing & Documentation: Require a factory test certificate per API 598 (shell test & seat test). Request Material Test Reports (MTRs) for body, disc, and stem.

- Interchangeability: Ensure the gear operator complies with ISO 5211 mounting pad specifications.

Supplier Selection & Ordering:

- Source from reputable industrial valve manufacturers or authorized distributors.

- Provide a detailed inquiry data sheet. For bulk orders, request a production sample for pre-shipment approval.

- Compare Total Cost of Ownership, considering warranty, availability of spare parts (like seals, gear sets), and technical support.

Pre-Shipment Inspection for Export Manual Wafer Butterfly Valve D371X and Key Considerations

Visual & Dimensional Inspection:

- Check for damage to coating, gearbox, and handwheel.

- Verify nameplate data (Size, PN, Model, Materials) matches the purchase order.

- Measure face-to-face dimensions against ISO 5752.

- Ensure the disc rotates freely without binding by operating the handwheel through its full range. The position indicator should move correspondingly.

Review of Mandatory Documentation:

- Factory Test Certificate (API 598): This is non-negotiable. It must certify successful hydrostatic shell test (at 1.5x PN) and seat leakage test (at 1.1x PN).

- Material Certificates: Review MTRs for critical components.

- Packing List: Verify item count and description.

Butterfly Valve for Water Packaging Inspection:

- The valve must be dry and clean internally. The disc should be in a partially open position (approx. 5°) to relieve seat stress during transport.

- All machined faces and sealing surfaces must be protected by taped-on cardboard or plastic covers, not loose caps.

- The gear operator should be protected from impact. The handwheel must be secured to prevent rotation during transit.

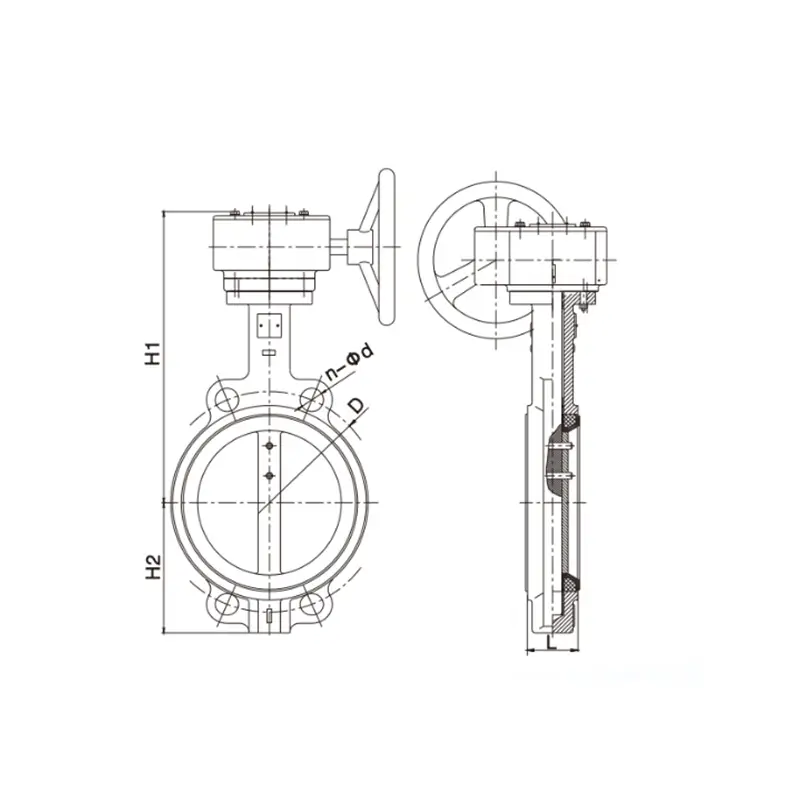

Manual Wafer Butterfly Valve D371X Main Dimensions(mm)

|

DN |

40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

| L | 33 | 43 | 46 | 46 | 52 | 56 | 56 | 60 | 68 | 78 |

| D | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 355 | 410 |

| n-Фd | 4-19 | 4-19 | 4-19 | 8-19 | 8-19 | 8-19 | 8-23 | 12-23 | 12-28 | 12-28 |

| H1 | 180 | 182 | 194 | 200 | 227 | 238 | 260 | 304 | 340 | 389 |

| H2 | 73 | 75 | 85 | 92 | 109 | 130 | 139 | 173 | 207 | 235 |

Note:1. Other specifications and flange standards are available upon request.

- Design and specifications are subject to change without prior notice.

.png)

.png)