Pressure Switch

Pressure Switch Definition and Components

Pressure Switch is an electro-mechanical device that monitors fluid pressure and opens or closes electrical contacts when a pre-set pressure threshold is reached. It converts pressure changes into electrical signals for control and alarm functions.

Pressure Valve Switch Main Components:

Pressure Sensing Element

- Diaphragm: Flexible membrane that flexes with pressure changes

- Piston: Solid piston that moves with pressure (for higher pressures)

- Bellows: Corrugated metal tube that expands/contracts

- Bourdon Tube: C-shaped tube that straightens with pressure

Switch Mechanism

- Electrical Contacts: SPDT (Single Pole Double Throw) or DPDT contacts

- Contact Block: Insulated housing for electrical connections

- Terminals: Screw terminals for wiring connections

Adjustment System

- Set Point Adjustment: Spring tension or screw mechanism

- Differential Adjustment: Adjusts pressure difference between on/off points

- Calibration Scale: Markings for pressure settings

Housing & Connections

- Enclosure: Weatherproof or explosion-proof housing

- Pressure Port: ¼" NPT or other connection to pipeline

- Conduit Connection: For electrical wiring protection

- Diaphragm Seal: Optional for corrosive fluids

Role, Characteristics, and Application Scenarios of Pressure Switch in Pipelines

Primary Functions:

- Pressure Monitoring: Continuously measures system pressure

- Alarm Activation: Triggers alarms at high or low pressure limits

- Equipment Control: Starts/stops pumps, compressors, or valves

- System Protection: Prevents overpressure or vacuum conditions

- Process Control: Maintains pressure within operating ranges

Fire Valve Operational Features:

- Adjustable Set Points: Field-adjustable trip pressures

- Wide Pressure Ranges: From vacuum to 10,000+ PSI

- Multiple Contact Arrangements: SPDT, DPDT, NO, NC configurations

- Hysteresis/Differential: Adjustable difference between on/off points

- Visual Indicators: Often include status flags or windows

Application Scenarios:

- Fire Protection Systems: Alarm valve monitoring, pump control

- Industrial Processes: Compressor control, boiler safety

- HVAC Systems: Chilled water, heating system pressure control

- Water Treatment: Pump control, filter monitoring

- Manufacturing: Hydraulic system protection, pneumatic control

Pressure Switch Standards: Materials, Design, and Connections

Material Standards:

- Pressure Chamber: Brass (ASTM B584), Stainless Steel 304/316, Monel

- Diaphragm/Seals: EPDM, Viton, Buna-N, PTFE, Neoprene

- Electrical Contacts: Silver, gold-plated, or tungsten

- Housing: Aluminum, steel, or plastic (UL94 rated)

- Springs: Stainless steel 302/316

Design Standards:

- UL 353: Standard for Pressure Switches

- FM 1320: Approval Standard for Waterflow Alarm Devices

- EN 14597: Temperature and pressure control devices

- CSA 22.2: Canadian safety standard

- ATEX/IECEx: For explosive atmospheres

Connection Standards:

- Pressure Port: ¼" NPT most common, also ⅛", ½" NPT, BSPT

- Electrical: ½" NPT conduit entry standard

- Terminals: Screw terminals for #14-#10 AWG wire

- Mounting: ¼" conduit knockout, panel mount, or surface mount

- Pressure Ranges: Vacuum to 6,000 PSI typical

How to Select Pressure Switch?

Fire Sprinkler Valve Tamper Switch Technical Specification:

- Pressure range and set point requirements

- Electrical specifications (voltage, current, contact arrangement)

- Fluid compatibility and temperature range

- Required accuracy and repeatability

- Environmental conditions (indoors/outdoors, hazardous areas)

- Certifications needed (UL, FM, CSA, ATEX)

Supplier Evaluation:

- Manufacturer certifications and industry reputation

- Product range and customization capabilities

- Technical support and application engineering

- Delivery lead times and availability

- Local distributor support

Documentation Requirements:

- Product data sheets with performance curves

- Material compatibility charts

- Installation and calibration instructions

- Certifications (UL, FM, etc.)

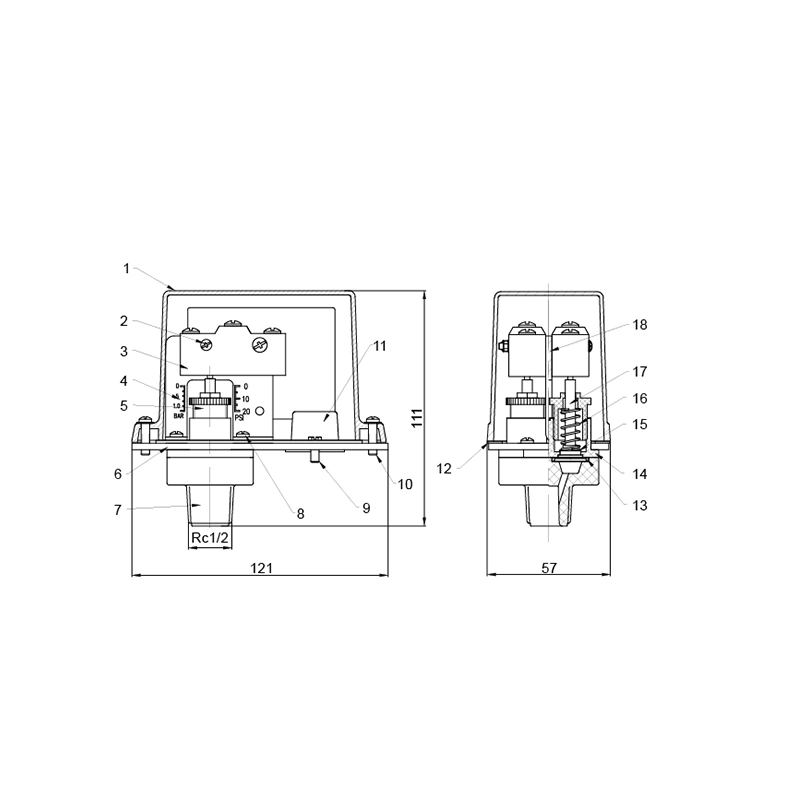

- Dimensional drawings

Commercial Considerations:

- Lead Time: 2-6 weeks standard, longer for custom

- Price: $50-$500 depending on features

- Warranty: 1-3 years typical

- Minimum Order: Usually 1 unit

- Delivery: Small parcel shipping typical

Pre-Shipment Inspection for Export Pressure Switch and Key Considerations

Inspection Checklist:

| Area | Procedure | Acceptance Criteria |

| Visual | External inspection | No damage, proper labeling |

| Mechanical | Adjustment test | Smooth operation, proper range |

| Electrical | Continuity test | Contacts operate correctly |

| Pressure | Calibration check | Trip at set point ± accuracy spec |

| Seals | Diaphragm/seal check | No leaks, proper installation |

| Mounting | Connection check | Threads clean, undamaged |

| Packaging | Export readiness | Proper protection, documentation |

Export Precautions:

- Pressure Testing: Ensure proper calibration before shipment

- Moisture Protection: Silica gel packs in packaging

- Vibration Protection: Foam padding for delicate components

- Documentation: Include calibration certificates

- Regulatory Compliance: Proper markings for destination country

Real-World Industrial Application:

In this boiler plant scenario, three distinct pressure switches provide layered protection:

- Operating Control Switch: Fine-tunes boiler operation for efficiency

- High Pressure Safety Switch: Hard shutdown for emergency protection

- Low Pressure Alarm Switch: Early warning of developing problems

- This defense-in-depth approach ensures multiple layers of protection against boiler overpressure, which could lead to catastrophic failure. Each switch uses different sensing technologies (diaphragm, piston, bellows) to ensure diverse failure modes don't compromise overall safety.

Key Safety Features:

- Independent Operation: Each switch operates separately

- Manual Reset: Safety switches require physical reset

- Regular Testing: Mandated testing schedule

- Redundant Sensing: Multiple pressure measurement methods

- Fail-Safe Design: Switches fail to safe conditions

Critical Performance Metrics:

- Accuracy: ±1-2% for reliable operation

- Repeatability: Consistent trip points

- Response Time: Milliseconds for safety functions

- Durability: Millions of cycles for operating switch

- Environmental Resistance: Withstands steam, heat, vibration

This installation demonstrates best practices in industrial safety systems, where pressure switches provide reliable, cost-effective protection for high-risk equipment. The combination of control, alarm, and safety functions in a single instrumentation panel shows efficient system design that prioritizes both operational efficiency and personnel safety.

.png)

.png)