Sobre nós

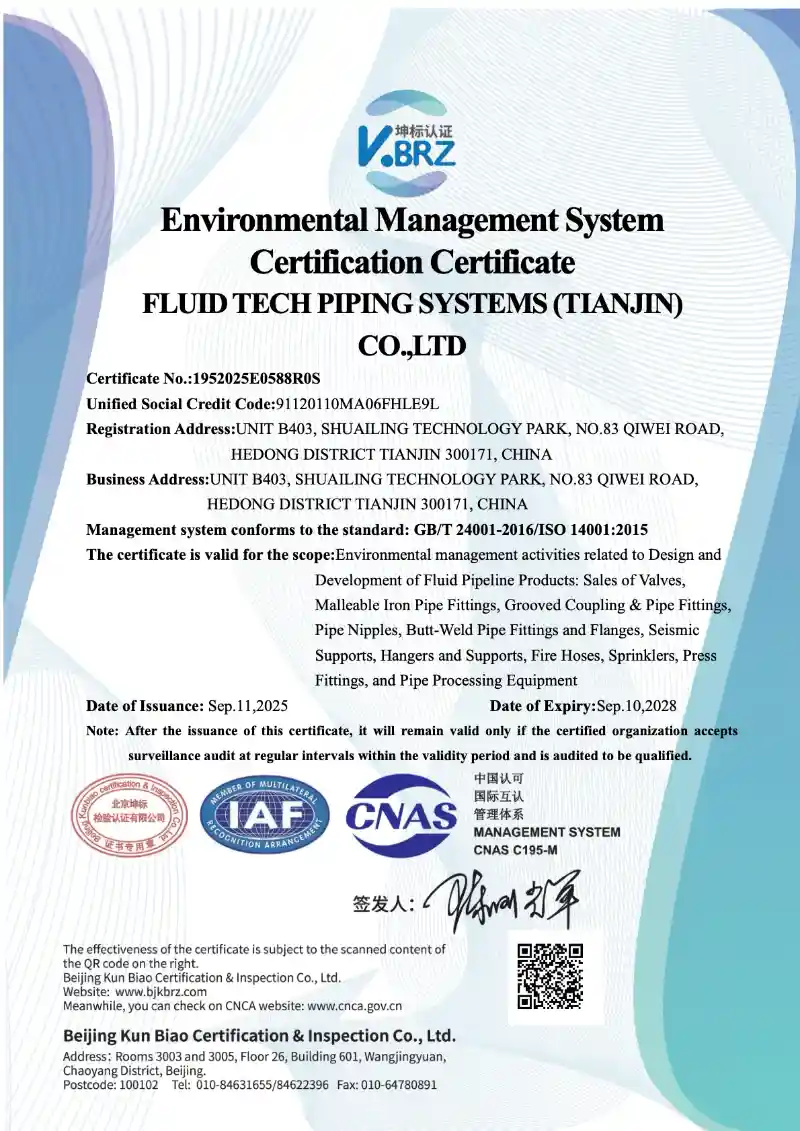

Até à data, a empresa passou nas auditorias de fábrica ISO, CE e SGS, e os seus produtos são certificados pela WARS. As válvulas de incêndio estão atualmente a solicitar a certificação UL/FM. O Grupo FLUID TECH inclui atualmente três marcas de produtos de válvulas: A marca FLUID TECH, a marca APEX e a marca B.

Wide Product Range & Global Reach

Válvulas de todos os tamanhos (DN15-DN4500) e materiais, exportadas para os principais mercados mundiais.

Professional R&D & High-Precision Manufacturing

Mais de 300 moldes, suporte OEM, fundição avançada e maquinação CNC, com válvulas testadas sob pressão 100%.

Fast Delivery & Stable Supply Chain

Forte apoio ao inventário, entrega normal em 25 dias, encomendas urgentes em 7 dias, com o apoio de um laboratório certificado pelo CNAS.

Reliable Quality & Cost-Effective for Customers

Sistema QC rigoroso, mais de 10 anos de garantia, ajudando os clientes a reduzir custos e a melhorar a competitividade.

As nossas vantagens

The valve factory primarily produces a wide size range of products (DN15–DN4500), including butterfly valves, fire signal butterfly valves, flanged end gate valves, grooved end gate valves, check valves, globe valves, ball valves, Y-strainers, balancing valves, fire alarm valves, deluge valves, pressure reducing valves, rubber expansion joints, air release valves, knife gate valves, and so on. Valve materials include ductile iron, gray iron, cast steel, stainless steel, and brass. Products are widely sold in Europe, the United States, the Middle East, Southeast Asia, South America, Africa, and countries along the “Belt and Road” initiative.

The APEX factory of FLUID TECH Group has its own independent R&D and design team, with over 300 sets of product molds. It offers custom design and OEM support. The valve bodies are cast using first-grade washed sand for mold and flask design, produced on advanced casting lines. After casting, valve bodies are polished with steel beads, manually inspected, and secondary polished. Machining is done using high-precision CNC machines along with some manual machining to ensure dimensional accuracy.

The factory has an independent spraying workshop capable of applying RAL3000 epoxy painting fire red color, RAL5005/RAL5015/RAL5017 epoxy painting blue color, and custom colors according to client requirements. There are 4 valve assembly lines and 10 pressure testing equipment units for valve sealing. Every valve undergoes 100% pressure testing, ensuring 100% pass rate before delivery.

Fast Delivery, Advanced Testing, and Long-Term Quality Assurance:

The factory maintains strong inventories, enabling standard orders to be delivered within 25 days and urgent orders within 7 days. Its in-house CNAS-accredited laboratory conducts chemical composition analysis, valve body strength and pressure tests, rubber aging and tensile tests, and more. With standardized production, strict inspection procedures, a robust quality management system, and comprehensive after-sales service, all valve products come with a warranty of over 10 years.

Safety-Driven Mission and High-Value Supply Chain Advantage:

FLUID TECH Group is committed to providing safe and reliable fluid transportation products—ensuring every household plumbing system and every project pipeline system is secure. Its professional and resilient supply chain helps customers reduce procurement costs and obtain higher-value products, strengthening market competitiveness and supporting them in gaining market share, customers, and reputation.

Certificados

Exposições

Faça parceria com a FLUID TECH para se tornarem aliados estratégicos - explorem o mercado juntos, cresçam juntos e colham o sucesso juntos.

Contact us now!

.png)

.png)