О нас

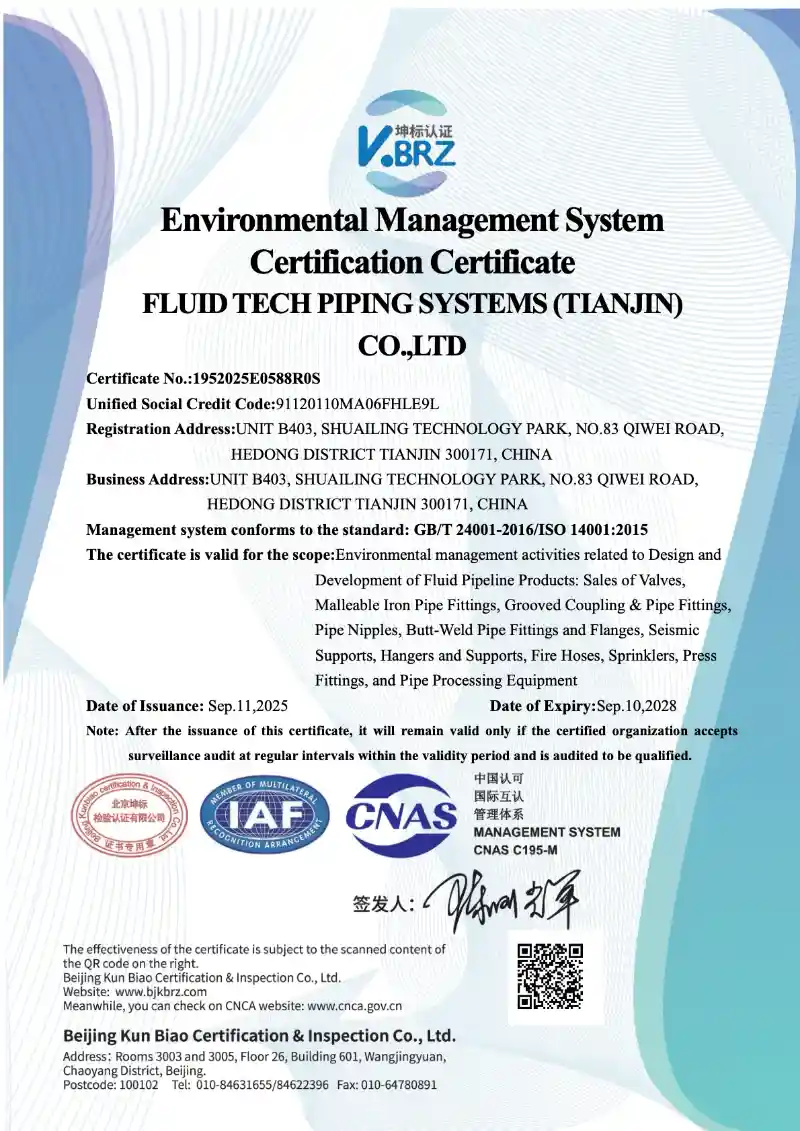

На сегодняшний день компания прошла аудиты заводов ISO, CE и SGS, а ее продукция сертифицирована WARS. В настоящее время пожарные клапаны подают заявку на сертификацию UL/FM. В настоящее время группа компаний FLUID TECH Group включает в себя три бренда клапанов: Бренд FLUID TECH, Бренд APEX и Бренд B.

Wide Product Range & Global Reach

Все типоразмеры клапанов (DN15-DN4500) и материалы, экспортируемые по всему миру на основные рынки.

Professional R&D & High-Precision Manufacturing

300+ пресс-форм, поддержка OEM, передовое литье и обработка с ЧПУ, с клапанами, проверенными давлением 100%.

Fast Delivery & Stable Supply Chain

Сильная поддержка запасов, стандартная доставка за 25 дней, срочные заказы за 7 дней, при поддержке лаборатории, сертифицированной CNAS.

Reliable Quality & Cost-Effective for Customers

Строгая система контроля качества, более чем 10-летняя гарантия, помогающая клиентам снизить затраты и повысить конкурентоспособность.

Наши преимущества

The valve factory primarily produces a wide size range of products (DN15–DN4500), including butterfly valves, fire signal butterfly valves, flanged end gate valves, grooved end gate valves, check valves, globe valves, ball valves, Y-strainers, balancing valves, fire alarm valves, deluge valves, pressure reducing valves, rubber expansion joints, air release valves, knife gate valves, and so on. Valve materials include ductile iron, gray iron, cast steel, stainless steel, and brass. Products are widely sold in Europe, the United States, the Middle East, Southeast Asia, South America, Africa, and countries along the “Belt and Road” initiative.

The APEX factory of FLUID TECH Group has its own independent R&D and design team, with over 300 sets of product molds. It offers custom design and OEM support. The valve bodies are cast using first-grade washed sand for mold and flask design, produced on advanced casting lines. After casting, valve bodies are polished with steel beads, manually inspected, and secondary polished. Machining is done using high-precision CNC machines along with some manual machining to ensure dimensional accuracy.

The factory has an independent spraying workshop capable of applying RAL3000 epoxy painting fire red color, RAL5005/RAL5015/RAL5017 epoxy painting blue color, and custom colors according to client requirements. There are 4 valve assembly lines and 10 pressure testing equipment units for valve sealing. Every valve undergoes 100% pressure testing, ensuring 100% pass rate before delivery.

Fast Delivery, Advanced Testing, and Long-Term Quality Assurance:

The factory maintains strong inventories, enabling standard orders to be delivered within 25 days and urgent orders within 7 days. Its in-house CNAS-accredited laboratory conducts chemical composition analysis, valve body strength and pressure tests, rubber aging and tensile tests, and more. With standardized production, strict inspection procedures, a robust quality management system, and comprehensive after-sales service, all valve products come with a warranty of over 10 years.

Safety-Driven Mission and High-Value Supply Chain Advantage:

FLUID TECH Group is committed to providing safe and reliable fluid transportation products—ensuring every household plumbing system and every project pipeline system is secure. Its professional and resilient supply chain helps customers reduce procurement costs and obtain higher-value products, strengthening market competitiveness and supporting them in gaining market share, customers, and reputation.

Сертификаты

Выставки

Partner with FLUID TECH to become strategic allies—explore the market together, grow together, and reap success together.

Contact us now!

.png)

.png)