Mechanical Joint Resilient Seated NRS Gate Valve with Indicator Post

Mechanical Joint Resilient Seated NRS Gate Valve with Indicator Post Definition and Components

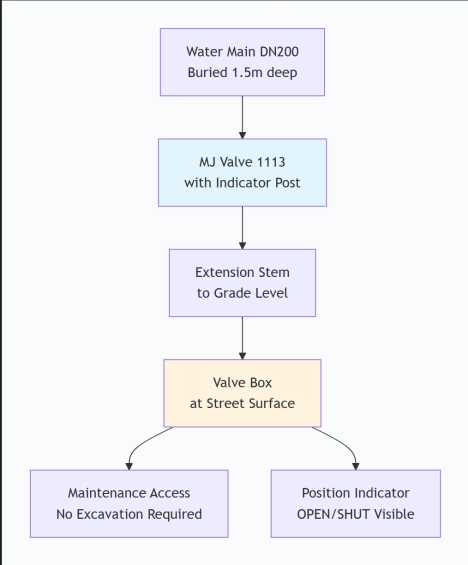

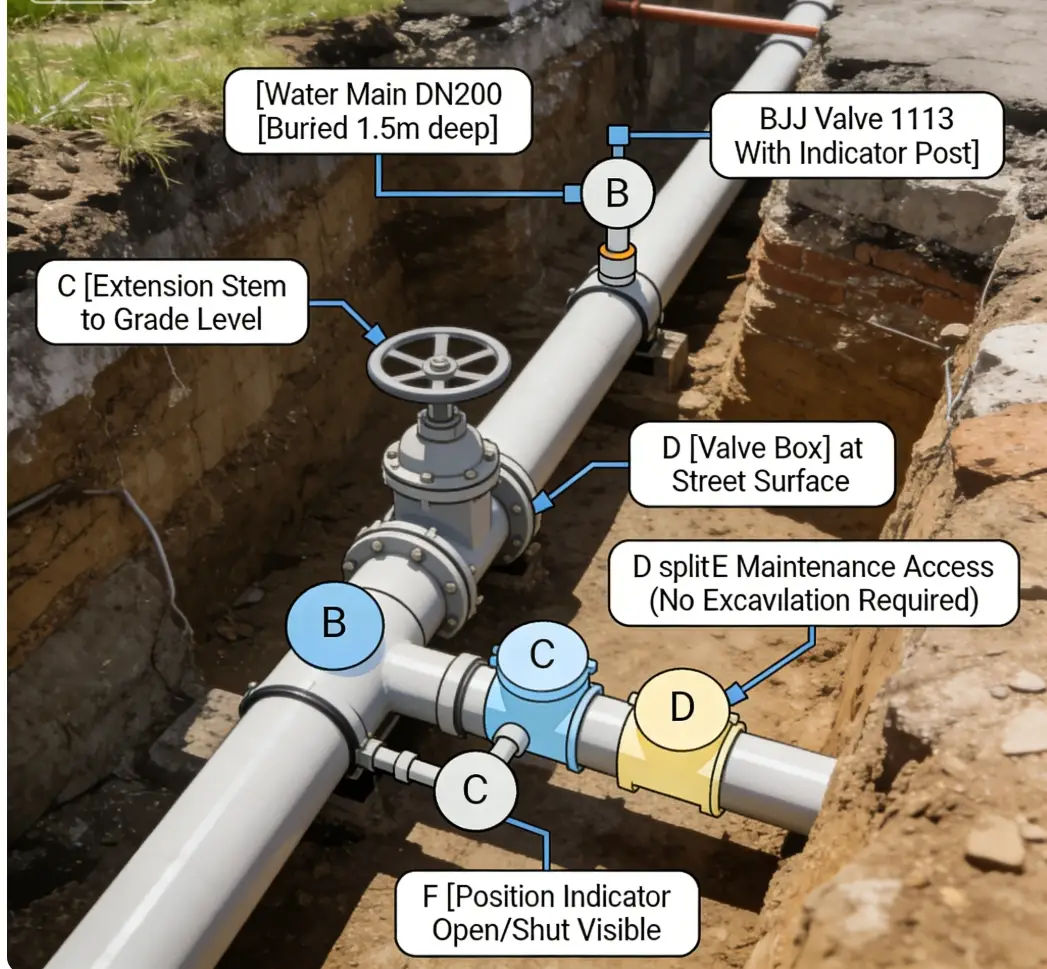

A Mechanical Joint Resilient Seated ul/fm NRS Gate Valve with Indicator Post (Model 1113) is a buried water valve that can be operated from ground level. It combines a standard mechanical joint valve with an extension stem and protective post.

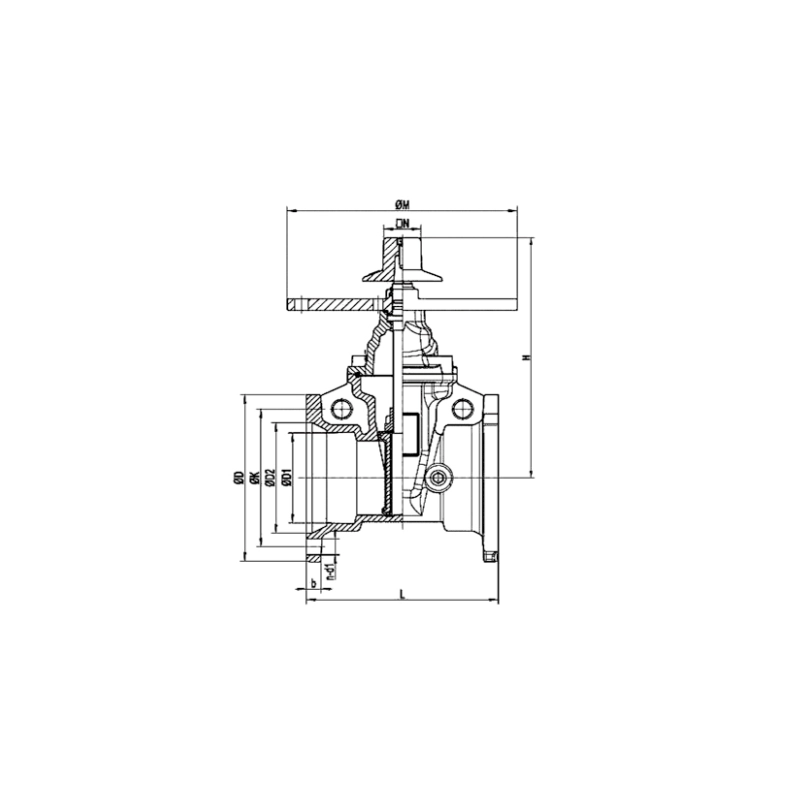

Main Parts:

Valve body with MJ ends

Resilient-seated gate

Long extension stem

Indicator post (steel pipe)

Ground-level operating nut with position indicator

Protective valve box/cover

Role, Characteristics, and Application Scenarios of Mechanical Joint Resilient Seated NRS Gate Valve with Indicator Post in Pipelines

Fire gate valve Functions:

Buried pipeline isolation

Above-ground operation

Visual position indication

Emergency shutdown access

Operational Features:

No excavation needed

Corrosion protected

Lockable cover option

Full port design

Fire valve Typical Applications:

Underground water mains

Street valve installations

Fire protection systems

Subdivision isolation points

Scenario Diagram:

Mechanical Joint Resilient Seated NRS Gate Valve with Indicator Post Standards: Materials, Design, and Connections

Material Standards:

Body/Gate: ASTM A536 Ductile Iron

Stem: ASTM A276 Stainless Steel

Post: ASTM A53 Galvanized Steel

Seat: EPDM (NSF/61 approved)

Design Standards:

Primary: AWWA C509

Pressure: 150/200 psi standard

Burial: AWWA C550 coating

Connection Standards:

Mechanical Joint: AWWA C111

Pipe Compatibility: AWWA C110/C151

End Type: MJ x MJ (both ends)

How to Select Mechanical Joint Resilient Seated NRS Gate Valve with Indicator Post

Key Steps:

Specify: Size, pressure, post length, burial depth

Verify Standards: AWWA C509 compliance mandatory

Select Supplier: Experienced in buried valve packages

Request Documents: AWWA certs, NSF/61, material reports

Review Drawing: Confirm post length and details

Critical Specifications:

Post length (from valve center to grade)

Valve box type (traffic-rated or standard)

Locking mechanism required

Soil condition for coating selection

Lead Time: Typically 10-16 weeks for custom extensions.

Pre-Shipment Inspection for Export Mechanical Joint Resilient Seated NRS Gate Valve with Indicator Post and Key Considerations

Documentation Check:

AWWA C509 Certificate

NSF/61 Certification

Material Test Reports (ASTM)

Hydrostatic Test Certificates

Physical Inspection:

Dimensional Verification

Post length (match order)

MJ bell dimensions

Face-to-face measurement

Pressure Testing

Shell test: 2× rated pressure

Seat test: 1.1× rated pressure

Zero leakage requirement

Operational Test

Smooth operation through extension

Indicator accuracy (open/shut)

Torque within limits

Coating Inspection

Internal epoxy: 8-12 mils thickness

External protection per spec

No holidays or defects

Export Packaging:

Indicator post must be supported in crate

Operating nut wrapped separately

Valve box packaged individually

VCI bags in valve cavity

Desiccant for humid destinations

Wooden crate with lifting points

Key Precautions:

Long items: Special reinforcement in container

Thread protection: Caps on all exposed threads

Climate: Extra moisture protection for humid regions

Instructions: Include detailed burial/installation guide

Final Documents for Shipment:

Commercial Invoice

Packing List

Bill of Lading

Certificate of Origin

Complete technical file (certs, reports)

Installation Manual

.png)

.png)