Single Opening Air Valve P41X

Single Opening Air Valve P41X Purpose

This Single Air Valve installed on pipe peak or there is breath, is used to eliminate the gas of pipe to pipe functioning as power outages, stop the pump, the valve inlet timely, ensure the security of the pipeline.

Single Opening Air Valve P41X Feature

Single opening exhaust valves small in size and light in weight, Row of inspiratory volume.

Single Opening Air Valve P41X Definition and Components

What is a Single Opening Air Valve P41X and its Main Parts?

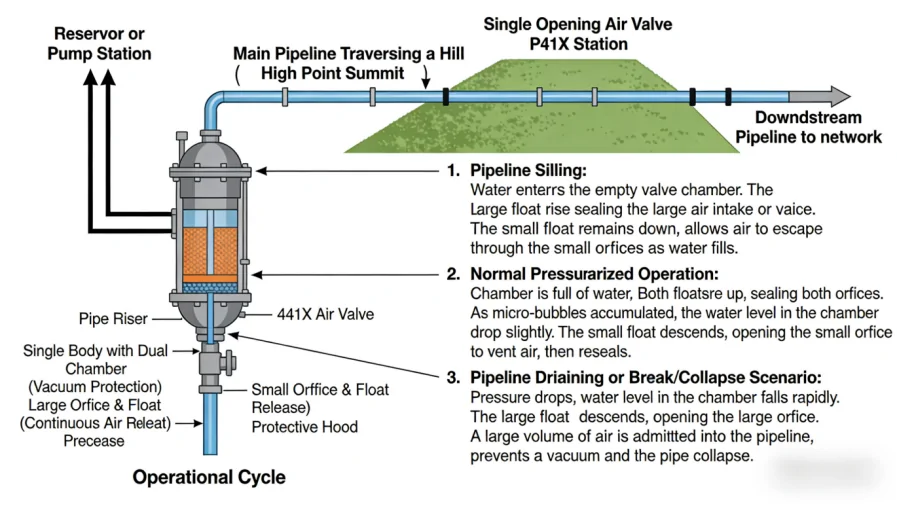

A Single Opening Air Valve P41X (often called a Combination Air Valve or Double Function Air Valve) is an automatic valve that performs two critical functions through a single pipeline connection: 1) releasing air during system operation, and 2) admitting air during system drainage to prevent vacuum formation. The "P41X" is a common model series designation from manufacturers.

Water Valves Main Components:

- Single Valve Body: A compact chamber with one main inlet/outlet for pipeline connection and an air discharge/admission port. This single-orifice design distinguishes it from more complex "triple-function" valves.

- Air Release Mechanism: A small orifice with a float and lever assembly (similar to the micro air valve). It automatically vents accumulated air under pressure during normal operation.

- Large Air Vacuum Mechanism: A large orifice controlled by a large float or rolling seal. It opens rapidly to admit large volumes of air when the pipeline is being drained or when vacuum conditions occur, preventing pipeline collapse

- Dual Float Chamber: Houses both float mechanisms in a single compartment.

- Protective Hood or Cap: Covers the discharge/admission port(s) to prevent debris and insect ingress while allowing air flow

Role, Characteristics, and Application Scenarios of Single Opening Air Valve P41X in Pipelines

Functions, Operational Features, and Usage Scenarios

Air Valve for Water Functions in Pipelines:

- Automatic Air Release (Small Orifice): Vents small pockets of air that accumulate at high points during pipeline pressurization and operation.

- Automatic Air Intake (Large Orifice): Admits large volumes of air during pipeline emptying to prevent the formation of a dangerous vacuum, which can collapse pipes or draw in contaminated water through leaks.

- Pipeline Protection: Safeguards the pipeline from both air-related problems (cavitation, flow reduction) and vacuum-related damage (collapse).

Operational Features:

- Dual-Function, Single Connection: Simplifies installation and reduces cost compared to installing two separate valves.

- Fully Automatic: No external power or control required.

- Sequential Operation: During filling, the large orifice closes as water enters. During operation, the small orifice vents micro-bubbles. During draining, the large orifice opens to admit air.

- Robust Design: Built to handle the surge conditions that can occur during air intake.

Typical Usage Scenarios:

- Water Transmission & Distribution Mains: At all prominent high points where air naturally collects and where vacuum risk exists during shutdown.

- Pump Discharge Lines: To release air after pump start-up and admit air upon pump stoppage.

- Irrigation Systems: On mainlines to ensure efficient filling and safe draining.

- Sewage Force Mains: To manage air and gas release (often with special coatings/seals).

Industrial Process Lines: Where both air removal and vacuum protection are needed for process integrity.

Single Opening Air Valve P41X Standards: Materials, Design, and Connections

Material, Design, and Connection Standard

Material Standards:

- Body & Cover: Ductile Iron (ASTM A536) with epoxy coating (AWWA C550), Cast Iron (ASTM A126), or Stainless Steel (AISI 304/316) for corrosive environments.

- Floats: Stainless Steel (AISI 304/316) or Polypropylene.

- Internal Mechanism & Pins: Stainless Steel.

- Seals (O-rings, Seat Discs): EPDM (standard water), NBR, or Viton for wastewater or high temperatures.

Design & Performance Standards:

- General Performance: AWWA C512 (Standard for Air-Release, Air/Vacuum, and Combination Air Valves for Waterworks Service) is the primary governing standard in North America. ISO 22149 is an emerging international standard.

- Pressure Rating: Typically PN10/16/25 (Class 125/150/300). Designed per ASME B16.34 or equivalent.

- Capacity Certification: Performance (air release and intake capacity) should be tested per AWWA C512 or ISO 22149 protocols.

- Face-to-Face: Often custom, but designed to fit standard pipe risers.

Connection Standards:

- Flanged Inlet: Predominant. ASME B16.1 Class 125/250 or ASME B16.5 Class 150. Drilling per ANSI or ISO.

- Threaded Inlet: For smaller sizes (2" and below), NPT (ASME B1.20.1) or BSP threads.

- Air Discharge Port: Usually a threaded connection (e.g., NPT ¾") fitted with a protective hood.

How to Select Single Opening Air Valve P41X

Procurement Process

Define Critical Application Parameters:

- Pipeline Data: Nominal diameter, maximum operating pressure, material.

- Flow Conditions: Maximum filling and emptying flow rates. This is critical for sizing the large orifice to admit enough air to prevent vacuum

- Installation Location: High point, pump discharge, etc. This defines the required functions.

- Fluid: Potable water, wastewater, other fluids (affects material/coating selection).

- Sizing: Provide data to the manufacturer. They will use formulas (often based on the air-to-water flow ratio) to select the correct valve size, which is typically 1/2 to 1/4 of the pipeline diameter.

Supplier Selection:

Choose manufacturers specializing in pipeline air valves with a strong reputation in waterworks (e.g., APCO, Val-Matic, GA, Bermad, ARI).

Verify they design and test per AWWA C512 or equivalent.

Technical Review:

Request and review the manufacturer's sizing calculations for the large orifice air admission capacity.

Examine GA drawings, material specifications, and coating certificates.

Confirm the design includes stainless steel internals and an epoxy-coated body as a minimum for water service.

Commercial & Logistics:

Lead times: 8-16 weeks.

- Order a complete assembly: Often includes isolation valves (ball or gate), a pipe nipple/riser, and a drain valve as a package.

- Spare Parts Kit: Essential to purchase complete seal and O-ring kits for each valve, and possibly a spare small orifice float assembly.

Support Requirements:

Demand detailed installation instructions specifying vertical mounting and required clearance for hood removal.

Request the certified air capacity chart for the supplied valve size.

Pre-Shipment Inspection for Export Single Opening Air Valve P41X and Key Considerations

Pre-Shipment Inspection & Export Precautions

- Inspection & Testing Checklist (FAT is highly recommended):

- Documentation Review: Verify AWWA C512 compliance statement (if specified), MTRs for body and floats, epoxy coating certificate, and test reports.

- Visual & Dimensional: Check for proper coating, correct flange rating/drilling, clear nameplate data (size, pressure rating), and that the protective hood is unattached but included.

Critical Functional Tests:

- Shell Hydrostatic Test: Per AWWA C512, test the body at 1.5x rated pressure.

- Seat Tightness Test (Submerged Test): Submerge the assembled valve in water. Apply air pressure internally. Verify no bubbles leak from either the small or large orifice seals when the valve is in the "closed" (liquid-filled) position.

- Float & Mechanism Operation Test: Manually simulate the filling and draining cycle to ensure both floats move freely and the levers/seats operate smoothly without binding

Key Precautions for Export

- Internal Preservation: The valve must be completely drained, dried, and preserved internally with a VPI spray. Any residual water will cause corrosion during transit.

- Float Securing (CRITICAL): The large float must be securely blocked or tied down using manufacturer-supplied shipping restraints. If left loose, it will bounce violently during transport, likely damaging the lever mechanism and seat, rendering the valve inoperable.

- Orifice & Port Protection: The air discharge port must be sealed with a sturdy plastic cap. All threaded connections must be plugged.

- Flange Protection: Use bolted-on wooden or rigid plastic covers for the main pipeline flange.

- Crating: Pack the valve vertically (as it operates) in a strong wooden crate with internal blocking to prevent any movement. Include desiccant bags. Pack the protective hood separately in the same crate.

- Clear Markings: Mark the crate with "AIR VALVE," "PROTECT FROM IMPACT," "KEEP DRY," and "THIS SIDE UP." Include a waterproof pouch with manuals, test reports, and the packing list inside the crate.

Single Opening Air Valve P41X Main dimensions(mm)

| DN | A | D | D1 | D2 | b | f | n-Фd | H |

| 50 | 140 | 160 | 125 | 99 | 17 | 3 | 4-18 | 230 |

| 65 | 140 | 180 | 145 | 118 | 17 | 3 | 4-18 | 235 |

| 80 | 140 | 195 | 160 | 132 | 17 | 3 | 8-18 | 250 |

| 100 | 180 | 215 | 180 | 156 | 17 | 3 | 8-18 | 255 |

| 125 | 180 | 245 | 210 | 184 | 18 | 3 | 8-18 | 255 |

| 150 | 180 | 280 | 240 | 211 | 18 | 3 | 8-23 | 260 |

| 200 | 295 | 335 | 290 | 266 | 24 | 3 | 12-23 | 300 |

| 250 | 295 | 405 | 355 | 320 | 24 | 3 | 12-28 | 340 |

| 300 | 295 | 460 | 410 | 370 | 24 | 3 | 12-28 | 340 |

Note:1. Other specifications and flange standards are available upon request.

- Design and specifications are subject to change without prior notice.

.png)

.png)