Slurry Knife Gate Valve GCU73

Slurry Knife Gate Valve Purpose

The Slurry Knife Gate Valve has simple structure, small size, light weight, small flow resistance, and the medium is not easy to pre cipitate in the valve body, As well as many advantages such as easy installation, while having manual and electro-hydraulic operation functions. Electrical control: stroke switch control, position display instrument control, the realization of machine, electrical, hydraulic, instrument integration and other multi-functional system. This type of valve should generally be installed horizontally in the pipeline.Widely used in mining, iron and steel industry, purification equipment, paper industry,sugar industry, food industry and so on.

Main part materials

| Title of part | Material |

| Body/Bonnet | Ductile iron |

| Gate | Ductile iron |

| Stem | Stainless steel |

| Sealing face | Rubber.PTFE,Stainless steel. Carbide alloy |

Slurry Knife Gate Valve Definition and Components

What is a Slurry Knife Gate Valve GCU73 and its main parts?

- A Slurry Knife Gate Valve GCU73 is a type of valve specifically designed to control the flow of abrasive, viscous, or high-solid-content slurries in pipeline systems. Its defining feature is a sharp, blade-like gate that cuts through thick media to provide a tight shut-off. The main parts typically include:

- Valve Body: Often a one-piece or heavy-duty construction to withstand abrasion and pressure.

- Gate/Blade: A hardened, sharp-edged plate (often made of stainless steel with hardened edges or coated with wear-resistant materials) that moves linearly to open or close the flow path.

- Stem: A threaded or rising stem connected to the gate, transmitting the actuation force.

- Seat/Sealing System: Resilient seals (e.g., rubber, polyurethane) or metal-to-metal seats that ensure tight closure around the gate. Many slurry valves have replaceable elastomeric sleeves or seat rings.

- Packing Box/Gland: A sealing assembly around the stem to prevent external leakage.

- Bonnet/Actuator Mounting: The top section housing the stem and providing a platform for mounting manual hand wheels, gear operators, or pneumatic/hydraulic/electric actuators.

- Flanges or Lug/Wafer Ends: For connection to the pipeline (specific to GCU73 model design).

Role, Characteristics, and Application Scenarios of Slurry Knife Gate Valve in Pipelines

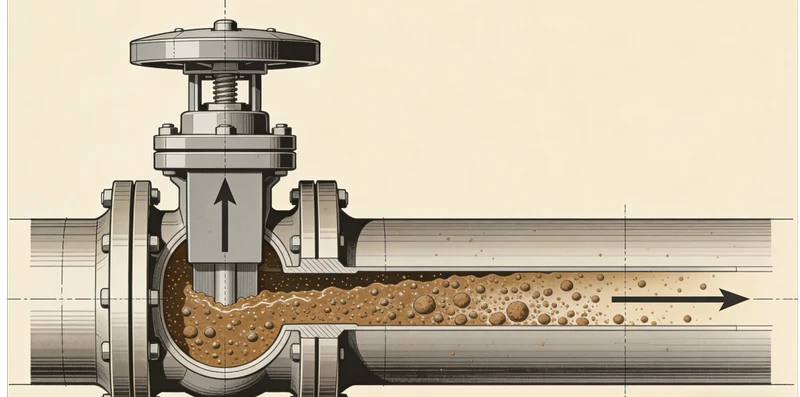

Functions, Operational Features, Usage Scenarios, and Scenario Diagram

Water Valves Functions: Primarily provides reliable on/off isolation for slurry services. It is designed to minimize clogging, offer a full-bore flow path when open (reducing pressure drop), and achieve tight shut-off against difficult media.

Operational Features:

- Linear Motion: The gate moves in a straight line, perpendicular to the flow.

- Shearing Action: The sharp gate can cut through and dislodge solid particles that might cause clogging.

- Sealing Mechanism: Often uses a flexible, energized seal that compresses around the gate for tight closure, even with minor solids buildup.

- Robust Construction: Built with abrasion-resistant materials and extra clearance to handle wear.

- Usage Scenarios: Widely used in industries handling abrasive or dense fluids:

- Mining & Mineral Processing: Tailings, ore slurries, thickener underflow.

- Power Plant: Fly ash, bottom ash slurry.

- Wastewater Treatment: Sludge, grit, and thickened biosolids.

- Pulp & Paper: Stock, pulp suspensions.

- Chemical Processing: Abrasive chemical slurries.

Slurry Knife Gate Valve Standards: Materials, Design, and Connections

Material, Design, and Connection Standards

Knife Gate Valve Material Standards:

- Body/Bonnet: Cast carbon steel (e.g., ASTM A216 WCB), cast stainless steel (e.g., ASTM A351 CF8/CF8M), or specialty abrasion-resistant steels.

- Gate: 410/420 stainless steel with hardened edges, or carbon steel with ceramic or hard alloy coatings (e.g., Stellite).

- Seats/Seals: EPDM, Nitrile, Polyurethane, or Viton for resilience and wear resistance.

- Stem: 304/316 stainless steel or forged carbon steel.

- Design Standards: Commonly follows MSS SP-81 "Knife Gate Valves - Flanged, Lug, Wafer, and Butt-welding Ends". It may also incorporate features per ISO 16136 or manufacturer-specific standards for slurry service.

- Connection Standards: The "GCU73" model typically indicates a specific flange connection.

- Flange Standards: ASME B16.5 (Class 150/300) or EN 1092-1 (DIN) (PN10/PN16/PN25) are common.

It may also be of Lug or Wafer type for easier installation between pipeline flanges.

How to Select Slurry Knife Gate Valve

How to Purchase

- Define Specifications: Clearly determine pipeline size (DN/ NPS), pressure class (PN/ Class), operating temperature, and the specific slurry characteristics (particle size, abrasiveness, pH, concentration). Specify actuation method (manual, pneumatic, electric).

- Identify Reputable Suppliers: Source from specialized industrial valve manufacturers known for slurry handling equipment. Verify quality certifications (ISO 9001, API, CE).

- Request Quotations & Technical Data: Provide your specs to suppliers. Request detailed material breakdowns, trim specifications, torque data, and certifications (e.g., material test reports).

- Evaluate & Order: Compare offers based on technical suitability for the duty, lead time, price, and warranty. Ensure the purchase order explicitly lists all critical specifications and standards

Pre-Shipment Inspection for Export Slurry Knife Gate Valve and Key Considerations

Pre-Export Inspection and Precautions

Inspection Protocol:

- Visual & Dimensional Check: Verify cleanliness, absence of damage, correct markings, and flange dimensions/face finish.

- Material Verification: Check material certificates against order requirements.

- Function & Pressure Test: Operate the valve through full cycles to ensure smooth action. Perform a shell test (body pressure test) and a seat leakage test per standard (e.g., API 598, ISO 5208) to confirm integrity. For slurry valves, low-pressure air seat testing is often critical.

- Actuator Check (if fitted): Verify alignment, operation, and settings.

- Packaging Inspection: Ensure valves are internally protected (e.g., VCI paper, desiccant) and externally crated in robust, weather-proof wooden cases suitable for ocean freight. All moving parts should be secured.

Precautions:

- Ensure the valve is in the closed position during shipping to protect the sealing faces.

- Preserve/Protect all exposed stems, flange faces, and mating surfaces from rust and impact damage.

- Include complete documentation (packing list, invoice, certificates, manuals) in a waterproof pouch inside the packaging.

- Clearly mark handling instructions (e.g., "Lift Here," "Keep Dry") and shipping marks on the exterior.

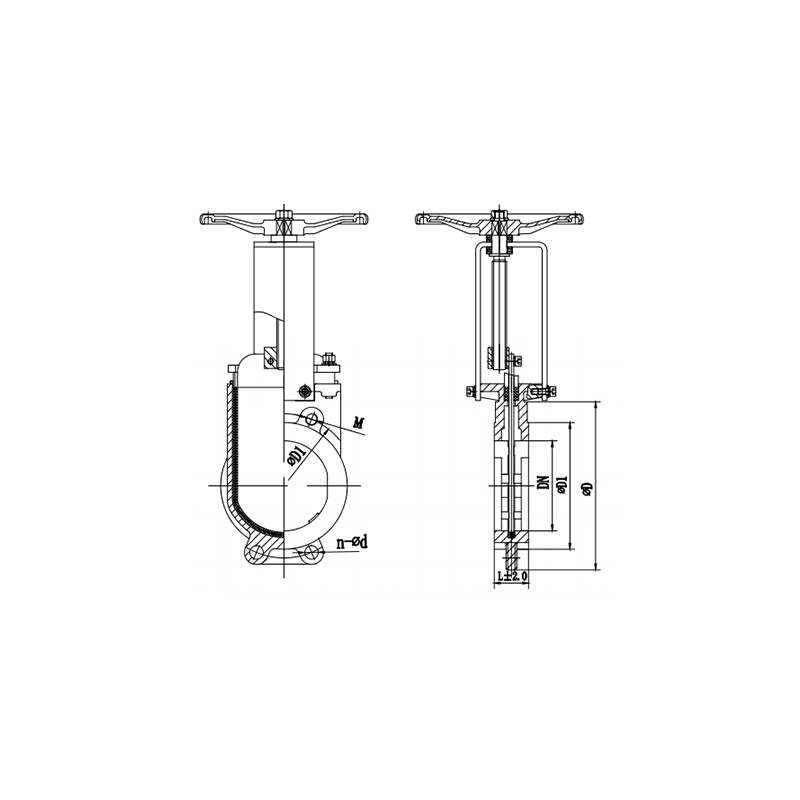

Slurry Knife Gate Valve Main dimensions(mm)

| DN | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 700 | 800 | 900 | |

| L | 48 | 48 | 51 | 51 | 57 | 57 | 70 | 70 | 76 | 76 | 89 | 89 | 114 | 114 | 127 | 127 | 154 | |

| D | PN10 | 165 | 185 | 200 | 220 | 250 | 285 | 340 | 395 | 445 | 505 | 565 | 615 | 670 | 780 | 895 | 1015 | 1115 |

| PN16 | 165 | 185 | 200 | 220 | 250 | 285 | 340 | 405 | 460 | 520 | 580 | 640 | 715 | 840 | 910 | 1025 | 1125 | |

| 150Lb | 150 | 180 | 190 | 230 | 255 | 280 | 345 | 405 | 485 | 535 | 595 | 635 | 700 | 815 | ||||

| D1 | PN10 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 350 | 400 | 460 | 515 | 565 | 620 | 725 | 840 | 950 | 1050 |

| PN16 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 355 | 410 | 470 | 525 | 585 | 650 | 770 | 840 | 950 | 1050 | |

| 150Lb | 120.7 | 139.7 | 152.4 | 190.5 | 215.9 | 241.3 | 298.5 | 362 | 431.8 | 476.3 | 539.8 | 577.9 | 635 | 749.3 | ||||

| n-Фd | PN10 | 4-18 | 8-18 | 8-18 | 8-18 | 8-18 | 8-22 | 8-22 | 12-22 | 12-22 | 16-22 | 16-26 | 20-26 | 20-26 | 20-30 | 24-30 | 24-33 | 28-33 |

| PN16 | 4-18 | 4-18 | 8-18 | 8-18 | 8-18 | 8-22 | 12-22 | 12-26 | 12-26 | 16-26 | 16-30 | 20-30 | 20-33 | 20-36 | 24-36 | 24-39 | 28-39 | |

| 150Lb | 4-19 | 4-19 | 4-19 | 8-19 | 8-22 | 8-22 | 8-22 | 12-26 | 12-26 | 12-29 | 16-29 | 16-32 | 20-32 | 20-35 | ||||

Note:1. Other specifications and flange standards are available upon request.

- Design and specifications are subject to change without prior notice.

.png)

.png)