Threaded Cast lron Globe Valve

Threaded Cast lron Globe Valve Definition and Components

What is a Threaded Cast Iron Globe Valve and its main parts?

A Threaded Cast Iron Globe Valve is a compact, economical valve designed for on/off and basic throttling service in low to medium-pressure piping systems. It is characterized by a cast iron body and bonnet and threaded (screwed) end connections, typically conforming to NPT (National Pipe Taper) or BSPT (British Standard Pipe Taper) standards. It is a manually operated, linear motion valve where the disc moves perpendicular to the seat.

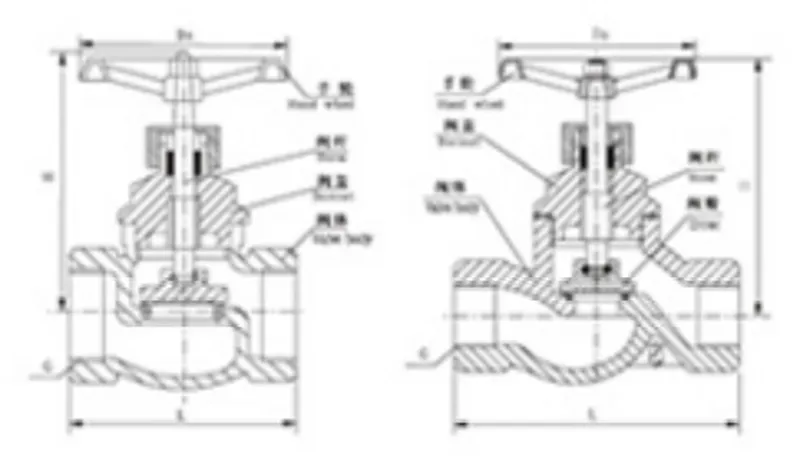

Threaded Globe Valve Main Parts:

- Body: The main housing, cast from gray cast iron (e.g., ASTM A126 Class B), containing the internal flow passage and female threaded ends.

- Bonnet: The cover, also cast iron, which houses the stem sealing assembly and is screwed or bolted to the body.

- Disc (Plug): The closure element, often with a flat or tapered face made of brass, bronze, or stainless steel for better wear resistance.

- Stem: A threaded stem (usually rising stem design) that connects the handwheel to the disc.

- Seat: The sealing surface against which the disc closes. It may be integral to the body or a separate, replaceable ring (often made of brass or bronze).

- Packing Gland: The assembly that compresses packing material (e.g., graphite, PTFE) around the stem to prevent leakage.

- Handwheel: For manual operation.

Role, Characteristics, and Application Scenarios of Threaded Cast lron Globe Valve in Pipelines

Functions, Operational Features, Usage Scenarios, and Scenario Diagram

Functions: Primarily used for isolation (shut-off) and, to a limited degree, flow throttling in small-bore pipelines. It provides more precise flow control than a gate valve but with higher pressure loss.

Operational Features:

- Moderate Pressure Drop: The Z-shaped flow path creates more resistance than a gate valve.

- Good Shut-Off: Provides tighter sealing than a basic gate valve, suitable for frequent operation.

- Simple Installation: Threaded ends allow for easy installation without welding or flanging.

- Limited Pressure/Temperature Rating: Due to cast iron material, it is not suitable for high pressure, thermal shock, or severe cyclic duty.

- Usage Scenarios: Ideal for general utility services in non-critical, non-shock applications.

- Building Services: HVAC chilled/hot water lines, compressed air lines.

- Industrial Plumbing: Low-pressure steam, water, oil, or gas lines.

- Process Utilities: Instrument air, service water, drain lines.

Irrigation Systems.

Threaded Cast lron Globe Valve Standards: Materials, Design, and Connections

Material, Design, and Connection Standards

Industrial valves Material Standards:

- Body/Bonnet: ASTM A126 Class B (Gray Iron Castings) or equivalent (e.g., EN-GJL-250).

- Trim (Disc, Seat, Stem): Brass (CZ132/CW617N), Bronze, or 304 Stainless Steel.

- Packing: Graphite, PTFE, or synthetic rubber.

Design Standards:

- API 602 (compact forged valves) or MSS SP-80 (Bronze Gate, Globe, Angle and Check Valves) are references, but many generic valves follow general industry patterns.

- ASME B16.34 may be referenced for pressure-temperature ratings, but cast iron ratings are lower.

Connection Standards:

- Thread Standard: ASME B1.20.1 for NPT (National Pipe Taper) threads is most common in North American markets. ISO 7-1 (BSPT) is common elsewhere.

- Pressure Rating: Typically rated for Class 125 or Class 150 service at saturated steam temperatures (~200°C/400°F max).

How to Select Threaded Cast lron Globe Valve

How to Purchase

- Define Basic Parameters: Determine size (NPS: ½", ¾", 1", etc.), pressure class (e.g., 150 WOG/125 SWP), fluid type, and temperature. Confirm threaded end standard (NPT or BSP).

- Identify Suppliers: Source from general valve distributors or manufacturers specializing in commercial/industrial valves. Certifications like ISO 9001 are beneficial.

- Request Key Information: Ask for a catalog sheet specifying materials, pressure-temperature chart, and dimensional data. For large quantities, request a sample.

- Evaluate & Order: Compare based on material specifications, conformity to stated standards, price, and availability. Ensure the purchase order clearly states size, material (cast iron body, brass trim), end connection, and pressure rating

Pre-Shipment Inspection for Export Threaded Cast lron Globe Valve and Key Considerations

Pre-Export Inspection and Precautions

Inspection Protocol:

- Visual & Dimensional Check: Inspect for casting flaws (sand holes, cracks). Verify size, and check thread quality (no chipped threads, proper taper) using a thread gauge.

- Material & Marking Check: Confirm "CF8M" or "WCB" markings are not present; look for cast iron designations. Check for a clear flow direction arrow.

- Function Test: Operate the handwheel through full cycles. Ensure smooth operation, no stem binding, and the disc seats properly.

- Hydrostatic Test: Perform a shell test (typically 1.5x rated pressure) and a seat leakage test (1.1x rated pressure). Cast iron valves are brittle, so pressure must be controlled carefully.

Precautions:

- Avoid Impact: Cast iron is brittle. Handle with care to prevent cracking. Mark crates with "Fragile."

- Protect Threads: Use heavy-duty plastic thread protectors on all connections. This is critical to prevent damage.

- Corrosion Protection: Apply a light rust preventive oil on machined surfaces if the storage environment is humid.

- Packaging: Pack individually in boxes with sufficient cushioning. For bulk shipments, use partitioned cartons or crates to prevent valves from knocking together.

- Documentation: Include a packing list and basic test reports (if performed). Ensure commercial invoices correctly describe the material as "Cast Iron."

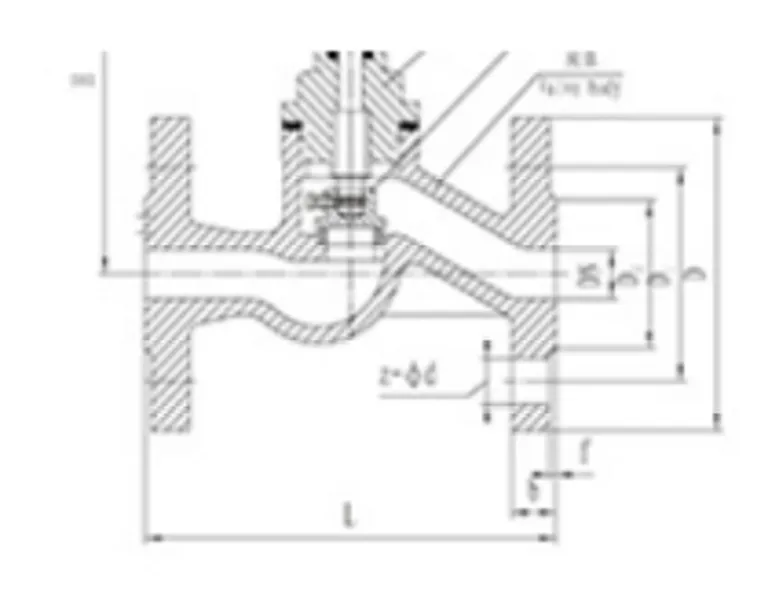

Outling and connect measurement

| Type | Nominal DN(mm) |

Measirement(mm) |

|||||||

| L | D | Di | D₂ | b-f | Z-φd | H | Do | ||

| 15 | 130 | 95 | 65 | 45 | 2月14日 | 4-φ14 | 113)200 | 80 | |

| J4IT/W/ H/F-16 |

20 | 150 | 105 | 75 | 55 | 16-2 | 4-φ14 | (113)200 | 80 |

| 25 | 160 | 115 | 85 | 65 | 16-2 | 4-φ14 | (125)220 | 80 | |

| 32 | 180 | 135 | 100 | 78 | 18-2 | 4-φ18 | (145)245 | 100 | |

| 40 | 200 | 145 | 110 | 85 | 18-3 | 4-φ18 | (180)260 | 130 | |

| 50 | 230 | 160 | 125 | 100 | 20-3 | 4-φ18 | (200)285 | 130 | |

| 65 | 290 | 180 | 145 | 120 | 20-3 | 4-φ18 | (205)300 | 150 | |

| 80 | 310 | 195 | 160 | 135 | 22-3 | 8-φ18 | 330 | 240 | |

| 100 350 215 180 | 350 | 215 | 180 | 155 | 24-3 | 8-φ18 | 350 240 | 240 | |

| 125 | 400 | 245 | 210 | 185 | 26-3 | 8-φ18 | 405 | 300 | |

| 150 | 480 | 280 | 240 | 210 | 28-3 | 8-φ23 | 450 | 300 | |

| 200 | 600 | 335 | 295 | 265 | 30-3 | 12-φ23 | 520 | 380 | |

| 250 | 650 | 405 | 355 | 320 | 32-3 | 12-φ25 | 710 | 420 | |

We also supply fire valve and water valves.

.png)

.png)