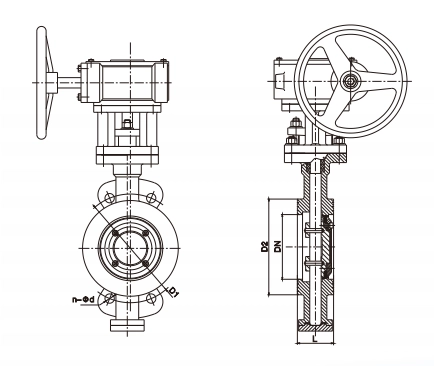

Wafer Metal-seat Butterfly Valve D373H/D373F

Wafer Metal-seat Butterfly Valve Purpose

This Metal Seat Butterfly Valve is used for the water supply and drainage system in tap water, sewage, building, chemicals. Industries, usually used as an open-close equipment. This product is used for the water supply and drainage system in tap water, sewage, building, chemicals. Industries, usually used as an open-close equipment.

Wafer Metal-seat Butterfly Valve Definition and Components

What is a Wafer Metal-seat Butterfly Valve D373H/D373F and its main parts?

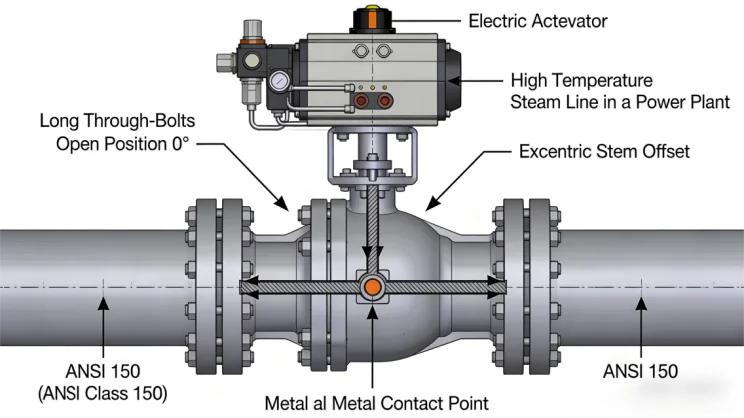

A Wafer Metal-seat Butterfly Valve D373H/D373F is a quarter-turn rotary valve designed for tight shut-off in demanding service conditions. The "Wafer" design means it is installed by clamping between two pipeline flanges, making it lightweight and compact. "Metal-seat" indicates that both the disc edge and the body seat ring are made of metal or hard alloys, enabling it to withstand high temperatures, abrasion, and corrosive fluids far beyond the limits of resilient (rubber) seat butterfly valves.

Industrial valves Main Parts:

- Body: A single-piece, wafer-style casing (typically cast) with a circular bore. It is designed to fit between ANSI/DIN flanges.

- Disc: The rotating closure element (often a double-eccentric or triple-eccentric design), usually made of stainless steel or carbon steel with a hardened or coated sealing edge.

- Metal Seat Ring: A precision-machined ring, often made of stainless steel (e.g., 304, 316) or harder alloys like Stellite, which is either integrally cast or welded into the body, forming the sealing surface against the disc.

- Stem: A one-piece or two-piece shaft that transmits torque from the actuator to the disc. It is sealed by packing or O-rings.

- Shaft Seals: Multiple sets of packing (graphite, PTFE) or spring-loaded seals to prevent external leakage along the stem.

- Bushings/Bearings: Low-friction bushings support the stem and disc, reducing operating torque.

- Actuator Mounting Pad: Standardized interface (ISO 5211) for mounting gear operators, pneumatic, hydraulic, or electric actuators.

- Note on D373H vs. D373F: The suffix often indicates specific material trim or seat type. Commonly, D373H denotes a valve with Stainless Steel (Cr13) seat/disc trim, while D373F denotes a valve with a more corrosion-resistant Stainless Steel (316) seat/disc trim. Exact specifications vary by manufacturer.

Role, Characteristics, and Application Scenarios of Wafer Metal-seat Butterfly Valve in Pipelines

Functions, Operational Features, Usage Scenarios, and Scenario Diagram

Functions: Primarily used for on/off isolation and throttling control in pipelines handling high-temperature, abrasive, or mildly corrosive media. It provides bubble-tight shut-off (or low leakage rates per API 598/ISO 5208) under challenging conditions.

Operational Features:

- High-Temperature Capability: Can typically operate from -29°C to over 425°C, depending on seat materials and design.

- Abrasion & Corrosion Resistance: The hard metal seat resists wear from particles and erosion.

- Eccentric Design: Most metal-seat butterfly valves use a double or triple eccentric design. This geometry ensures the disc cams into the seat without sliding friction during the final degrees of closure, minimizing wear and ensuring long-term sealing integrity.

- Bidirectional Sealing: Properly designed metal-seat valves can seal pressure from either direction.

- Lower Operating Torque (vs. gate valves): Especially in the eccentric design.

Usage Scenarios:

- Power Generation: Feedwater, steam, condenser cooling water, flue gas desulfurization (FGD) slurry lines.

- Oil & Gas: Refining process lines, hydrocarbon transfer, offshore platforms.

- Chemical & Petrochemical: Process lines with elevated temperatures or aggressive chemicals.

- HVAC: High-temperature hot water systems.

- Steel & Pulp & Paper: Process lines with heated fluids or suspensions.

Wafer Metal-seat Butterfly Valve Standards: Materials, Design, and Connections

Material, Design, and Connection Standards

Material Standards:

- Body: ASTM A216 WCB (Carbon Steel), ASTM A351 CF8/CF8M (Stainless Steel), LCC, LCB.

- Disc: ASTM A216 WCB + Hardened Edge, ASTM A351 CF8/CF8M, with optional coatings (e.g., Stellite overlay, nickel plating).

- Seat Ring: 410/420 Stainless Steel (for D373H), 316 Stainless Steel (for D373F), or other hard alloys like Monel, Inconel.

- Stem: 17-4PH, ASTM A564 Type 630, or 416/316 SS.

- Design Standards: Primarily conforms to API 609 ("Butterfly Valves: Double Flanged, Lug- and Wafer-Type"). This is the key standard for design, pressure-temperature ratings, and testing of metal-seat butterfly valves. It also references ASME B16.34 for pressure-temperature ratings.

- Connection Standards: The wafer body dimensions are designed to fit between flanges per:

- ASME B16.5 (for ANSI Class 150, 300, etc.)

- EN 1092-1 (DIN) (for PN10, PN16, PN25, etc.)

The face-to-face length typically complies with API 609 or ISO 5752.

How to Select Wafer Metal-seat Butterfly Valve

How to Purchase

- Define Critical Service Conditions: Precisely determine: nominal size (NPS/DN), pressure class (ANSI Class/PN), operating temperature, fluid media (including abrasiveness, corrosiveness, % solids), required leakage class (e.g., API 598 Class IV/V/VI), and actuation needs.

- Select Specialized Suppliers: Source from valve manufacturers with proven expertise in metal-seated, eccentric butterfly valves and API 609 compliance. Request their API monogram license if required.

- Request Detailed Technical & Commercial Quotation: Submit an inquiry specifying all conditions. Demand a detailed response including:

- Material Trim Sheet specifying exact grades for body, disc, seat, stem.

- Pressure-Temperature Rating Chart.

- Leakage rate guarantee and test standard.

- Torque data for actuator sizing.

- Certified dimensional drawings.

- Evaluate and Place Order: Compare technical proposals, certification validity, lead time, and cost. Ensure the purchase order explicitly references API 609, material grades, test requirements, and required documentation (e.g., NDE reports for welds).

Pre-Shipment Inspection for Export Wafer Metal-seat Butterfly Valve and Key Considerations

Pre-Export Inspection and Precautions

Inspection Protocol (Rigorous due to critical service):

- Visual & Dimensional Check: Inspect for casting defects, machining quality. Verify face-to-face length, bore diameter, and bolt hole alignment per drawings.

- Material Verification: Review Material Test Reports (MTRs) for all major components, especially seat and disc alloys.

- Non-Destructive Examination (NDE): For welded seat rings or hard-faced discs, review reports of PT (Liquid Penetrant Testing) or MT (Magnetic Particle Testing).

- Witness Pressure & Seat Leakage Tests: Mandatory. Witness tests per API 598/API 609. This includes a shell test and a high-pressure seat test (usually at the rated differential pressure or per API Class). For low-leakage applications, a low-pressure (e.g., 0.6 bar) air seat test is crucial.

- Function Test: Operate the valve through full cycle (with actuator if mounted) to ensure smooth 90° operation without binding.

- Coating & Packaging Check: External coating (paint, epoxy) should be intact. Protect machined surfaces and the seat area. Valve should be shipped in the slightly open position (e.g., 10-15° open) to protect the seat from impact or constant pressure.

Precautions:

- Protect Sealing Surfaces: Use rigid plastic/metal seat protectors that bolt onto the flange faces to prevent damage to the precision seat and disc edge during handling and transit. This is critical.

- Secure Internal Components: Ensure disc is firmly fixed to prevent movement during shipping.

- Complete Documentation Dossier: The shipment must include: MTRs, NDE reports, certified test reports (signed by inspector), assembly drawings, installation manual, and packing list.

- Export Packaging: Use sturdy wooden crates with proper bracing. Clearly mark "Protect Sealing Faces," "Do Not Use Lifting Lugs on Disc/Stem," and standard shipping symbols.

Wafer Metal-seat Butterfly Valve Main dimensions(mm)

| DN | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 700 | 800 | 900 | 1000 | 1200 |

| L | 43 | 46 | 49 | 56 | 64 | 70 | 71 | 76 | 83 | 92 | 102 | 114 | 127 | 154 | 165 | 190 | 203 | 216 | 254 |

| D1 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 355 | 410 | 470 | 525 | 585 | 650 | 770 | 840 | 950 | 1050 | 1170 | 1390 |

| D2 | 102 | 122 | 138 | 158 | 188 | 212 | 268 | 320 | 378 | 438 | 490 | 550 | 610 | 725 | 795 | 900 | 1000 | 1115 | 1330 |

| n-Фd | 4-ɸ18 | 4-ɸ18 | 4-ɸ18 | 4-ɸ18 | 4-ɸ18 | 4-ɸ22 | 4-ɸ22 | 4-ɸ26 | 4-ɸ26 | 4-M24 | 4-M27 | 4-M27 | 4-M30 | 4-M33 | 4-M33 | 4-M36 | 4-M36 | 4-M39 | 4-M45 |

Note:1. Other specifications and flange standards are available upon request.

- Design and specifications are subject to change without prior notice.

We also supply fire valve and water valves.

.png)

.png)