WCB Flange Ball Valve

WCB Flange Ball Valve Definition and Components

What is a WCB Flange Ball Valve and its main parts?

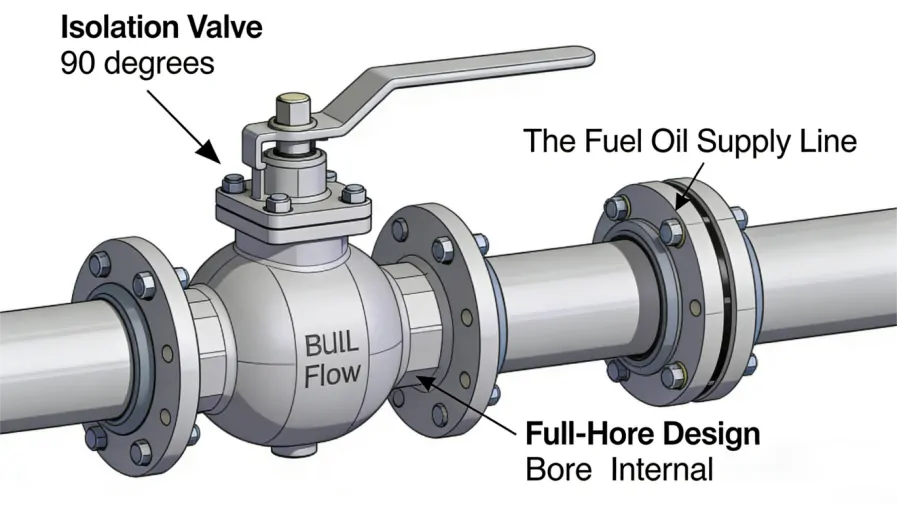

A WCB Flange Ball Valve is a quarter-turn, on/off valve designed for reliable isolation in industrial pipelines. The "WCB" designates its primary material: the body and other major pressure-containing parts are made of ASTM A216 Grade WCB, a standard carbon steel casting suitable for temperatures from -29°C to 425°C. "Flange" refers to its connection type, featuring integral flanges for bolting directly to pipeline flanges. Its core component is a rotating ball with a through-hole.

Flange Ball Valve Main Parts:

- Body: The main pressure-retaining housing, cast from ASTM A216 WCB, with integrated flanges at each end.

- Ball: A sphere with a cylindrical through-hole (bore). In a full-bore design, the bore matches the pipe ID; in a reduced-bore design, it is smaller. The ball surface is often chrome-plated or coated for hardness and corrosion resistance.

- Stem: The shaft that connects the actuator to the ball, transmitting torque. It features a blow-out-proof design.

- Seats: Upstream and downstream sealing rings (typically PTFE, reinforced PTFE, or metal) that form a seal against the ball.

- Seals & Packing: Stem seals (e.g., graphite, PTFE) and body seals to ensure tightness.

- Actuator Mounting Pad: A standardized interface (ISO 5211) for mounting manual levers, gear operators, or pneumatic/electric actuators.

- Flanges: Integral to the valve body, conforming to ASME or DIN standards for connection.

Role, Characteristics, and Application Scenarios of WCB Flange Ball Valve in Pipelines

Functions, Operational Features, Usage Scenarios, and Scenario Diagram

Functions: Provides quick, positive shut-off and on/off control. Full-bore versions allow for pipeline pigging and minimize pressure drop.

Operational Features:

- Quarter-Turn Operation: Fast 90-degree operation.

- Low Torque & Easy Operation: Requires relatively low operating torque.

- Excellent Sealing: Provides bubble-tight shut-off with soft seats.

- Minimal Maintenance: Simple design with few moving parts

- Good Flow Control (On/Off only): Not recommended for throttling as partial opening can erode seats and the ball.

- Usage Scenarios: Widely used in general industrial services requiring reliable isolation.

- Oil & Gas: Fuel lines, utility piping, process isolation.

- Power Generation: Feedwater, cooling water, and air systems.

- Chemical & Petrochemical: Process lines with non-severe corrosive fluids.

- Water Treatment & Distribution: Pump isolation, mainline valves.

- General Industrial Plant Utilities (steam, air, water

WCB Flange Ball Valve Standards: Materials, Design, and Connections

Material, Design, and Connection Standards

Material Standards:

- Body, Bonnet, Flanges: ASTM A216 Grade WCB.

- Ball & Stem: AISI 304/316 Stainless Steel, often with chrome plating or ENP coating.

- Seats & Seals: PTFE, RPTFE, PEEK, or Metal (for high-temp).

- Gaskets & Bolting: As per the flange standard.

Design Standards:

- API 6D (Pipeline Valves) or ISO 17292 (Petroleum and natural gas industries) are common for design and manufacturing.

- ASME B16.34: Defines pressure-temperature ratings and wall thickness.

- Fire-Safe Design: Often complies with API 607/API 6FA standards.

Connection Standards:

- Flange Standards: ASME B16.5 (Class 150, 300, 600) for North American markets or EN 1092-1 (DIN) (PN10, PN16, PN25, PN40) for European markets.

- Face-to-Face Dimensions: Typically per ASME B16.10 or ISO 5752.

How to Select WCB Flange Ball Valve

How to Purchase

- Define Specifications: Determine size (NPS/DN), pressure class (e.g., Class 150, 300), temperature, fluid media, and required bore type (full or reduced). Specify actuation (manual lever, gear, or automated).

- Identify Qualified Suppliers: Source from reputable industrial valve manufacturers or distributors with proven quality systems (e.g., ISO 9001, API Q1). For critical service, API 6D monogram holders are preferred.

- Request Technical Documentation: Ask for detailed datasheets, material specifications, pressure-temperature charts, and certified dimensional drawings. For fire-safe requirements, request certification (API 607/6FA).

- Evaluate & Order: Compare technical compliance, certifications, lead time, and price. The purchase order must explicitly state material (ASTM A216 WCB), design standard (e.g., API 6D), flange standard, and any special testing requirements.

Pre-Shipment Inspection for Export WCB Flange Ball Valve and Key Considerations

Pre-Export Inspection and Precautions

Inspection Protocol:

- Visual & Dimensional Check: Inspect for casting defects and damage. Verify flange dimensions (drilling, face type) against the specified standard using templates.

- Material Verification: Review Material Test Reports (MTRs) for the WCB body casting and other critical components.

- Pressure Testing (Critical): Witness shell hydrostatic test (1.5x rated pressure) and seat leakage test (usually at 1.1x rated pressure with air or water) per API 598/ISO 5208/API 6D standards. This confirms body integrity and shut-off capability.

- Function Test: Cycle the valve several times from fully open to closed. Operation must be smooth, and the position indicator must be accurate.

- Coating & Packaging Check: Check external paint/coating. Ensure robust packaging with proper flange protectors.

Industrial valves Precautions:

- Ship in Slightly Open Position: Ship with the ball about 10% open (not fully closed) to relieve pressure on the seats and prevent cold welding or deformation.

- Protect Flange Faces & Seals: Install rigid plastic or metal flange protectors bolted onto the flanges. This is essential to prevent damage to the sealing faces and bolt holes.

- Secure Actuator: If pre-mounted, ensure the actuator is immobilized to prevent unintended ball rotation during transit.

- Complete Documentation: Ensure the shipment includes: Inspection and Test Reports (ITRs), MTRs, Certificate of Conformity, packing list, and installation manual. Place in a waterproof envelope inside the crate.

- Export Packing: Use sturdy, seaworthy wooden crates. Securely brace the valve inside to prevent movement. Clearly mark crates with handling instructions ("Lift Here," "Keep Dry"), gross weight, and "Protect Flange Faces."

WCB Flange Ball Valve Function and specification

| Type

|

Nominal pressure (MPa)

|

Testing pressure | Suitable temperature (C) | Suitable medium | |

| Strength(Water) (MPa) | Enclose(Water) (MPa) |

||||

| Q41F | 1.6 | 2.5 | 4.0 | <150 | Nitric acid |

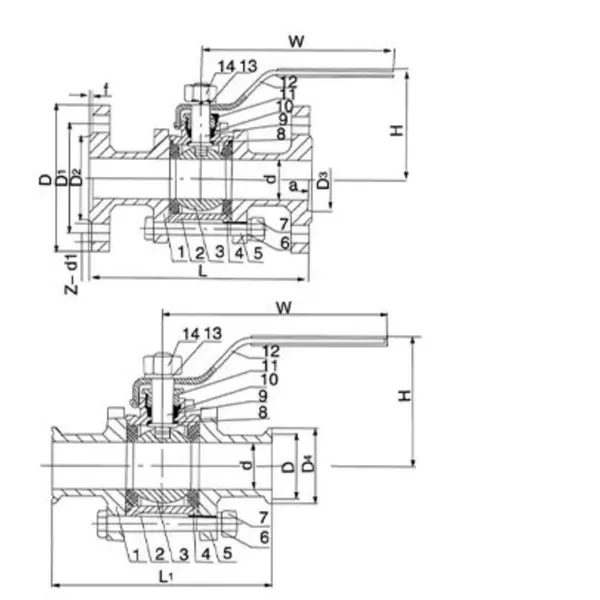

Outline and connecting measurement

| DN | Flange End(JB/T971)

Clamp End |

Clamp End | |||||||||||||

| d | L | H | D | D1 | D2 | f | a | D3 | Z | d1 | W | D | D4 | L1 | |

| 15 | 15 | 130 | 77 | 95 | 65 | 45 | 2 | 4 | 40 | 4 | 14 | 130 | 43.5 | 50.5 | 108 |

| 20 | 20 | 150 | 77 | 105 | 75 | 55 | 2 | 4 | 51 | 4 | 14 | 130 | 43.5 | 50.5 | 130 |

| 25 | 25 | 160 | 88 | 115 | 85 | 65 | 2 | 4 | 58 | 4 | 14 | 130 | 43.5 | 50.5 | 138 |

| 32 | 32 | 180 | 113 | 135 | 100 | 78 | 2 | 4 | 66 | 4 | 18 | 180 | 43.5 | 50.5 | 152 |

| 40 | 40 | 200 | 132 | 145 | 110 | 85 | 3 | 4 | 76 | 4 | 18 | 230 | 56.5 | 64 | 166 |

| 50 | 50 | 230 | 142 | 160 | 125 | 100 | 3 | 4 | 88 | 4 | 18 | 400 | 56.5 | 64 | 198 |

| 65 | 65 | 290 | 172 | 180 | 145 | 120 | 3 | 4 | 110 | 4/8 | 18 | 400 | 83.5 | 91 | 230 |

| 80 | 80 | 310 | 182 | 190 | 160 | 135 | 3 | 4 | 121 | 4/8 | 18 | 640 | 96 | 106 | 249 |

| 100 | 100 | 350 | 250 | 215/230 | 180/190 | 122/160 | 3 | 4.5 | 150 | 4/8 | 18/23 | 1100 | |||

We also supply fire valve and water valves.

.png)

.png)