Hot Products

-

ZSFZ Wet Alarm Valve

Alarm Check Valve is core element in wet pipe fire sprinkler systems. it serves a dual purpose which prevents a reverse flow of water (non-return), also provides for the use of the water motor gong. Meanwhile, in the event of variable pressure condition,false alarm is prevented with provision of retard chamber at the external bypass.

- Standard: ANSI/BS/GB

- Connection: Flange as ANSI B16.1/EN 1092-2

- Installation:Vertical

- Test: Factory hydro test 350 psi (2.4MPa)

- Temperature: 4'℃ to 70%℃

- W. pressure: 175/300 psi (1.21/2.07MPa)

-

ZSFZ Wet Alarm Valve

Alarm Check Valve is core element in wet pipe fire sprinkler systems. it serves a dual purpose which prevents a reverse flow of water (non-return), also provides for the use of the water motor gong. Meanwhile, in the event of variable pressure condition,false alarm is prevented with provision of retard chamber at the external bypass.

- Standard: ANSI/BS/GB

- Connection: Flange as ANSI B16.1/EN 1092-2

- Installation:Vertical

- Test: Factory hydro test 350 psi (2.4MPa)

- Temperature: 4'℃ to 70%℃

- W. pressure: 175/300 psi (1.21/2.07MPa)

-

ZSFZ Wet Alarm Valve

Alarm Check Valve is core element in wet pipe fire sprinkler systems. it serves a dual purpose which prevents a reverse flow of water (non-return), also provides for the use of the water motor gong. Meanwhile, in the event of variable pressure condition,false alarm is prevented with provision of retard chamber at the external bypass.

- Standard: ANSI/BS/GB

- Connection: Flange as ANSI B16.1/EN 1092-2

- Installation:Vertical

- Test: Factory hydro test 350 psi (2.4MPa)

- Temperature: 4'℃ to 70%℃

- W. pressure: 175/300 psi (1.21/2.07MPa)

-

ZSFZ Wet Alarm Valve

Alarm Check Valve is core element in wet pipe fire sprinkler systems. it serves a dual purpose which prevents a reverse flow of water (non-return), also provides for the use of the water motor gong. Meanwhile, in the event of variable pressure condition,false alarm is prevented with provision of retard chamber at the external bypass.

- Standard: ANSI/BS/GB

- Connection: Flange as ANSI B16.1/EN 1092-2

- Installation:Vertical

- Test: Factory hydro test 350 psi (2.4MPa)

- Temperature: 4'℃ to 70%℃

- W. pressure: 175/300 psi (1.21/2.07MPa)

-

ZSFZ Wet Alarm Valve

Alarm Check Valve is core element in wet pipe fire sprinkler systems. it serves a dual purpose which prevents a reverse flow of water (non-return), also provides for the use of the water motor gong. Meanwhile, in the event of variable pressure condition,false alarm is prevented with provision of retard chamber at the external bypass.

- Standard: ANSI/BS/GB

- Connection: Flange as ANSI B16.1/EN 1092-2

- Installation:Vertical

- Test: Factory hydro test 350 psi (2.4MPa)

- Temperature: 4'℃ to 70%℃

- W. pressure: 175/300 psi (1.21/2.07MPa)

-

ZSFZ Wet Alarm Valve

Alarm Check Valve is core element in wet pipe fire sprinkler systems. it serves a dual purpose which prevents a reverse flow of water (non-return), also provides for the use of the water motor gong. Meanwhile, in the event of variable pressure condition,false alarm is prevented with provision of retard chamber at the external bypass.

- Standard: ANSI/BS/GB

- Connection: Flange as ANSI B16.1/EN 1092-2

- Installation:Vertical

- Test: Factory hydro test 350 psi (2.4MPa)

- Temperature: 4'℃ to 70%℃

- W. pressure: 175/300 psi (1.21/2.07MPa)

About Us

Apex Fire Tech Co.,Ltd.

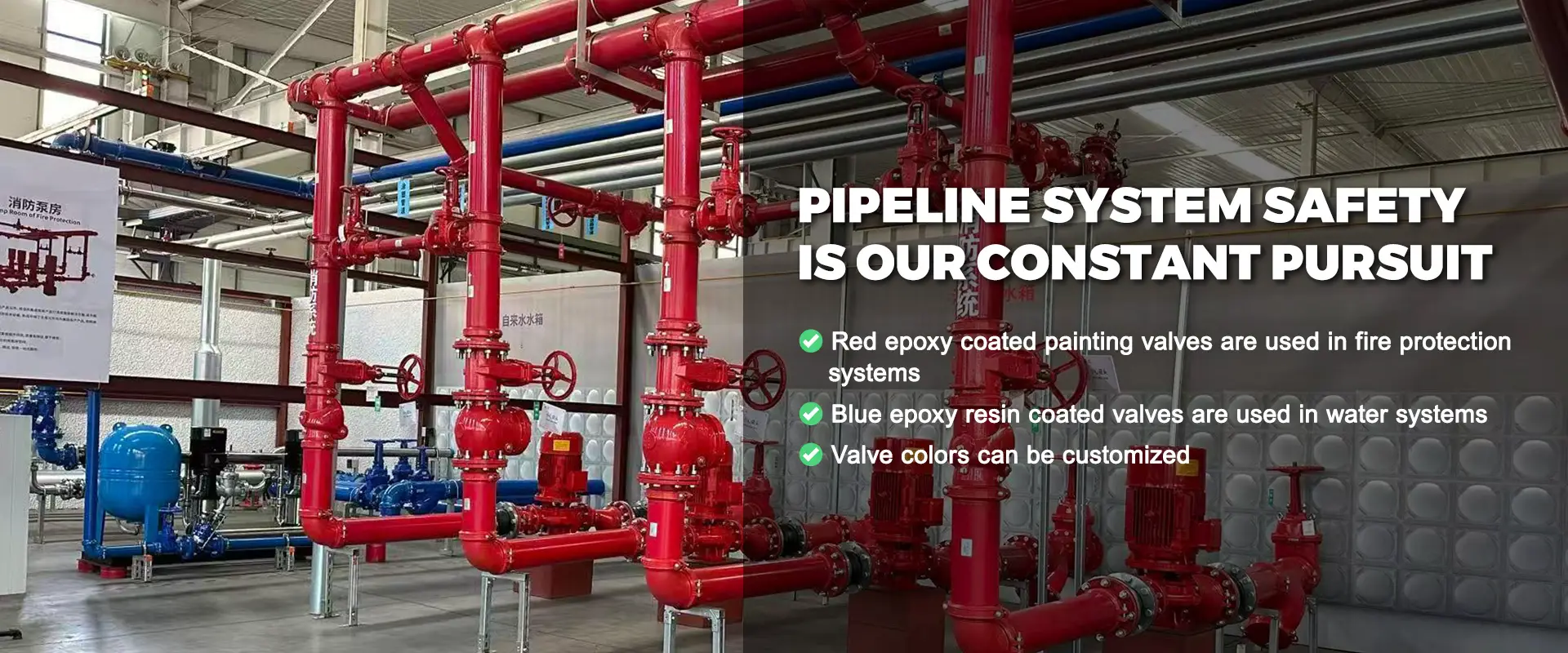

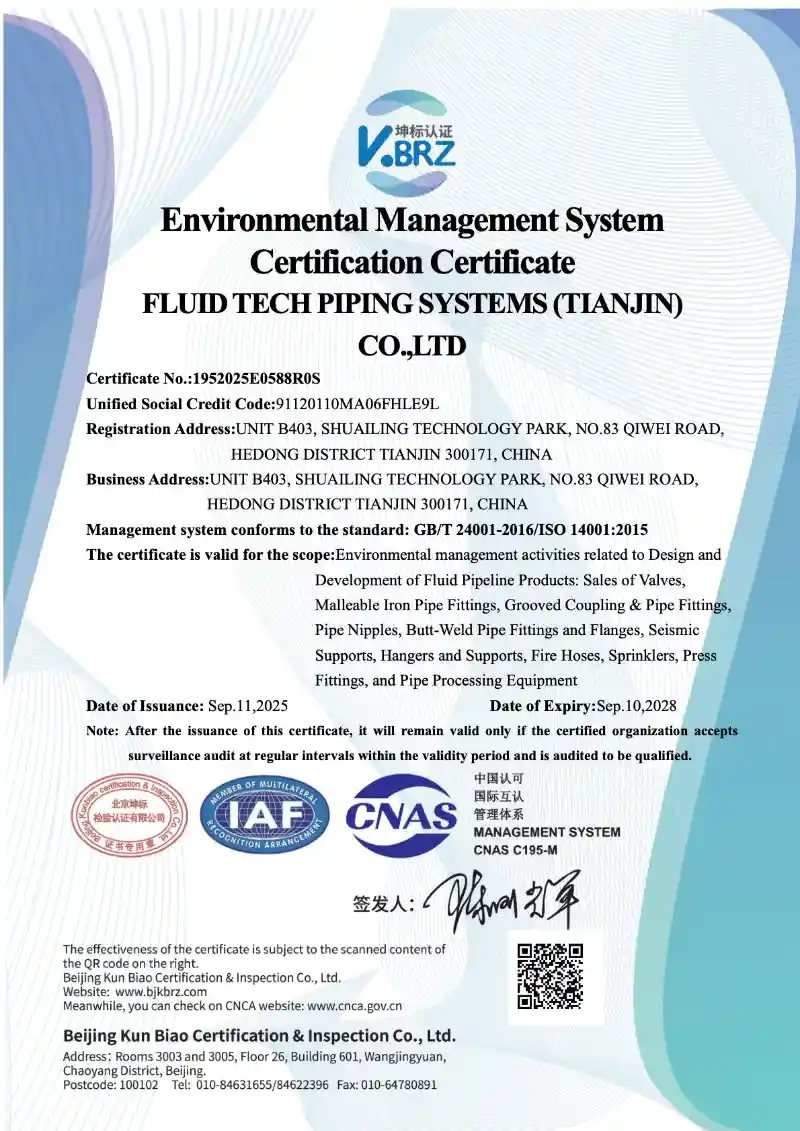

To date, the company has passed ISO, CE, and SGS factory audits, and its products are certified by WARS. Fire valves are currently applying for UL/FM certification. The FLUID TECH Group now comprises three valve product brands: FLUID TECH Brand, APEX Brand, and B Brand.

Our Advantage

Wide Product Range & Global Reach

Complete valve sizes (DN15–DN4500) and materials, exported worldwide to major markets.

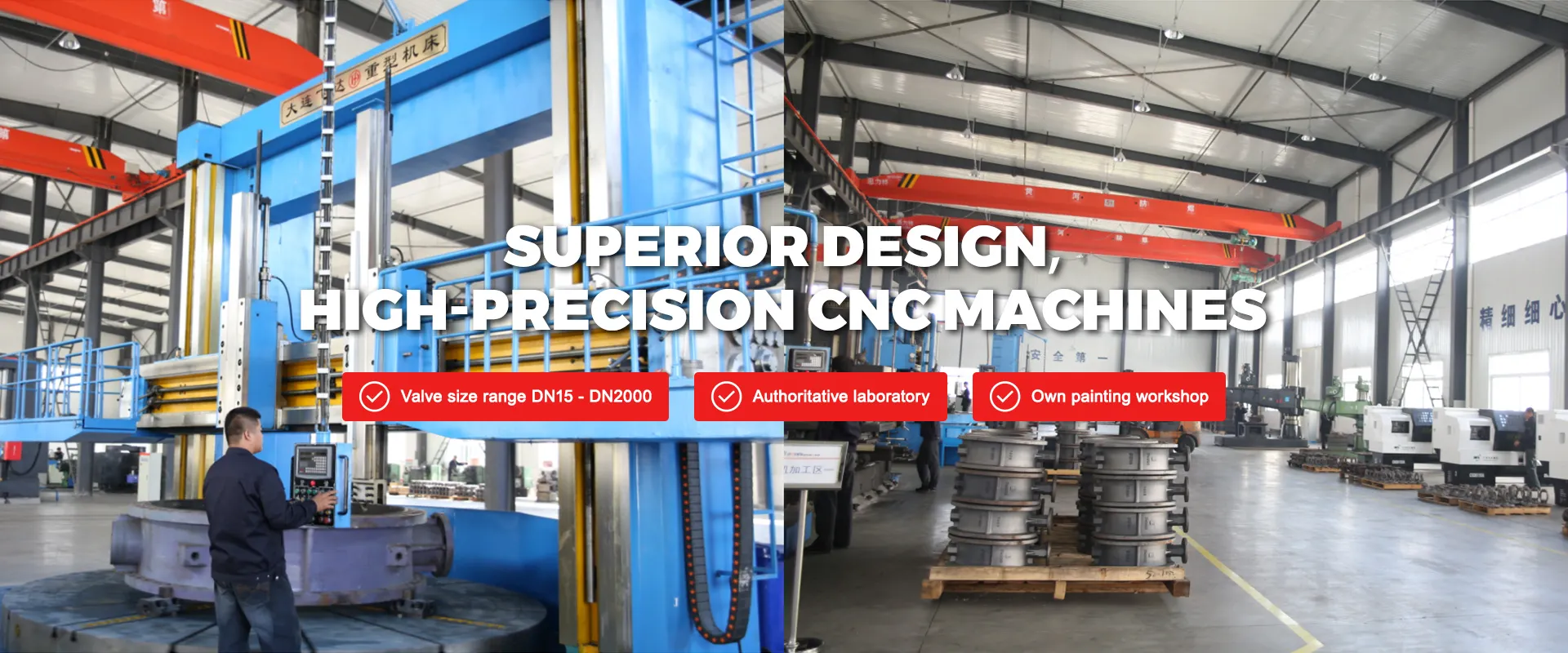

Professional R&D & High-Precision Manufacturing

300+ molds, OEM support, advanced casting and CNC machining, with 100% pressure-tested valves.

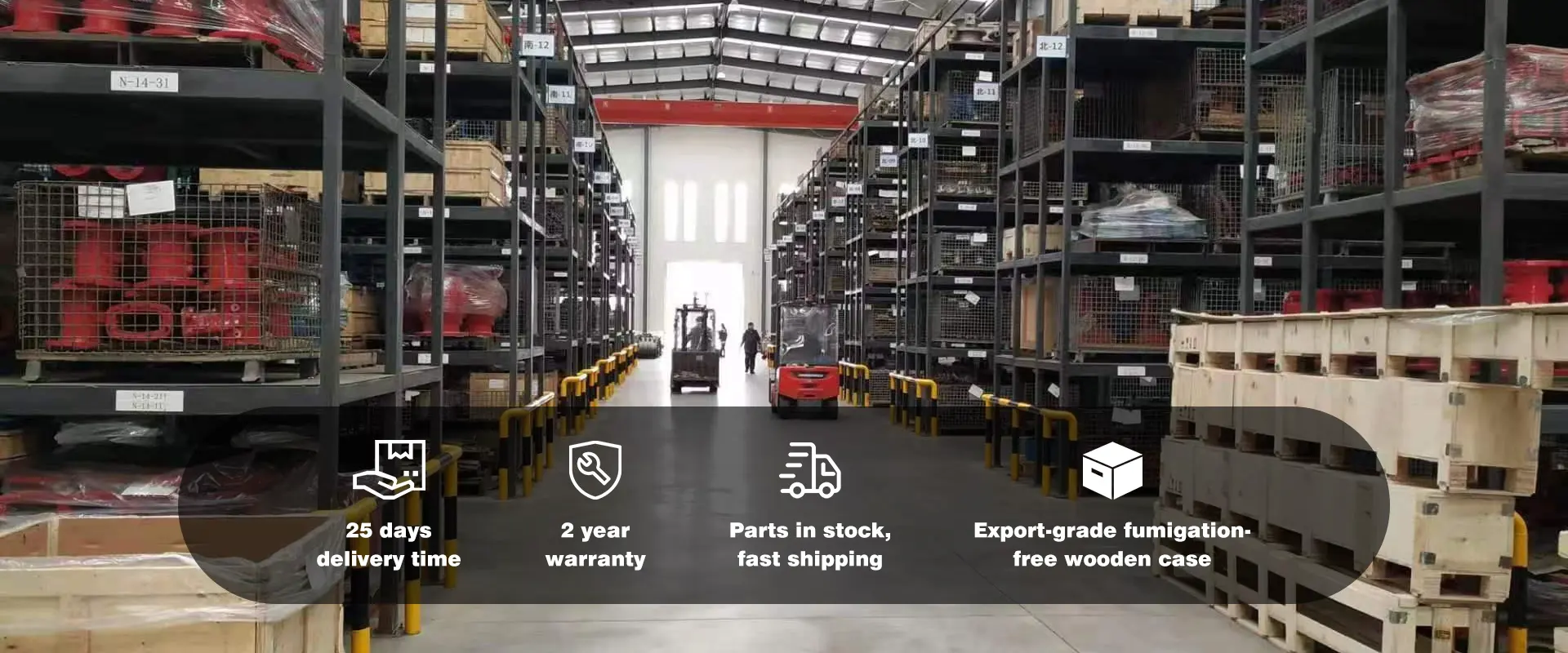

Fast Delivery & Stable Supply Chain

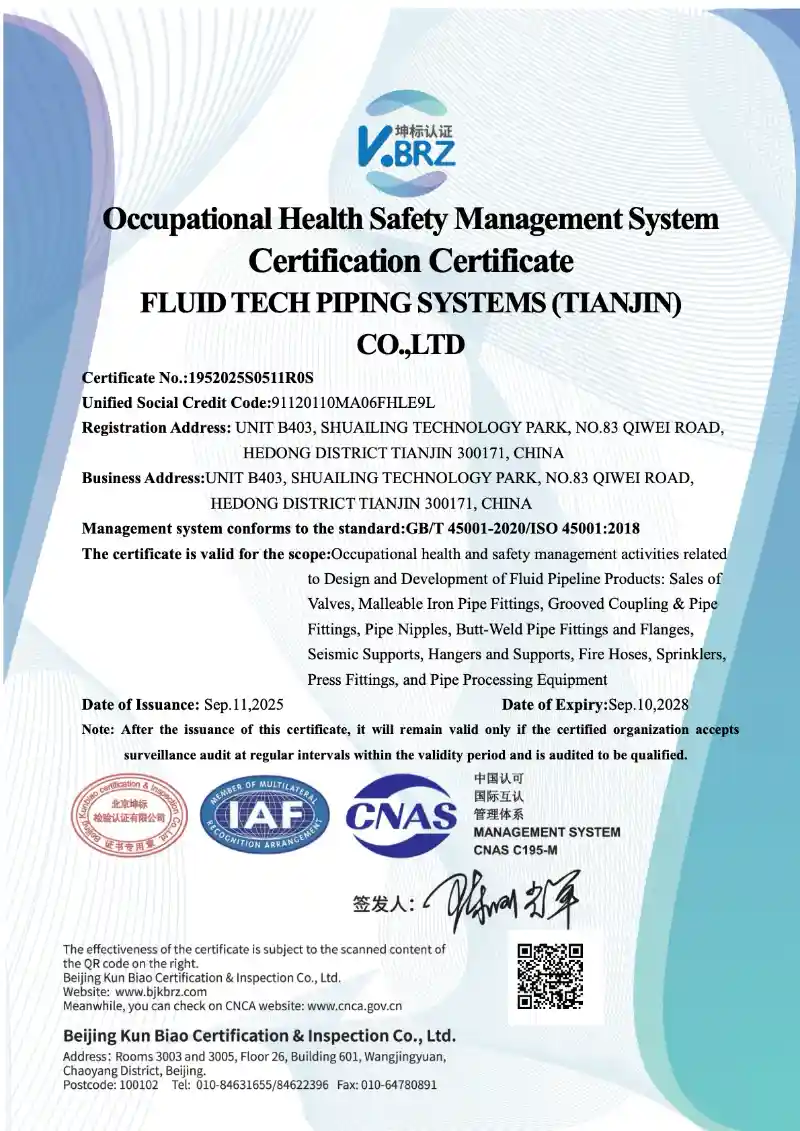

Strong inventory support, standard delivery in 25 days, urgent orders in 7 days, backed by a CNAS-certified lab.

Reliable Quality & Cost-Effective for Customers

Strict QC system, over 10-year warranty, helping clients reduce costs and improve competitiveness.

Our Certificates

New Arrivals

Latest News

-

News Title

description

.png)

.png)