2 Piece Threaded Ball Valve

2 Piece Threaded Ball Valve Definition and Components

What is a 2-Piece Threaded Ball Valve and its main parts?

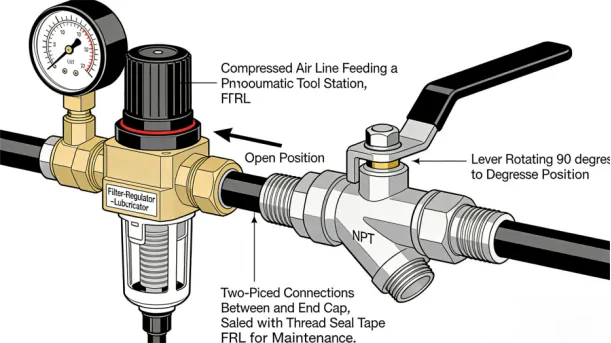

A 2-Piece Threaded Ball Valve is a compact, economical quarter-turn valve designed for on/off isolation in small to medium diameter piping systems. Its defining construction feature is a body made from two primary pieces (typically a main body section and an end cap) that are threaded or bolted together, with threaded (screwed) end connections (NPT or BSP) for pipeline installation. It offers a good balance of durability, simplicity, and cost.

Main Parts:

- Two-Piece Body Assembly: Consists of the main body (containing one threaded end and the ball/seat assembly) and a removable end cap (containing the second threaded end). These are joined by a central threaded connection or bolts.

- Ball: A chrome-plated brass, stainless steel, or carbon steel sphere with a through-hole (port). It can be full-port or reduced-port.

- Stem: A shaft connected to the ball that transmits torque from the handle. It features a blow-out-proof design.

- Seats: Sealing rings (usually PTFE, reinforced PTFE, or nylon) that form a seal between the ball and the body.

- Stem Seals & Packing: O-rings or packing around the stem to prevent leakage.

- Handle/Lever: For manual quarter-turn operation. The handle often indicates valve position (parallel to pipe = open, perpendicular = closed).

Role, Characteristics, and Application Scenarios of 2 Piece Threaded Ball Valve in Pipelines

Functions, Operational Features, Usage Scenarios, and Scenario Diagram

Functions: Provides reliable on/off isolation and flow diversion (for multi-port valves) in low to medium-pressure systems. It is not designed for throttling.

Operational Features:

- Quick Operation: Quarter-turn (90°) open/close action.

- Compact & Lightweight: Easier to install in tight spaces compared to flanged valves.

- Moderate Maintenance: The two-piece design allows for some internal inspection and seat replacement by removing the end cap, without removing the entire valve from the pipeline.

- Lower Cost: Generally more economical than three-piece or flanged ball valves.

- Usage Scenarios: Ideal for a wide range of general utility services.

- Industrial Plumbing: Compressed air, water, oil, and gas lines.

- Process Instrumentation: Isolating gauges, transmitters, and sample points.

- HVAC Systems: Chilled water, heating lines.

- Equipment & Machinery: As a supply shut-off valve.

Irrigation & Water Distribution.

2 Piece Threaded Ball Valve Standards: Materials, Design, and Connections

Material, Design, and Connection Standards

Industrial valves Material Standards:

- Body & End Cap: ASTM B62 (Bronze), ASTM A216 WCB (Carbon Steel), CF8/CF8M (Stainless Steel 304/316), or Brass UNS C36000/C37700.

- Ball: Chrome-plated Brass, 304/316 SS, or carbon steel with coating.

- Seats & Seals: PTFE (Teflon), RPTFE, Nylon, Viton.

- Design Standards: General industry designs based on:

- API 6D (as a reference for design principles).

- ASME B16.34 for pressure-temperature ratings.

- Fire-Safe Standards: Some may comply with API 607.

Connection Standards:

- Thread Standards: ASME B1.20.1 (NPT - National Pipe Taper) is most common in North America. ISO 7-1 (BSPT - British Standard Pipe Taper) is common in Europe and Asia.

- Pressure Ratings: Typically Class 150 or Class 300 for steel valves, lower for bronze/brass.

How to Select 2 Piece Threaded Ball Valve

How to Purchase

Define Basic Requirements:

- Size (e.g., 1/2", 3/4", 1" NPT).

- Material (Brass for general use, Stainless for corrosion, Carbon Steel for strength).

- Pressure & Temperature of your system.

- Fluid media (water, oil, gas, mild chemicals).

- Port type (Full or Reduced Bore).

- Identify Suppliers: Source from reputable valve distributors, industrial suppliers, or direct manufacturers. Check for compliance with common standards.

- Request Product Specifications: Ask for a detailed product datasheet confirming materials, pressure ratings, and temperature limits. For bulk orders, consider requesting a sample.

- Compare and Order: Evaluate based on material quality, stated certifications, price, and delivery time. Clearly state thread type (NPT or BSP) on the purchase order.

Pre-Shipment Inspection for Export 2 Piece Threaded Ball Valve and Key Considerations

Pre-Export Inspection and Precautions

Inspection Protocol:

- Visual & Dimensional Check: Inspect for surface defects. Verify size and check thread quality with a gauge for proper form, taper, and absence of damage.

- Material Verification: For critical materials (e.g., 316SS), review mill certificates if available.

- Pressure Test: Perform a shell test (1.5x rated pressure) and a seat leakage test (1.1x rated pressure with air or water). This is crucial to validate integrity.

- Function Test: Operate the valve several times. Ensure smooth 90° operation, proper handle alignment, and no sticking.

- Packaging Check: Ensure individual valves are packaged to prevent thread damage and corrosion.

Precautions:

- Protect Threads: Essential. Fit durable plastic thread protectors on both ends. These must survive shipping and handling.

- Ship in Open Position: Prevents seats from taking a set under pressure and protects seals.

- Prevent Galvanic Corrosion: If valves are stainless steel, ensure they are not packed in carbon steel strapping or touching dissimilar metals without separation.

- Proper Documentation: Include packing list, product catalogs/certifications, and test reports (if performed) in the shipment.

- Export Packing: Use sturdy cartons or crates. For bulk orders, use pallets with valves boxed individually. Mark boxes with "Protect Threads," "Keep Dry," and the size/material.

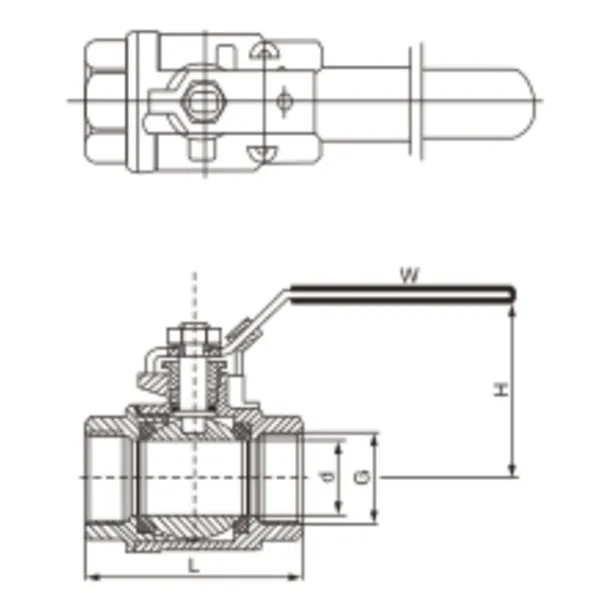

2 Piece Threaded Ball Valve Main outer size

| DN | G | D | L | H | W |

| 6 | 1/4” | 10 | 51 | 50 | 90 |

| 10 | 3/8” | 12 | 51 | 50 | 90 |

| 15 | 1/2” | 15 | 55 | 58 | 100 |

| 20 | 3/4” | 20 | 66 | 62 | 120 |

| 25 | 1” | 25 | 80 | 72 | 140 |

| 32 | 1 1/4” | 32 | 94 | 80 | 140 |

| 40 | 1 1/2” | 38 | 103 | 90 | 180 |

| 50 | 2” | 50 | 115 | 98 | 200 |

| 65 | 2 1/2” | 64 | 160 | 125 | 220 |

| 80 | 3” | 78 | 177 | 135 | 240 |

| 100 | 4” | 100 | 218 | 156 | 300 |

We also supply fire valve and water valves.

.png)

.png)