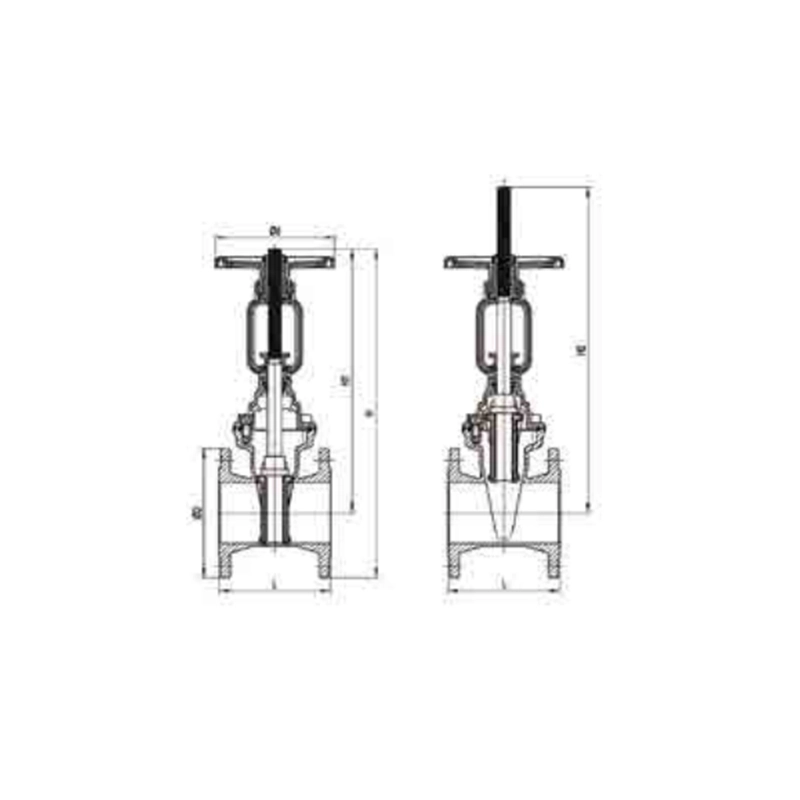

BS5163 Flanged Resilient Seated OS&Y Gate Valve

BS5163 Flanged Resilient Seated OS&Y Gate Valve Definition and Components

Definition & Main Parts

A BS5163 Flanged Resilient Seated OS&Y Gate Valve Model No. Z41X-02 is a British Standard compliant valve with Outside Screw and Yoke (OS&Y) design for waterworks applications. It features visible rising stem operation and complies with BS5163 specifications. The "Z41X-02" indicates gate valve, flanged OS&Y, resilient seated, and design variant 02.

Gate Valve OS & Y Type Main Parts:

- Valve body with BS flanges

- Resilient-seated gate

- OS&Y assembly with visible rising stem

- Yoke and yoke bushing

- Handwheel on yoke

- Adjustable gland packing system

- Body-bonnet gasket

Role, Characteristics, and Application Scenarios of BS5163 Flanged Resilient Seated OS&Y Gate Valve in Pipelines

Fire gate valve Functions:

- Mainline isolation in water distribution systems

- Pump station control valves

- Reservoir inlet/outlet valves

- Critical service where valve position must be visible

Operational Features:

- OS&Y Design: Visual stem position indication

- Easy Maintenance: Packing can be replaced under pressure

- BS5163 Compliance: Meets UK waterworks requirements

- Resilient Seat: Bubble-tight seal

- Corrosion Allowance: Minimum 4.0mm per BS5163

Fire valve Typical Applications:

- UK water utility networks

- Water treatment plant process lines

- Fire protection water systems

- Industrial water supply

- Pumping station installations

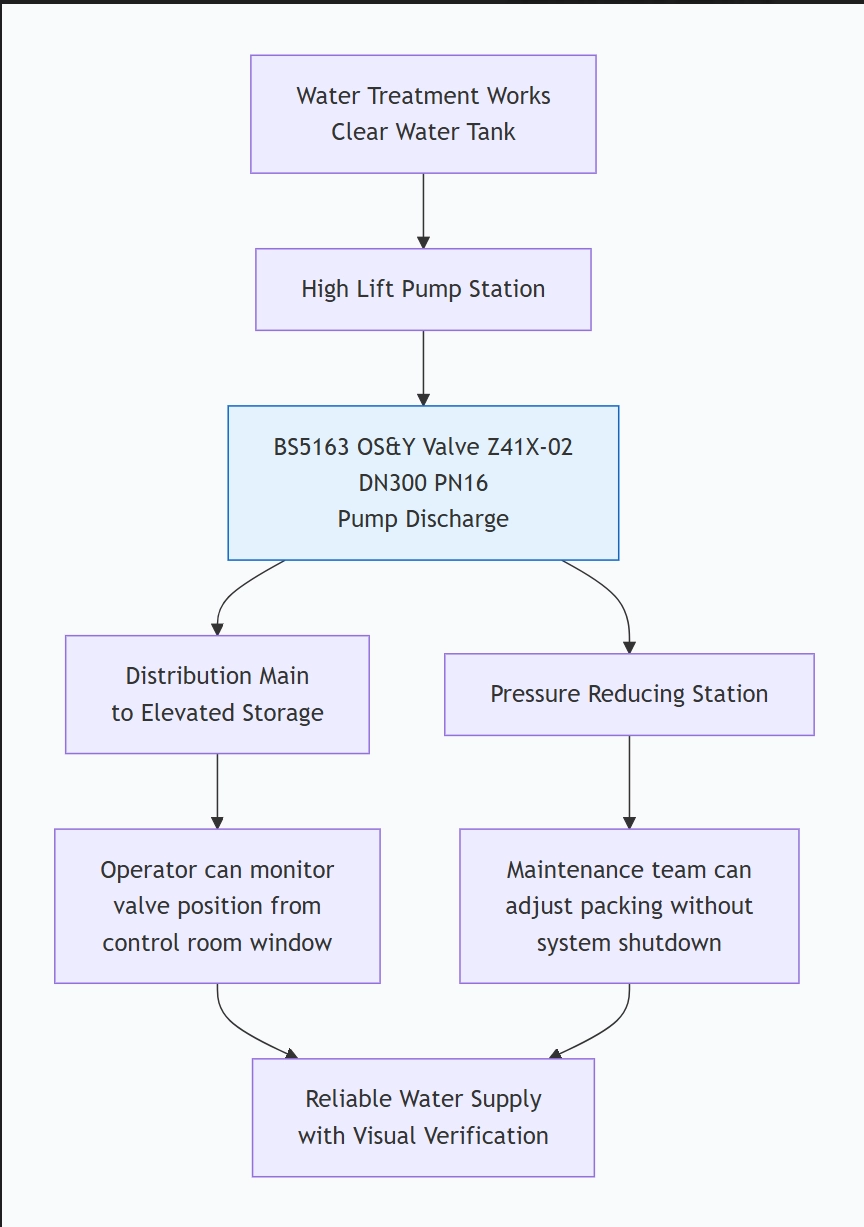

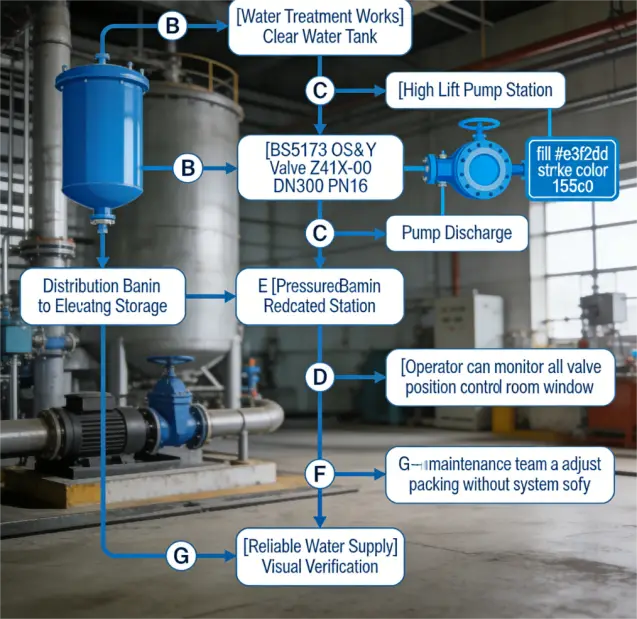

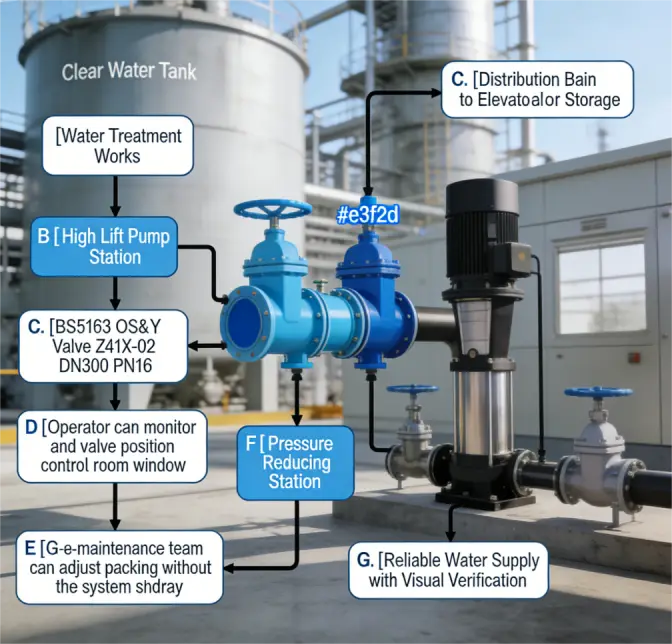

Scenario Diagram:

BS5163 Flanged Resilient Seated OS&Y Gate Valve Standards: Materials, Design, and Connections

Material Standards:

- Body/Bonnet:Ductile Iron EN-GJS-450-10(per BS EN 1563)

- Stem:Stainless Steel AISI 304/316

- Gate:Ductile iron with EPDM encapsulation

- Yoke:Cast iron or ductile iron

- Bolting:Grade 8.8 zinc plated

Design Standards:

- BS5163:2004:Primary design standard

- BS EN 12266-1:Pressure testing requirements

- BS EN 1074:Fitness for purpose for water supply

- Pressure ratings:PN10,PN16 standard

Connection Standards:

- Flanges:BS EN 1092-2 Type A(flat face)or BS4504 PN10/16

- Face-to-Face:Per BS5163 tables

- Gaskets:Full-face rubber per BS EN 1514

- Coating:Internal epoxy per BS EN 14901

How to Select BS5163 Flanged Resilient Seated OS&Y Gate Valve

Key Steps:

- Specify Requirements: Size, pressure rating (PN16 standard), WRAS approval needed

- Verify Standards Compliance: Must meet BS5163:2004

- Select Supplier: UK-based or internationally certified manufacturers

- Check Certifications: WRAS approval mandatory for UK water supply

- Review Documentation: BS5163 compliance certificate required

Critical Specifications:

- WRAS approval (Regulation 31 compliance)

- Pressure rating (PN10 or PN16)

- Flange type (Type A flat face standard)

- Internal coating specification

- Packing material type

Important Considerations:

- Ensure manufacturer has valid WRAS approval

- Verify BS5163 compliance certification

- Check lead times (typically 8-12 weeks)

- Consider local UK water company approvals

Pre-Shipment Inspection for Export BS5163 Flanged Resilient Seated OS&Y Gate Valve and Key Considerations

Documentation Check:

- BS5163:2004 Compliance Certificate

- WRAS Approval Certificate

- Material Test Reports(EN 10204 3.1)

- Hydrostatic Test Certificates

- CE/UKCA marking documentation

Physical Inspection:

OS&Y Mechanism Test

Smooth rising stem operation

Full travel verification

Yoke alignment check

Thread condition inspection

BS5163 Specific Checks

4.0mm corrosion allowance verification

Internal epoxy coating thickness(minimum 250μm)

Proper marking per BS5163 Clause 9

Flange face condition(Type A flat face)

Pressure Testing

Shell test:1.5×PN(24 bar for PN16)

Seat test:1.1×PN(17.6 bar for PN16)

Backseat test capability verification

Packing leakage test

Visual Inspection

Complete WRAS/BS5163 markings

Surface finish quality

Coating coverage

All components present

Export Packaging:

- Flange protectors:Bolt-on type for flat face flanges

- Stem protection:Thread protectors on rising stem

- VCI protection:For sea transport

- Wooden crates:Heavy-duty construction

- WRAS labels:Protected from damage

- Orientation markings:For OS&Y components

Key Precautions:

WRAS certification:Labels must remain visible and intact

Flat face protection:Ensure no damage to flange sealing surfaces

Stem protection:Prevent bending during handling

Documentation:Include all UK compliance certificates

Climate control:For humid or marine destinations

Final Shipping Documents:

Commercial Invoice

Packing List

Bill of Lading

Certificate of Origin

Technical File(BS5163 cert,WRAS approval,test reports)

Installation&Maintenance Manual

Material Certificates(EN 10204 3.1)

BS5163 Flanged Resilient Seated OS&Y Gate Valve Size Chart

.png)

.png)